Fluid film lubrication damping technical test platform

A technology of lubrication damping and test platform, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices. Accurate, novel structure, easy to install and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

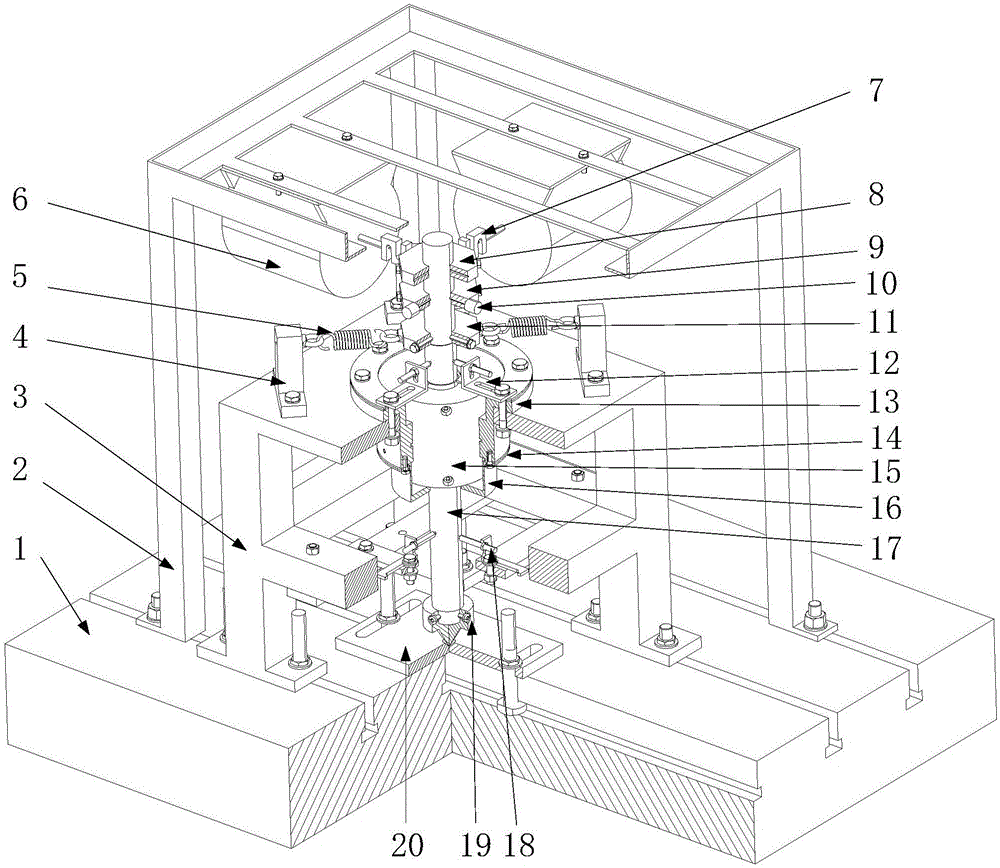

[0024] Specific embodiments of the present invention are shown in the accompanying drawings, the test platform for fluid film lubrication and damping technology includes: foundation platform 1, vibration exciter support 2, test piece support assembly, vibration exciter 6 and oil drum kit; The device bracket 2 and the test piece bracket assembly are installed on the upper part of the foundation platform 1, and the vibrator 6 is suspended and installed on the upper part of the vibrator bracket 2 through bolts; the oil drum kit is fixedly installed on the test piece bracket assembly;

[0025] The test piece support assembly includes: test piece support 3, spring support 4, force sensor support 8, sensor support 9, spring connection support 11, displacement sensor support 12, inner shaft 17, conical head 19 and support base plate 20; test piece The bracket 3 is installed on the upper part of the foundation platform 1 and located inside the vibrator bracket 2; the support base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com