Black phosphorene film memory and preparation method thereof

A technology of black phosphorene and memory, applied in the field of memory, can solve the problems of insufficient research and development, and achieve the effect of fast conversion speed and stable reading and writing voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

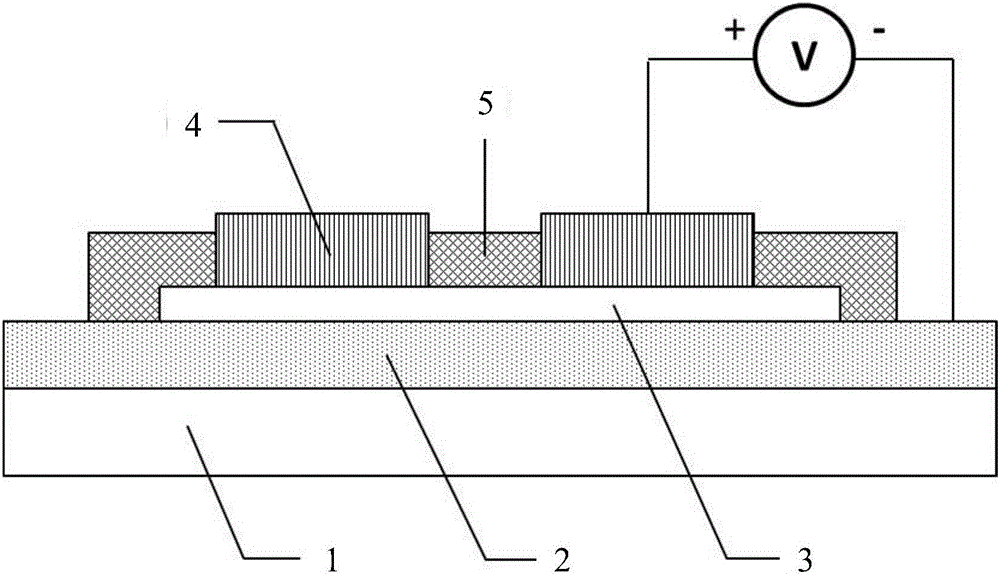

[0040] figure 2 The flow chart of preparing black phosphorene thin film memory through photolithographic patterning process for this embodiment includes:

[0041] (01)Al 2 o 3 substrate cleaning;

[0042] (02) Deposit Ni / Au bottom electrode layer;

[0043] (03) transfer the black phosphorene film to obtain the black phosphorene film layer;

[0044] (04) Forming a top electrode pattern through a photolithographic patterning process;

[0045] (05) depositing an Ag top electrode layer;

[0046] (06) Degumming and stripping technology to form a storage unit;

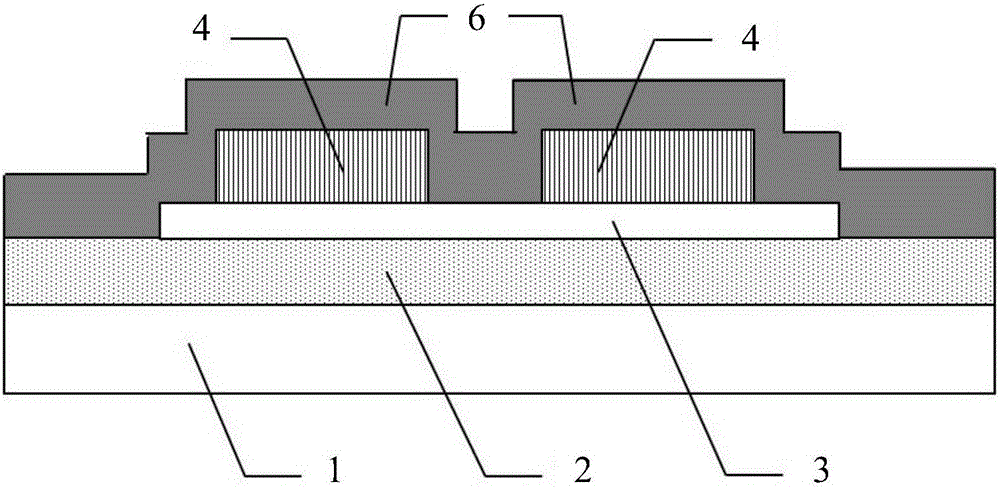

[0047] (07) Forming a cladding layer pattern by a photolithographic patterning process;

[0048] (08) Deposition of Al 2 o 3 cladding layer;

[0049] (09) Degum removal and peeling to form a coated storage unit.

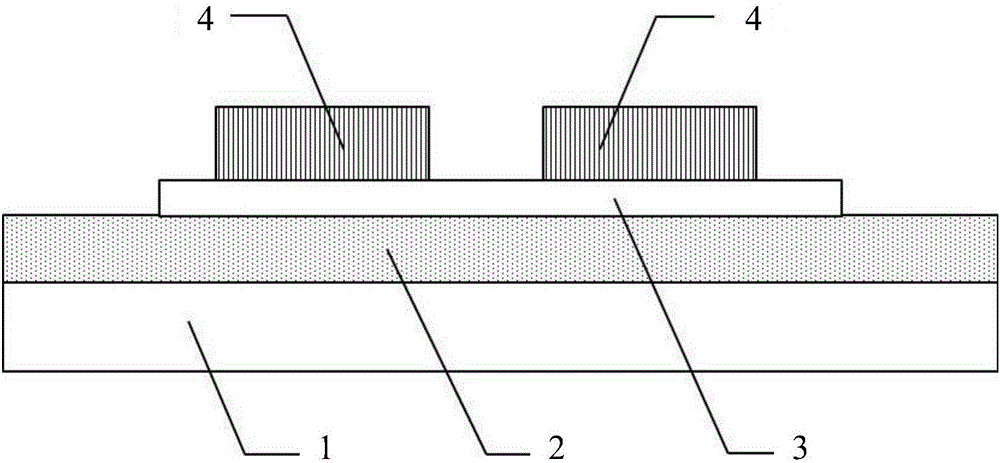

[0050] The basic structure of the black phosphorene thin film memory is obtained as figure 1 As shown, it includes a substrate 1 , a bottom electrode 2 , a black phosphorene thin film layer 3 and a top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com