Non-destructive testing method of internal structure of cigarettes during burning

A technology of internal structure and combustion process, which is applied in the field of cigarettes, can solve problems such as unintuitive, little progress in cigarette changes, and inability to reproduce the real combustion process of cigarettes well, so as to prevent looseness and fragility, overcome low strength, and ensure Effect of sample structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

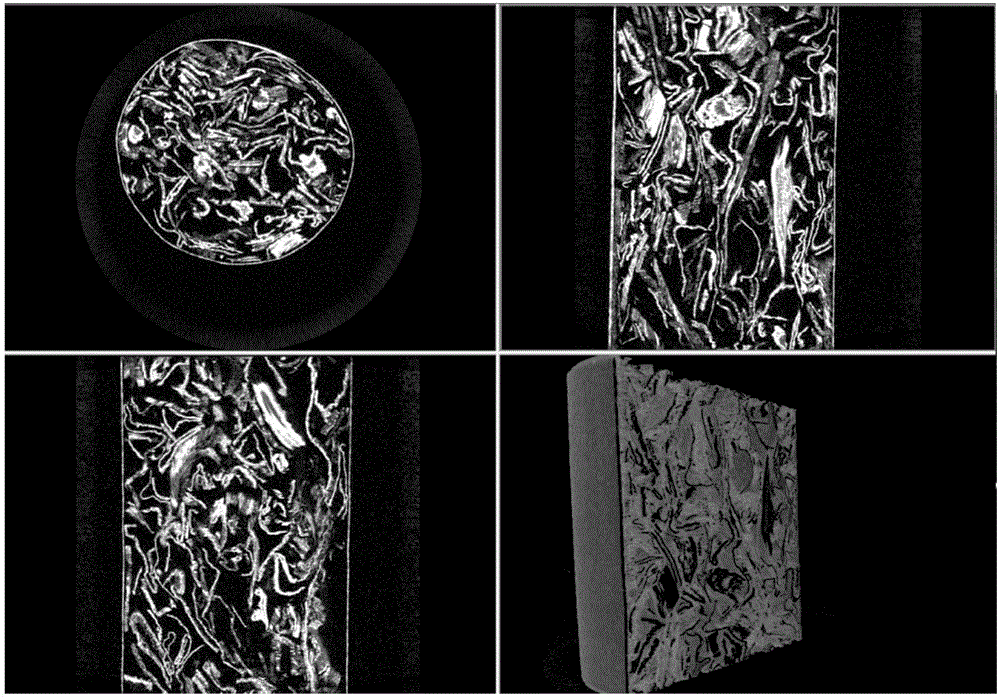

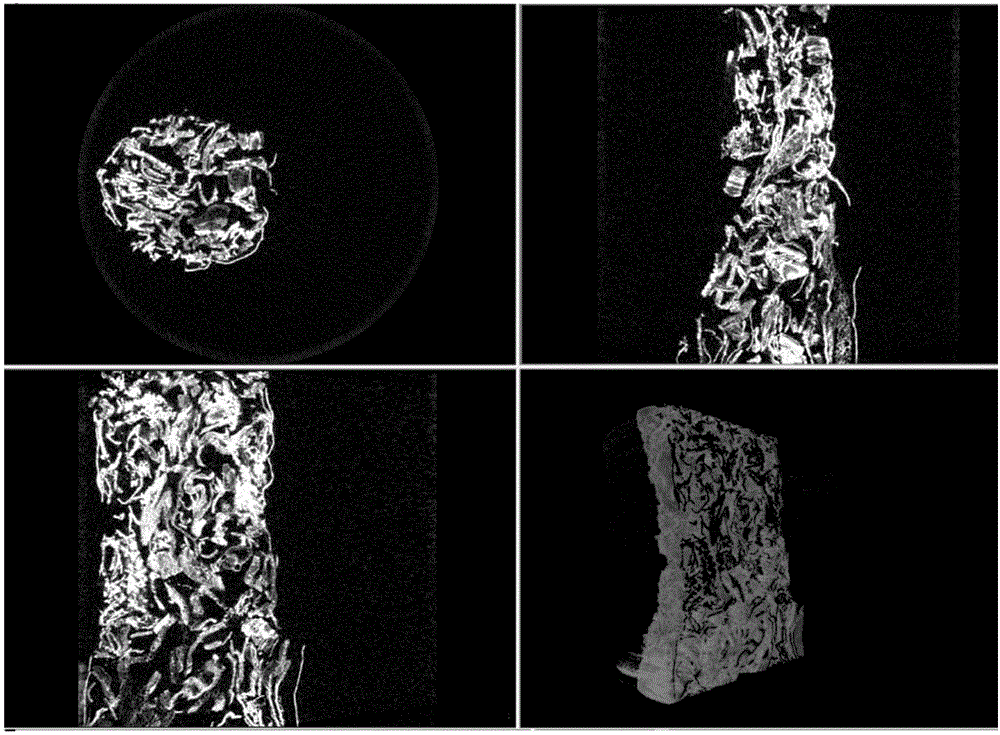

[0027] Take a cigarette sample, put it vertically into a CT scanner for scanning, and obtain the internal structure of the cigarette sample in an unburned state. Then ignite the same cigarette sample and test it in static combustion mode. When the ashes are about 2cm, gently put the cigarette into a glass sleeve (8mm in diameter and 15mm shorter than the cigarette sample) to quickly extinguish the cigarette, and Place in refrigerator for 15 minutes. The cigarette was carefully taken out to ensure that the ash package was complete, and placed in a CT scanner for scanning to obtain an image of the internal structure of the cigarette during the burning process ( figure 1 unburned cigarettes, figure 2 For cigarette ash and burning cone part). Calculated by the software, the porosity of the unburned cigarette is 37.52%, the porosity of the burning cone part is 28.32%, and the porosity of the ash-forming part is 22.63%. At the same time, the three-dimensional structure image ins...

Embodiment 2

[0029] Take a cigarette sample, put it vertically into a CT scanner for scanning, and obtain the internal structure of the cigarette sample in an unburned state. Then light the same cigarette sample, use the ISO mode test, after taking 3 puffs, put the cigarette gently into the glass sleeve (8mm in diameter, 15mm shorter than the cigarette sample), so that the cigarette is quickly extinguished, and put it in the refrigerator Freeze for 15 minutes. Carefully take out the cigarette to ensure the integrity of the ash package, place it in a CT scanner for scanning, and obtain an image of the internal structure of the cigarette during the burning process. Calculated by software, the porosity of the unburned part of the cigarette is 39.36%, the porosity of the burning cone part is 30.05%, and the porosity of the ash-forming part is 25.75%. At the same time, the three-dimensional structure image inside the cigarette can be obtained, and any cross-section can be sliced for observat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com