Screening method of volatile organic compound in cigarette filter tip blasting-bead

A technology of volatile organic compounds and cigarette filters, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem that there are no relevant regulations on the substances in cigarette popping beads, it is not clear what substances are contained in popping beads, and there are no volatile substances in popping beads, etc. problems, to achieve the effect of rapid screening, comprehensive screening, and short detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

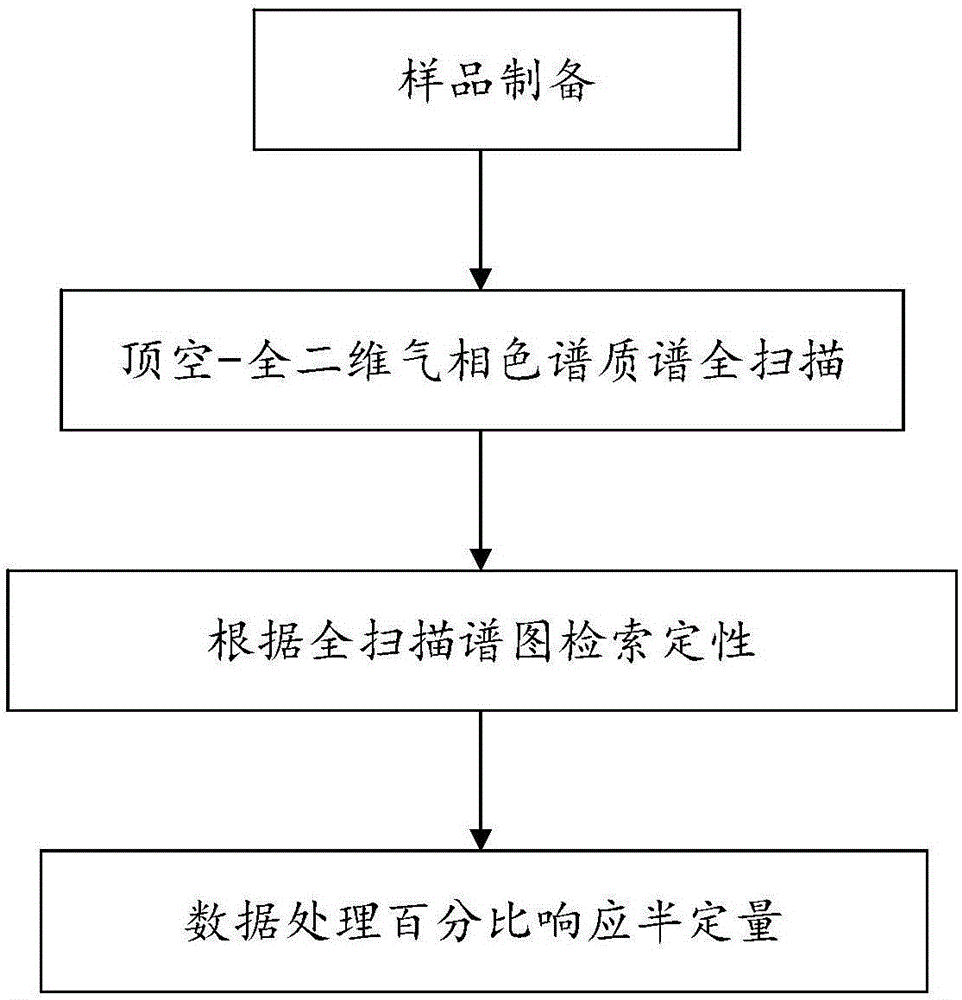

[0030] The screening method for volatile organic compounds in the cigarette filter quick-fried beads of the present embodiment, the process flow chart is as follows figure 1 shown, including the following steps:

[0031] 1) Take out two popping beads from the popping bead cigarette A, put them into a 20ml headspace bottle, puncture the popping beads with a disposable syringe, and let the liquid in the popping beads flow out; carry out headspace sampling of the liquid in the popping beads and Combined with comprehensive two-dimensional gas chromatography-mass spectrometry for full-scan analysis of the sample, the following results are obtained: figure 2 The full-scan profile shown;

[0032] Headspace sampling conditions are as follows: sample loop volume is 3.0ml, sample equilibrium temperature is 40°C, sample loop temperature is 160°C, transfer line temperature is 180°C, sample equilibration time is 20.0min, sample vial pressurization pressure is 138kPa, plus The pressure t...

Embodiment 2

[0042] The method for screening the volatile organic compounds in the puffed beads of the cigarette filter in this embodiment is aimed at the puffed puffs B, and the specific operation steps and process parameters are the same as those in Example 1.

[0043] The headspace-comprehensive two-dimensional gas chromatography mass spectrometry full scan diagram after optimizing the selected qualitative spots in this embodiment is as follows Figure 4 As shown, the test results are shown in Table 2.

[0044] Table 2 The detection results of the volatile organic compounds in the popcorn cigarette B

[0045]

[0046]

Embodiment 3

[0048] The method for screening the volatile organic compounds in the popcorn of the cigarette filter in this embodiment is aimed at the popcorn C. The specific operation steps and process parameters are the same as those in Example 1, and the test results are shown in Table 3.

[0049] Table 3 The detection results of the volatile organic compounds in the popcorn cigarette C

[0050]

[0051]

[0052] As can be seen from the above results, in the full scan diagram obtained by the screening method of the present invention, the separation of the target chromatographic peak and the impurity chromatographic peak is good, and the limited detection of harmful components and effective fragrance components in the popcorn can be realized; at the same time, the entire detection The cycle only takes about 45 minutes, which can effectively and quickly screen the ingredients of popping pearls in popping pearls cigarettes to ensure the safety of popping pearls cigarette products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com