A hollow turntable sample feeding device

A turntable-type, sample-feeding technology, applied in the direction of analyzing materials, instruments, chemical analysis using combustion, etc., can solve the problems of the automatic sample-feeding device being not compact in structure, occupying a large space and occupying a large space, and achieving stepless control and rotation. Speed, reasonable structure design, the effect of reducing the total occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

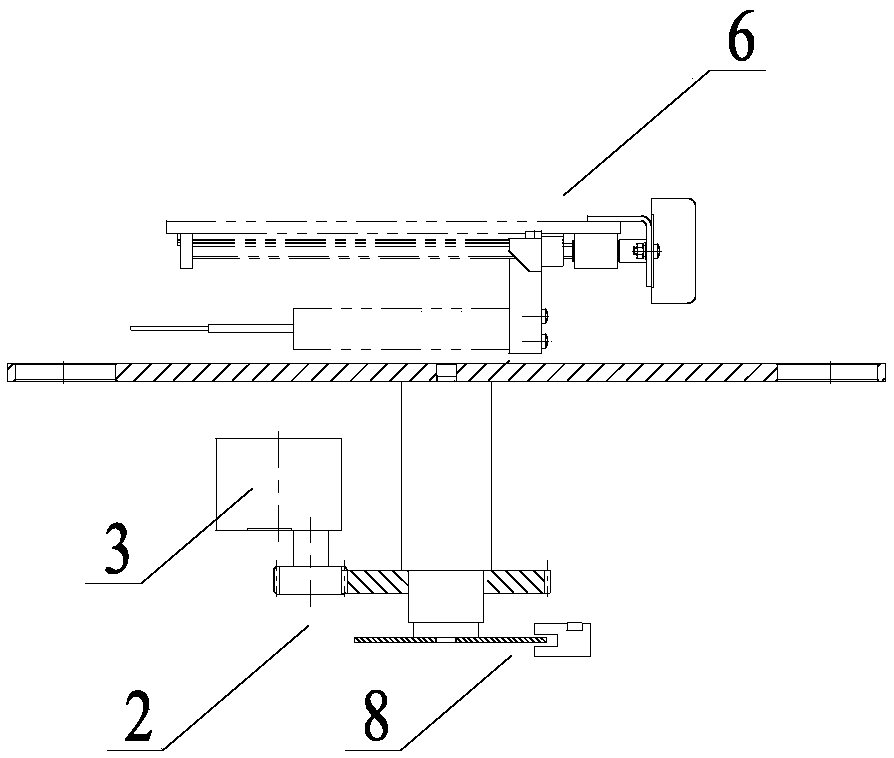

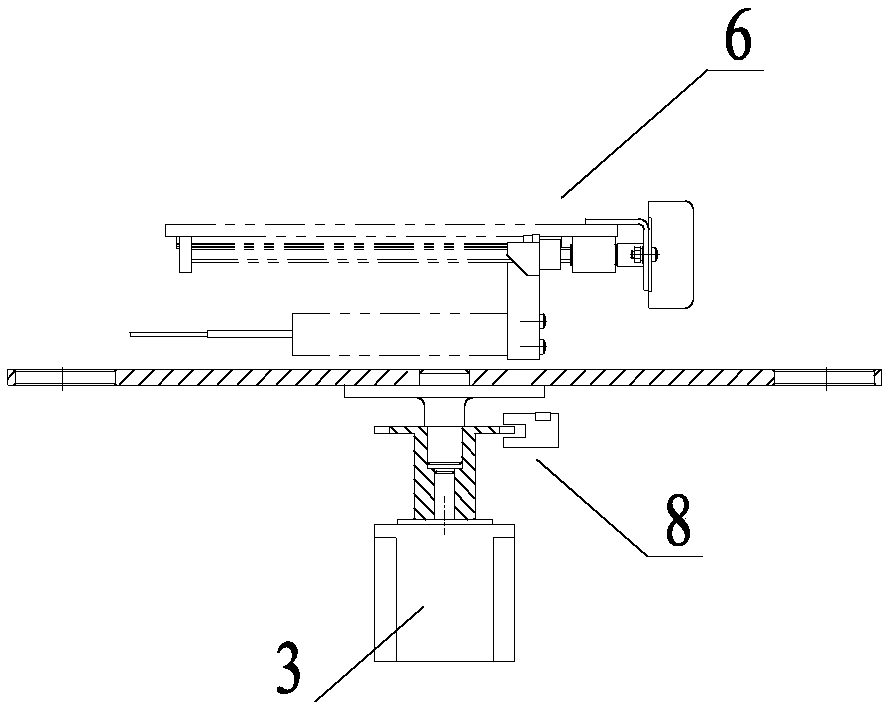

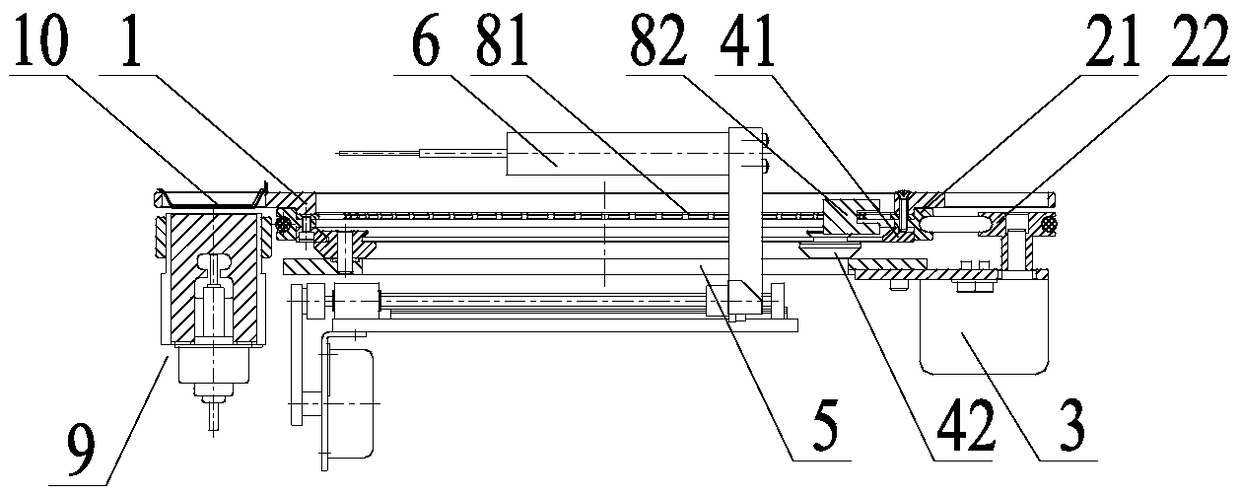

[0035] Such as Figure 4 As shown, the hollow turntable sample delivery device provided by Embodiment 1 of the present invention includes a ring-shaped stakeout table 1, a transmission assembly 2, a drive assembly 3, a guide assembly 4, a mounting plate 5, a retractable manipulator 6, a control assembly 7, Indexing component 8 and lifting component 9.

[0036] Such as Figure 5 As shown, the annular lofting table 1 is uniformly provided with a number of sample positioning through grooves 11 along the circumferential direction; the transmission assembly 2 includes a first transmission member 21 and a second transmission member 22, the first transmission member 21 and the second transmission member 21 The second transmission member 22 is a belt pulley, the first transmission member 21 and the second transmission member 22 are rotationally connected by a belt, and the outer diameter of the first transmission member 21 is larger than the outer diameter of the second transmission membe...

Embodiment 2

[0042] The hollow turntable sample feeding device provided in the second embodiment of the present invention is similar to that in the first embodiment, except that the transmission assembly 2 includes a first transmission member 21 and a second transmission member 22. The first transmission member 21 and the second transmission member 22 are a pair of gears that mesh with each other, and the outer diameter of the first transmission member 21 is larger than the outer diameter of the second transmission member 22; the lifting assembly 9 is a miniature hydraulic cylinder, arranged in the ring The shape lofting table 1 is directly below the telescopic direction of the telescopic manipulator 6.

[0043] The working process of the hollow turntable sample delivery device provided in Embodiment 2 of the present invention is similar to that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com