Optical pump magnetometer gradient tolerance measuring device

A technology of optical pump magnetometer and measuring device, which is applied to measuring devices, measuring electrical variables, instruments, etc., can solve the problems of undisclosed testing methods and devices, and achieve the effect of high degree of automation and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with accompanying drawing:

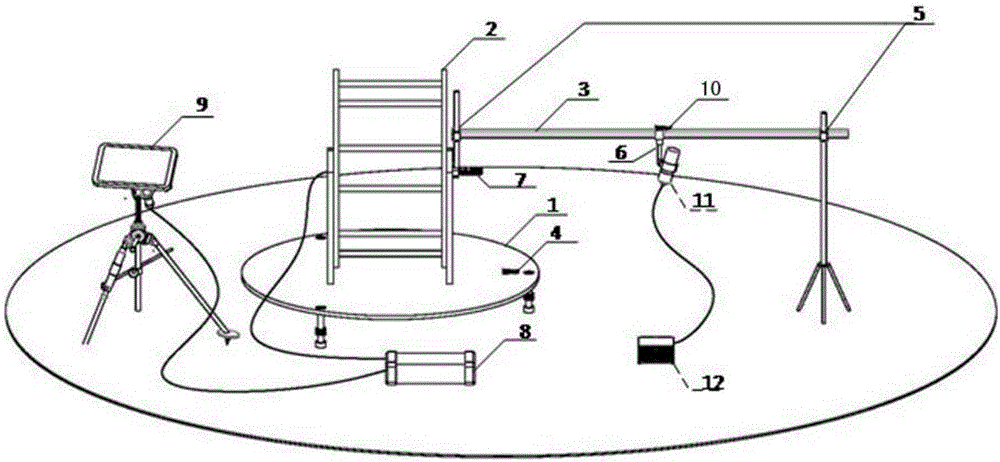

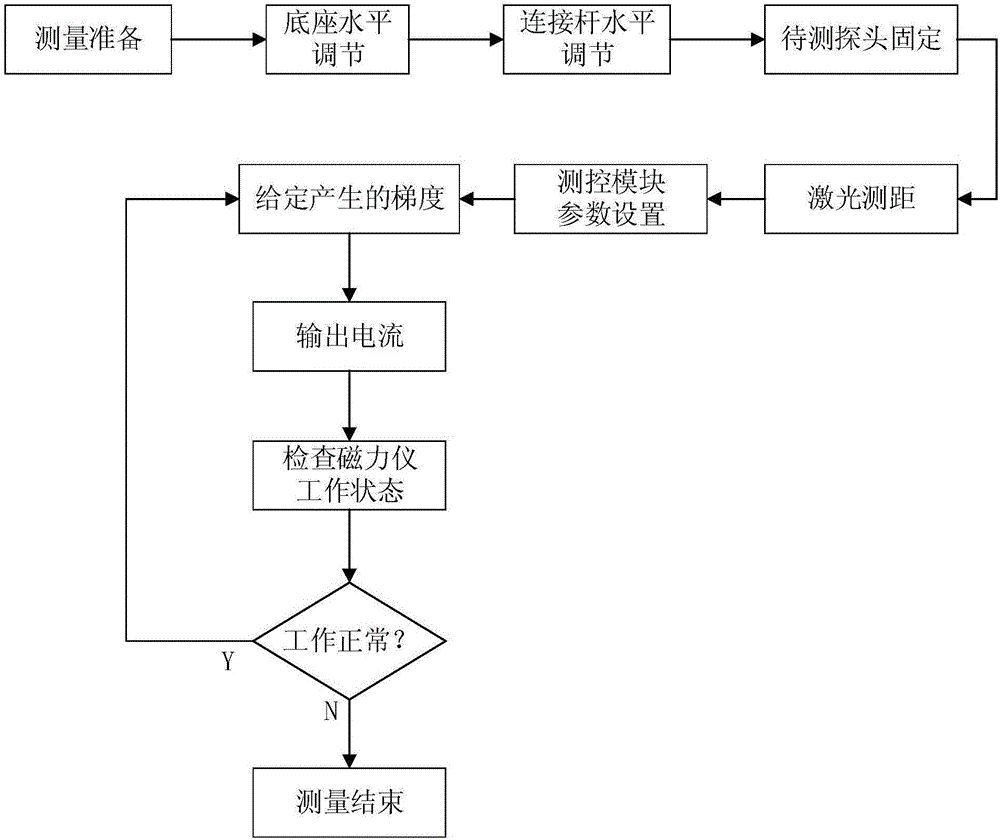

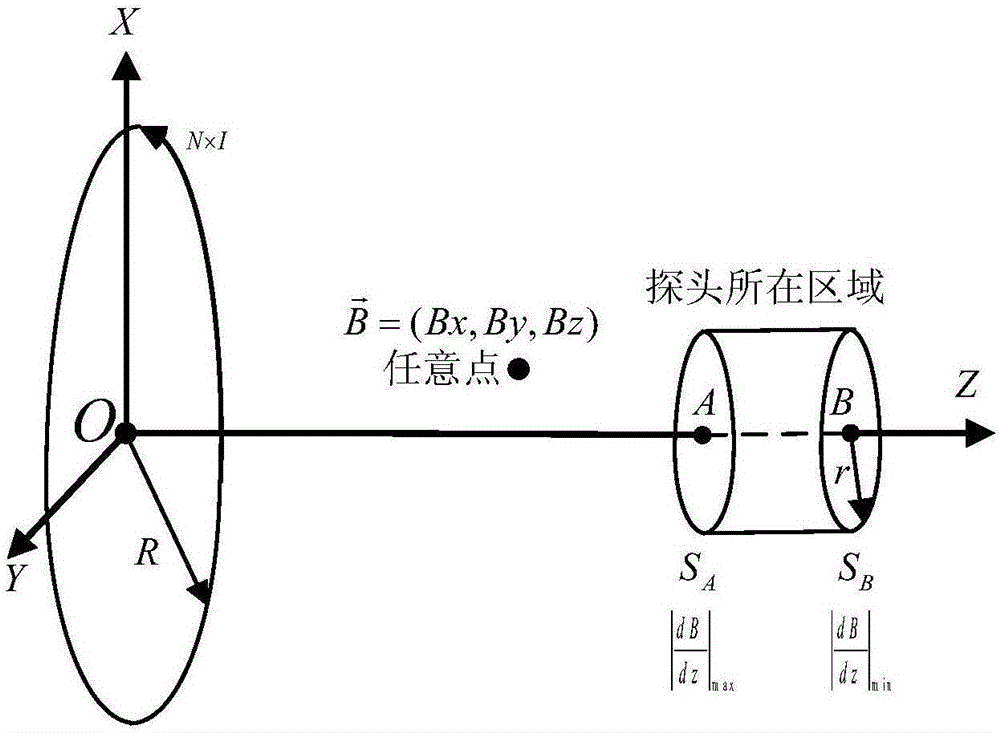

[0015] The optical pump magnetometer gradient tolerance measuring device according to the present invention mainly includes a horizontal base 1, a gradient generating coil 2, a horizontal connecting rod 3, a bubble level 4, a connecting rod level adjustment device 5, and an optical pump probe mounting fixture 6 , a laser range finder 7, a precision current source 8, and a measurement and control module 9; the measurement and control module 9 calculates the output current required to generate a specific magnetic gradient according to the preset parameters of the probe position, probe size, coil turns, and coil radius, and passes The USB interface controls the precise current source 8 to output a specific current to the gradient generating coil 2; the gradient generating coil 2 is installed on the horizontal base 1 and its position is adjusted by the bubble level A4, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com