Busbar cooling control method and device

A control device and busbar technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems that the response time and accuracy of the temperature sensor cannot be reached, it is difficult to adjust the cooling device, and it cannot be guaranteed. , to achieve the effects of heat dissipation, easy debugging, and good response adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

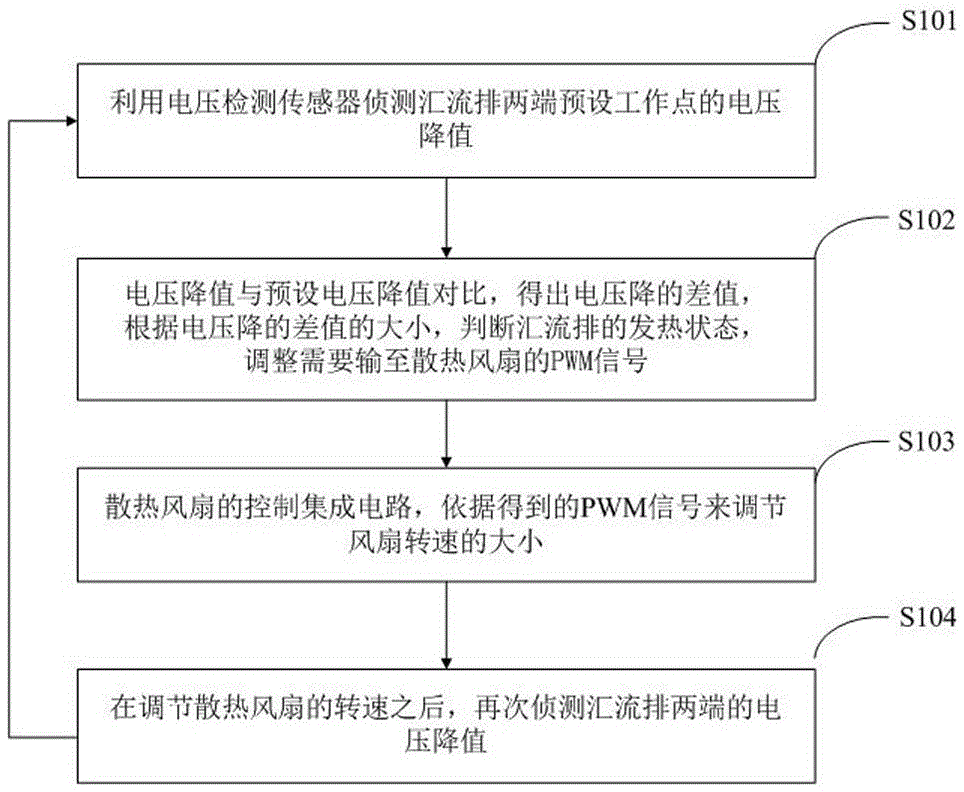

[0032] Such as figure 1 As shown, a method for regulating and controlling the heat dissipation of busbars comprises the following steps:

[0033] Step S101: Use the voltage detection sensor as the detection element in this embodiment, detect the voltage drop value at the preset working point at both ends of the bus bar through the voltage detection sensor, and take the detected voltage drop value as ΔP.

[0034] Step S102: preset voltage drop value: P0, compare the detected voltage drop value ΔP with the preset voltage drop value P0, and obtain the voltage drop difference P, namely: P=P0-ΔP; according to the voltage drop difference The size of the value P determines the heating state of the bus bar, that is, adjusts the PWM signal that needs to be output to the cooling fan, adds the difference P of the voltage drop to the PWM control circuit, and outputs the corresponding PWM signal to the cooling fan by adjusting the duty cycle. Fan control IC.

[0035] Step S103: the contr...

Embodiment 2

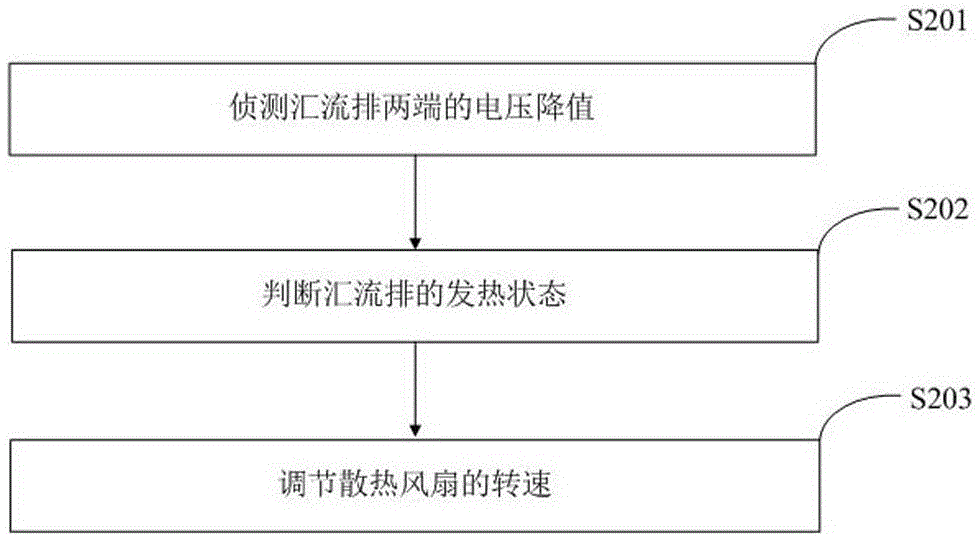

[0038] Such as figure 2 As shown, a method for regulating and controlling the heat dissipation of busbars comprises the following steps:

[0039] Step S201: Detect the voltage drop at both ends of the bus bar;

[0040] Step S202: judging the heating state of the bus bar;

[0041] Step S203: Adjust the rotation speed of the cooling fan.

Embodiment 3

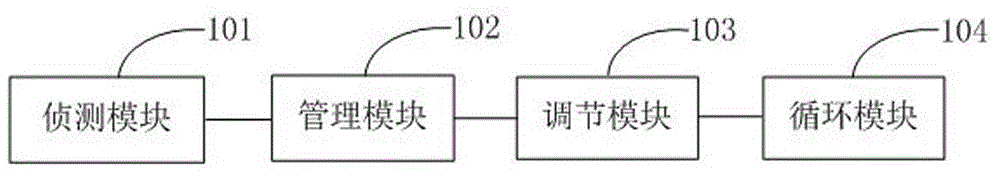

[0043] Such as image 3 As shown, a bus heat regulation device includes: a detection module 301, a management module 302, an adjustment module 303 and a circulation module 304, and the detection module 301 is sequentially connected to the management module 302, the adjustment module 303 and the circulation module 304 .

[0044] The detection module 301 is used to detect the voltage drop at both ends of the bus; the management module 302 is used to judge the heating state of the bus; the adjustment module 303 is used to adjust the speed of the cooling fan; the circulation module is used to adjust the heat dissipation After the speed of the fan is increased, the voltage drop value at both ends of the bus bar is continuously detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com