Phase-field-model-based study method of using laser to control silicon substrate surface morphology

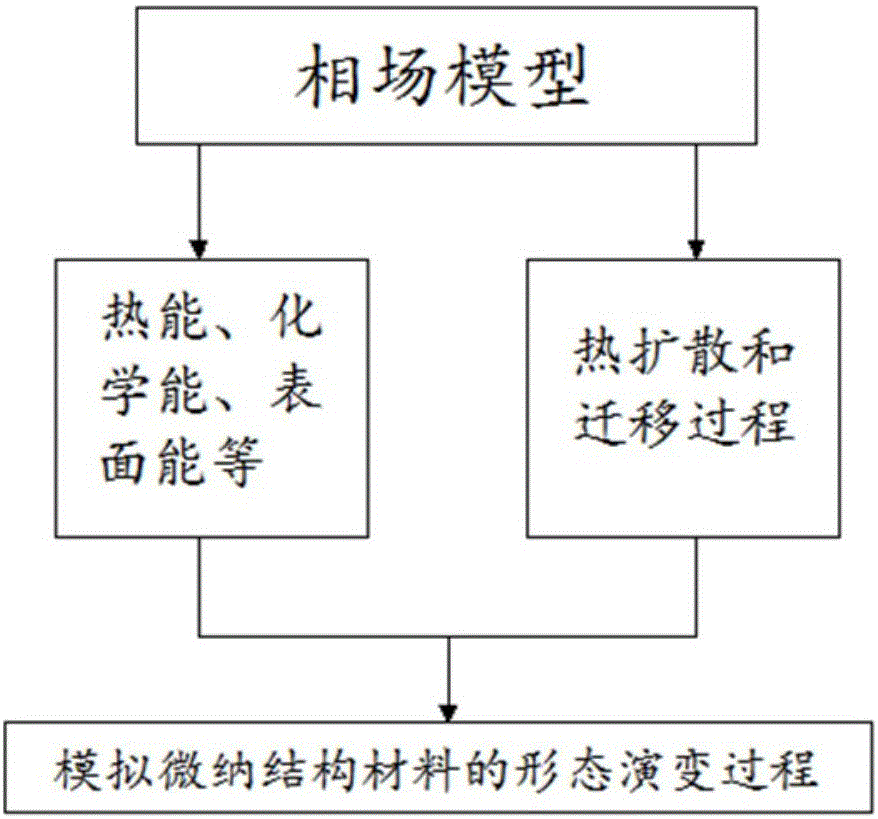

A surface morphology and model technology, applied in the field of nano-manufacturing, can solve problems such as limitations in understanding silicon-based surface morphology, and achieve the effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

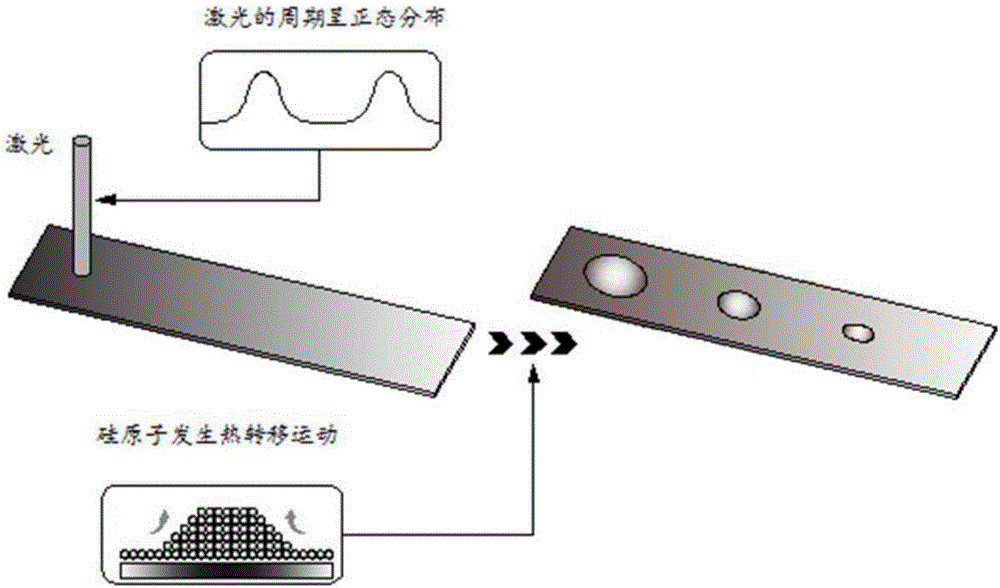

[0039] A brief introduction to the silicon-based surface forming mechanism of the silicon substrate is given. When the laser (the frequency is Gaussian distribution) irradiates the left end of the silicon substrate, the temperature of the silicon substrate will change, which will cause the silicon atoms to undergo thermal diffusion and move in a direction along one direction, making it in a stable state. state, eventually forming the figure 1 The morphology of the silicon-based surface is shown.

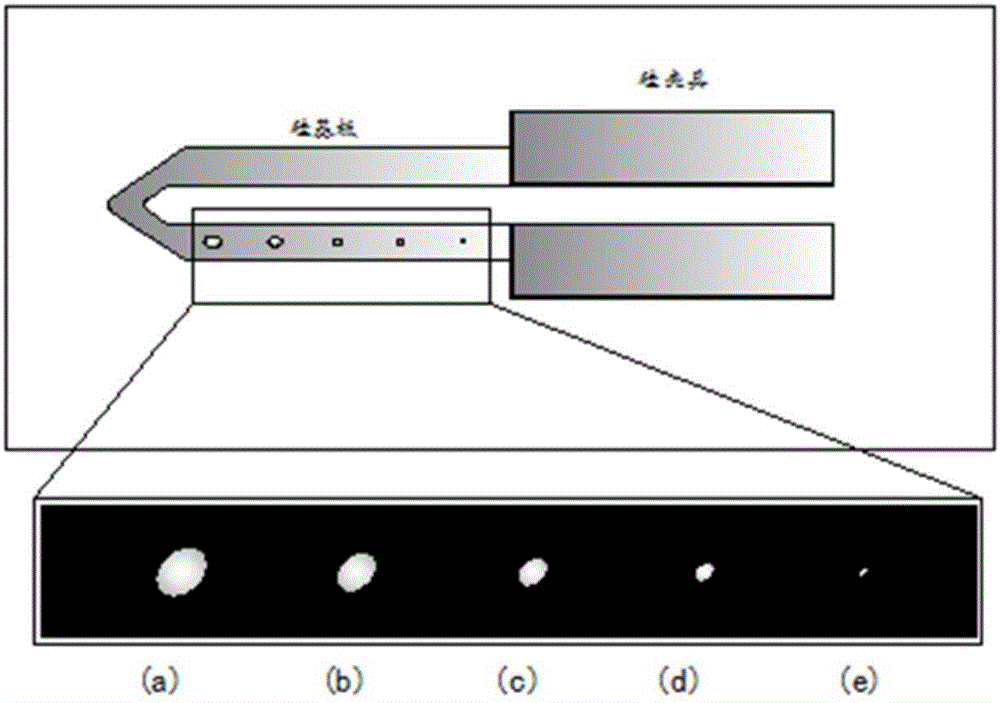

[0040] The experimental device platform is built under the AFM (atomic force microscope), which mainly includes micro-nano-sized silicon fixtures (silicon-made fixtures for fixing silicon substrates) and laser emitters. Take a silicon substrate of micro-nano size, clamp the right end of the silicon substrate on the silicon fixture, and irradia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com