Monitoring system capable of detecting gas leakage of pipelines on sickroom equipment belts

A monitoring system and equipment belt technology, applied in the direction of measuring the increase and decrease rate of fluid, measuring device, fluid tightness test, etc., can solve the problems of delaying maintenance time, increasing maintenance cost, affecting hospital use, etc., to avoid errors Alarm, reduce installation process, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

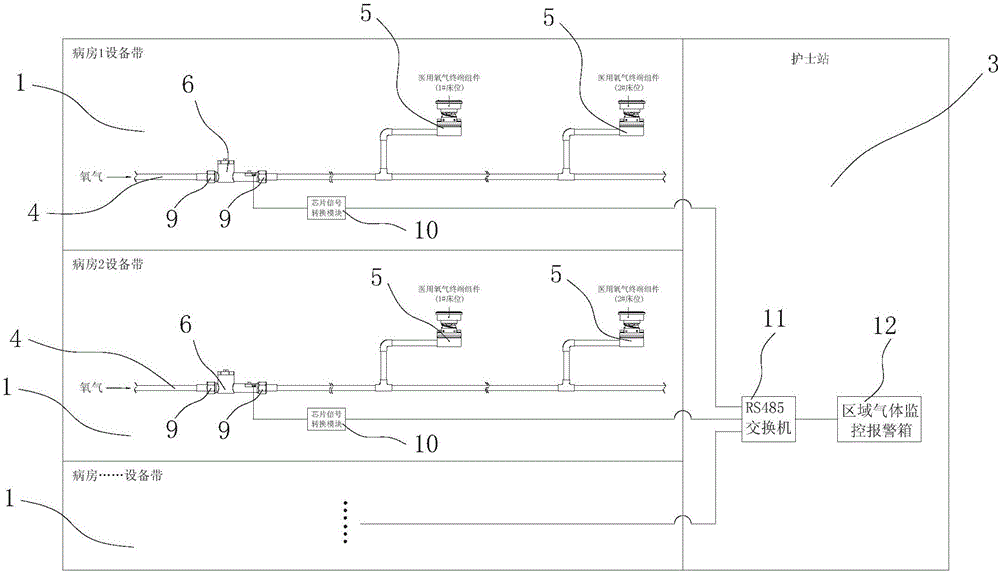

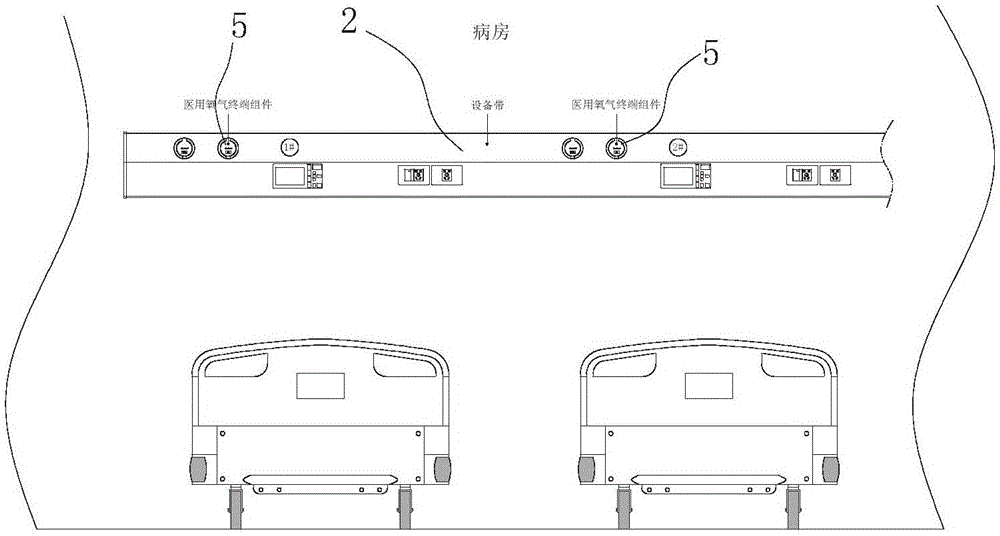

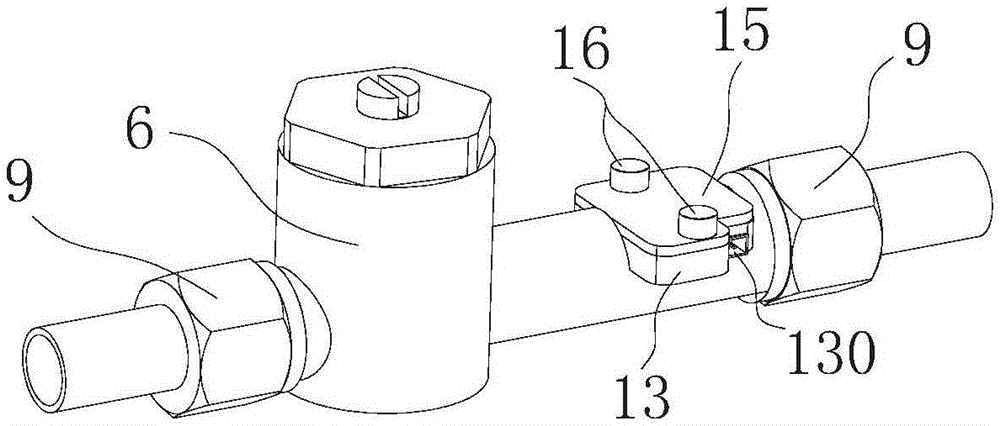

[0025] A monitoring system that can detect air leaks in ward equipment, such as Figure 1 to Figure 5 As shown, it is mainly applicable to the air leakage monitoring of medical oxygen, including a plurality of wards 1, a medical equipment belt 2 and a nurse station 3 arranged in each ward 1, and each medical equipment belt 2 is provided with an air intake pipe 4 A medical gas terminal assembly 5 for medical oxygen output respectively; a cut-off valve 6 for controlling gas on-off is arranged on the inlet pipe 4, and a flow sensor chip 7 and PCB board 8, wherein, between the air flow pipeline corresponding to the shut-off valve 6 and the pipeline on the medical equipment belt 2, the nut 9 adopts a hard-sealed connection mode that cooperates with a spherical surface and a conical surface to fix; The flow sensor chip 7 is electrically connected to the PCB board 8 and the voltage signal of each flow sensor chip is converted into a chip signal conversion module 10 of an RS485 signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com