Planting body structure optimization method based on finite element model

An optimization method and implant technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as inability to adapt to threads, gingival collapse, poor bone density, etc., to increase implantation time and fix firmly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039]

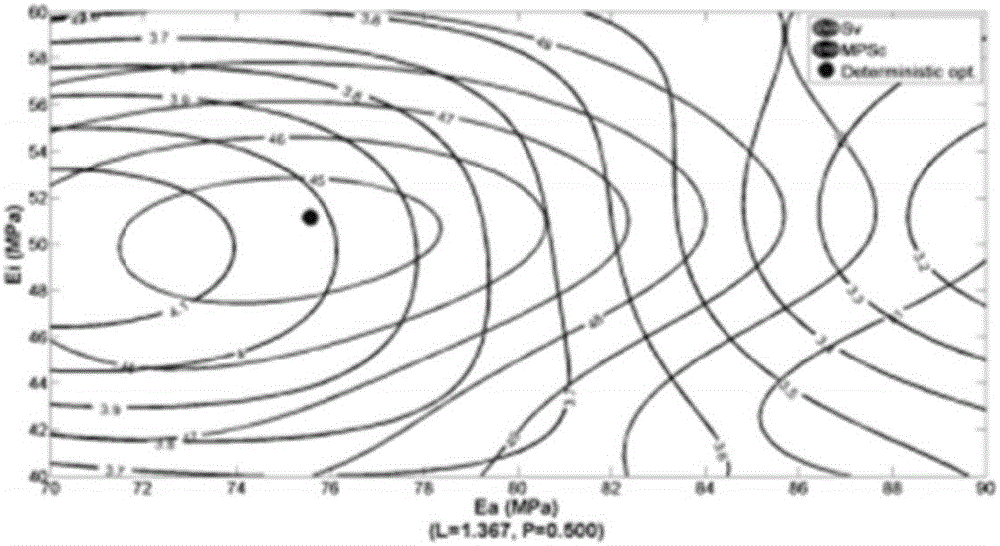

[0040] Design of Experiments (DOE) was performed using Latin Hypercube Design (LHD). First, a metamodel is created with sample point definitions. The sampling points are evenly distributed in the design space using the Latin hypercube sampling method, maximizing the minimum distance between the experimental points. Use LHD as the sampling method and set multiple sampling points. A limited analysis of the sampled data is performed line by line. The genetic algorithm (GA) is used to find the optimal parameters of the SVR model to improve the prediction accuracy. The proposed analysis results are similar to those shown in the figure below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com