Rolling linear guide power damper reliability testing platform and testing method

A technology of linear guide rail pair and damper, which is applied in the field of reliability test of mechanical parts, can solve problems such as the performance detection level of stop damper and the blankness of reliability test device, and achieve accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

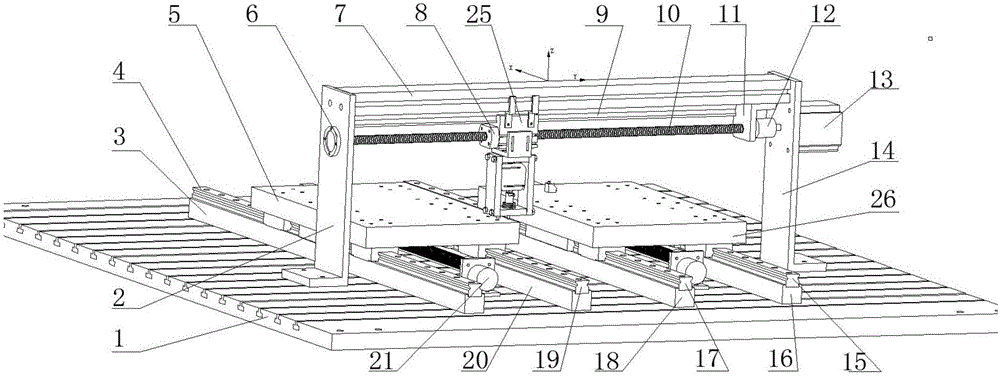

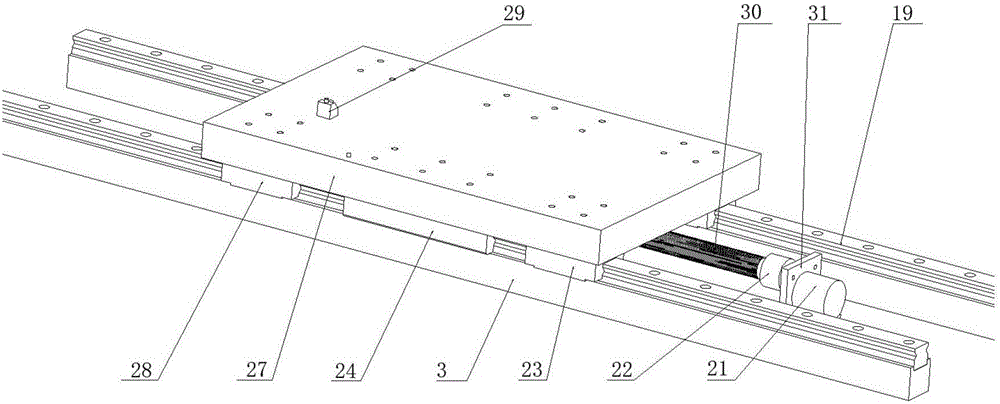

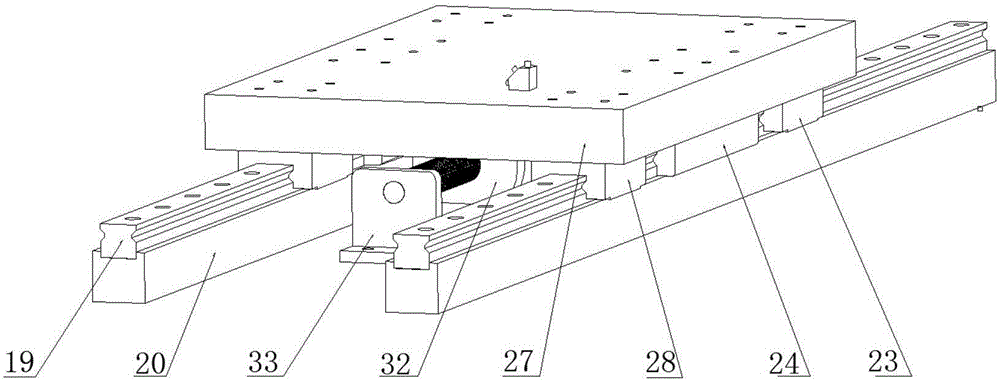

[0047] refer to figure 1 , Image 6 , a rolling linear guide rail auxiliary damper reliability test bench, the test bench includes a temperature and humidity test chamber 44 and two damper workbench I5 and damper workbench II26 with the same structure arranged inside the temperature and humidity test chamber 44, Horizontal iron 1, two X-direction feed devices with the same structure, damper loading unit support part, Y-direction feed device 25, piezoelectric ceramic loading part, damping performance detection part and automatic control part.

[0048] Wherein the horizontal iron 1 is fixed on the horizontal plane; the lower end of the support part of the damper loading unit is fixed on the horizontal iron 1; the damper table I5 and the damper table II26 are fixed on the horizontal iron 1 in parallel and arranged below the supporting part of the damper loading unit; the two X-direction feed devices are respectively arranged in the middle of the damper workbench I5 and the dampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com