LED display screen control system

A technology of LED display screen and control system, which is applied in the direction of static indicators, instruments, etc., can solve problems such as unfavorable high-density small-pitch LED display design, difficulty in testing LED display screens, and failure to meet display effect requirements, etc., to achieve improved display effect, reduce the number of cable cores, and monitor stable and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

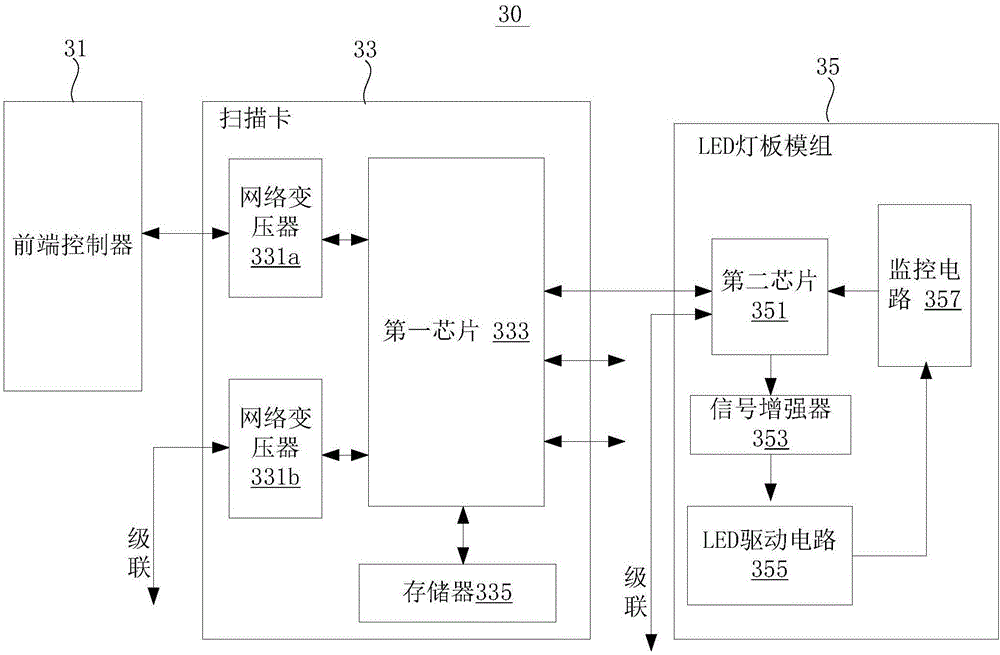

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

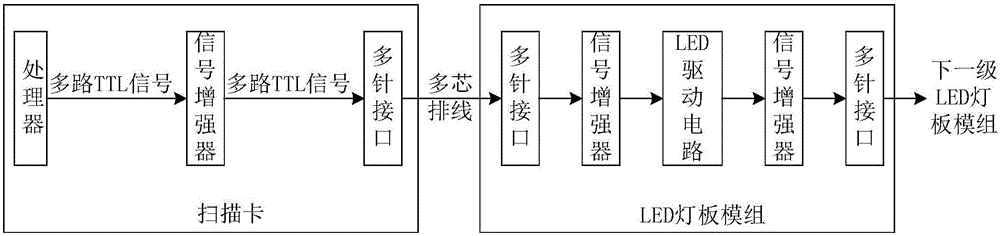

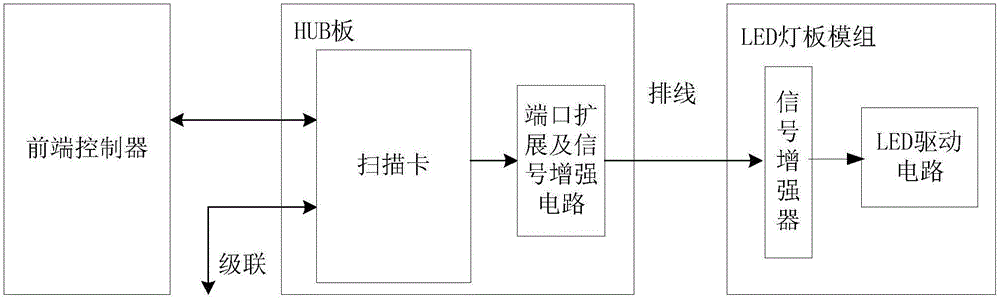

[0026] Specifically, the following embodiments of the present invention propose a new LED display control system solution, in order to solve the problems in the existing LED display control system, reduce the volume of the scanning card, support large load, and support high density and small spacing LED display body; at the same time solve the problem of poor display effect of the existing scanning card in the universal driver chip LED display body, improve the display effect of the screen body; and reduce the number of cables by using a new transmission method, Improve the stability and reliability of transmission, reduce EMI, and meet EMC requirements more easily.

[0027] see image 3 , which is a schematic diagram of an LED displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com