Battery component for new energy vehicles

A technology for new energy vehicles and battery components, which is applied to battery pack parts, batteries, electrical components, etc. It can solve the problems of lowering the safety level of automobiles, battery fire extinguishing treatment, and difficult current cut-off, so as to increase the maximum usage, Meet the actual requirements and improve the effect of safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

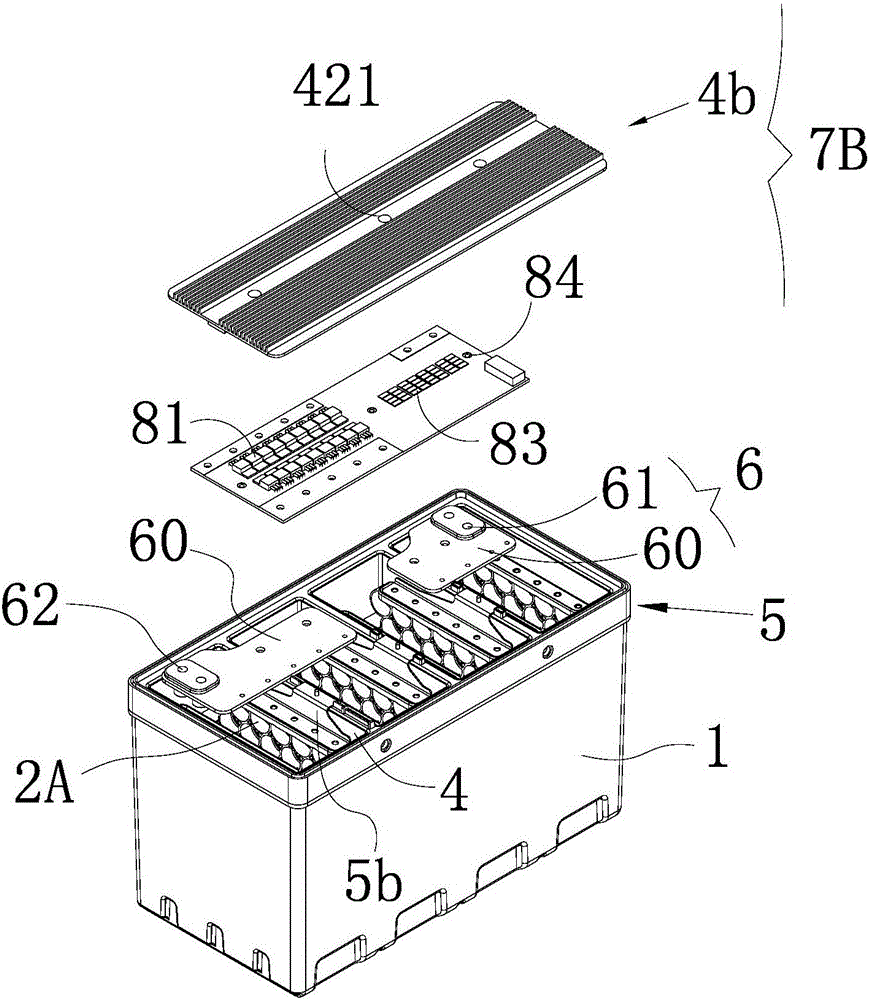

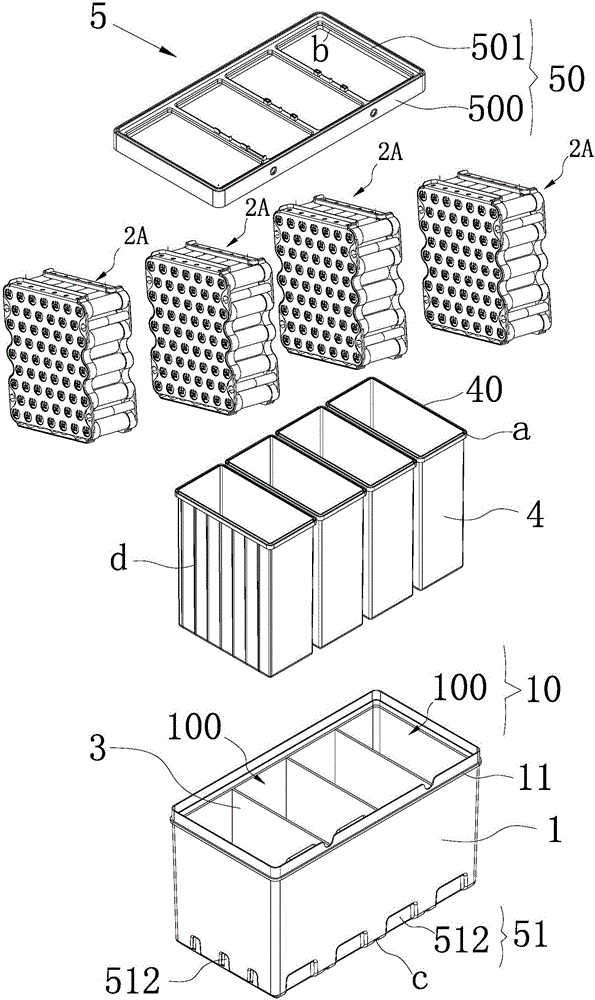

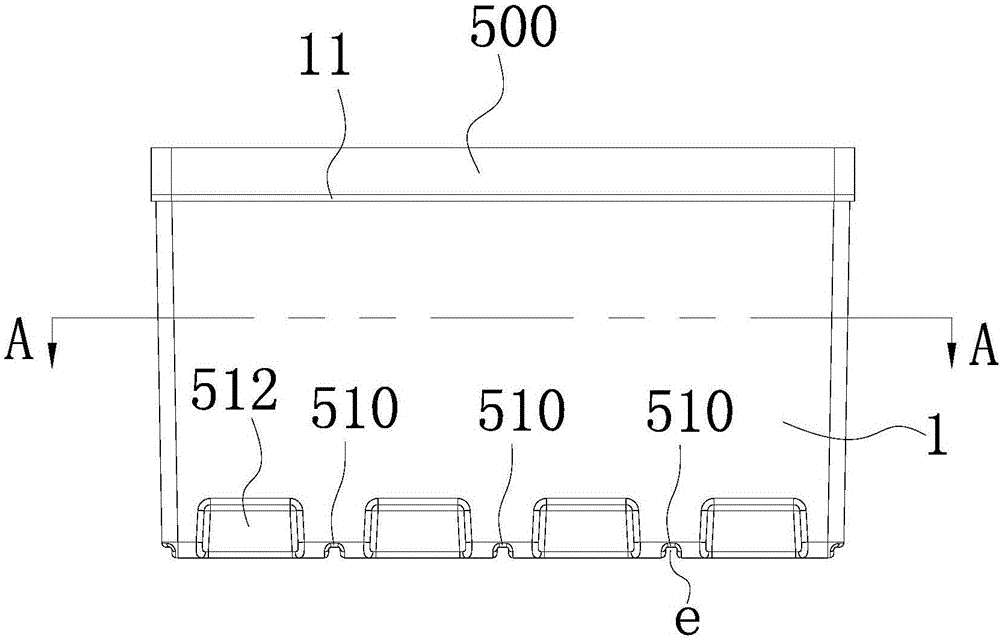

[0048] like Figure 1 to Figure 10 As shown, the battery assembly for new energy vehicles involved in this embodiment includes a housing 1, a plurality of battery cells 2A placed in the housing 1, and a cavity 10 arranged in the housing 1 to separate the cavity 10 into a plurality of The separator 3 of the sub-cavity 100, the liner 4 located in each sub-cavity, the positioning member 5 for positioning and connecting the multiple liners 4 with the housing 1, the battery cover 6, the heat dissipation assembly 7B, and the control circuit Board 8, in which a plurality of sub-cavities 100 are arranged in rows horizontally and vertically or distributed in rows longitudinally, wherein the battery cells 2A are correspondingly arranged in the inner tank 4, the inside of the separator 3 has accommodating spaces connected to each other, and the battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com