An Ultrasonic Visual Imaging Method for Detecting Composite Structural Rib Area

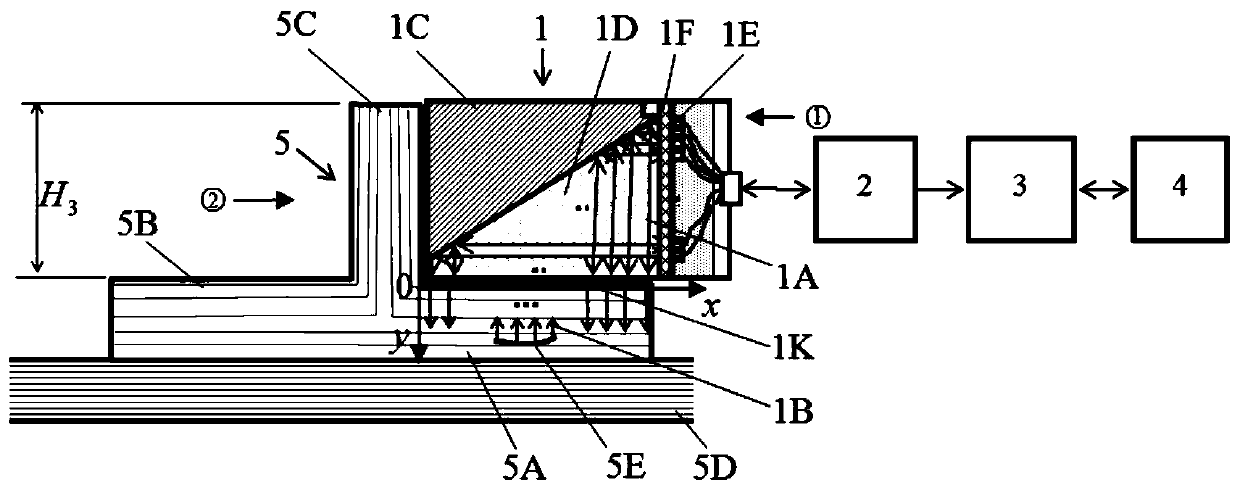

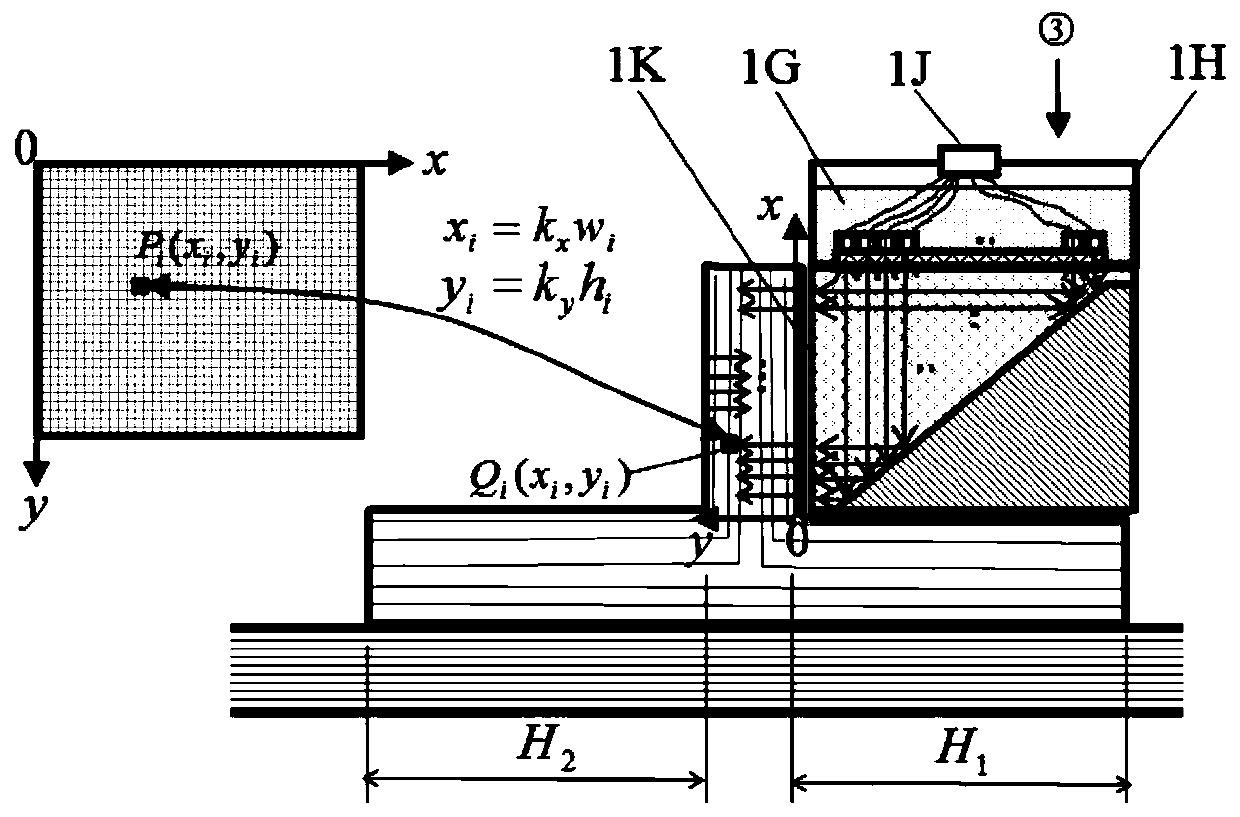

A technology of composite materials and structural ribs, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, and can solve the problems of poor real-time verification of test results, influence of subjective factors by testers, and low test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0142] Adopt the patent of this invention, choose the UBZ-1 series ultrasonic array transducer of AVIC Composite Materials Co., Ltd. and its supporting ultrasonic array unit, signal processing unit and display unit, use water as contact and non-contact coupling agent A series of actual detection applications have been carried out on different parts of the rib area of the material structure. Among them, the frequency of the transducer is 5MHz, 7.5MHz and 10MHz. The width of the rib area ranges from 20mm, 40mm, and 80mm. The series of actual test application results show that it can effectively detect the defects of Ф3mm and the delamination of Ф6mm and the pores of the glue layer in different parts of the rib area of the composite structure As well as the structural changes in the rib area, etc., the visual imaging quality is very clear, and a good actual detection effect has been achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com