Multi-functional wire clamp device simple to assemble

A multi-purpose, wire clip technology, applied in the direction of the cable suspension device, etc., can solve the problems of expansion and contraction of mechanical fastener wire clips, easy structure loosening, high maintenance cost, simplify production and assembly difficulty, improve strength and safety. Stability, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

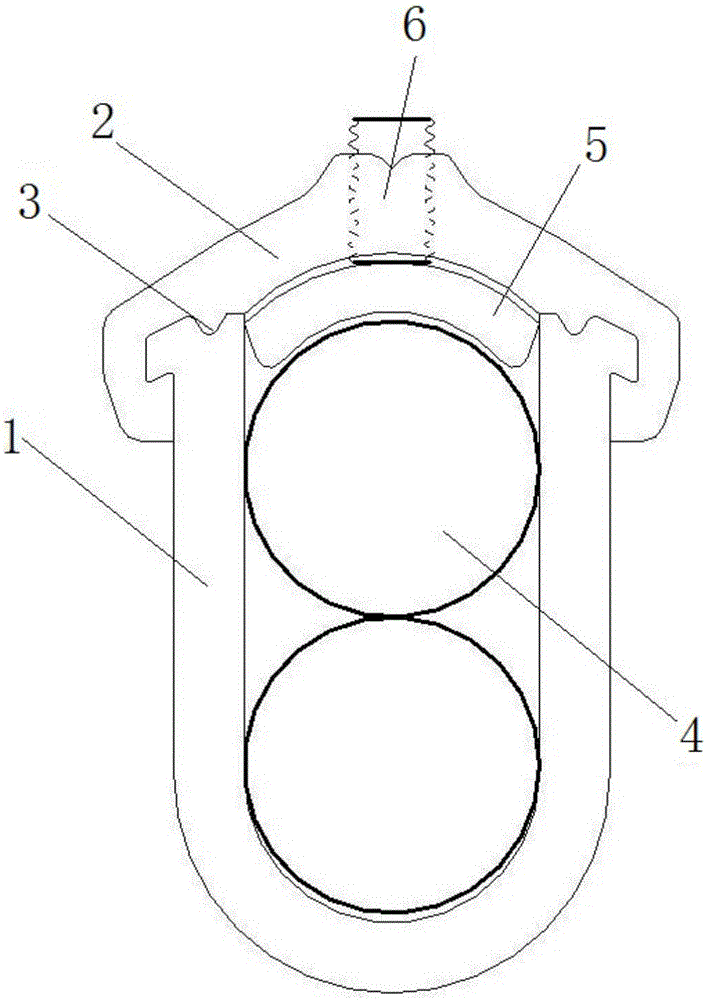

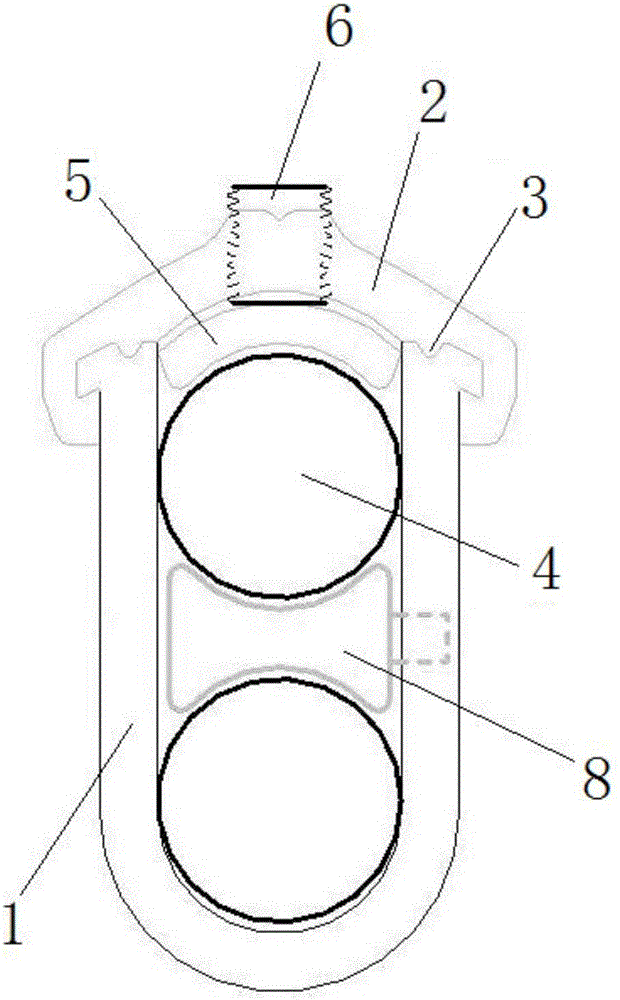

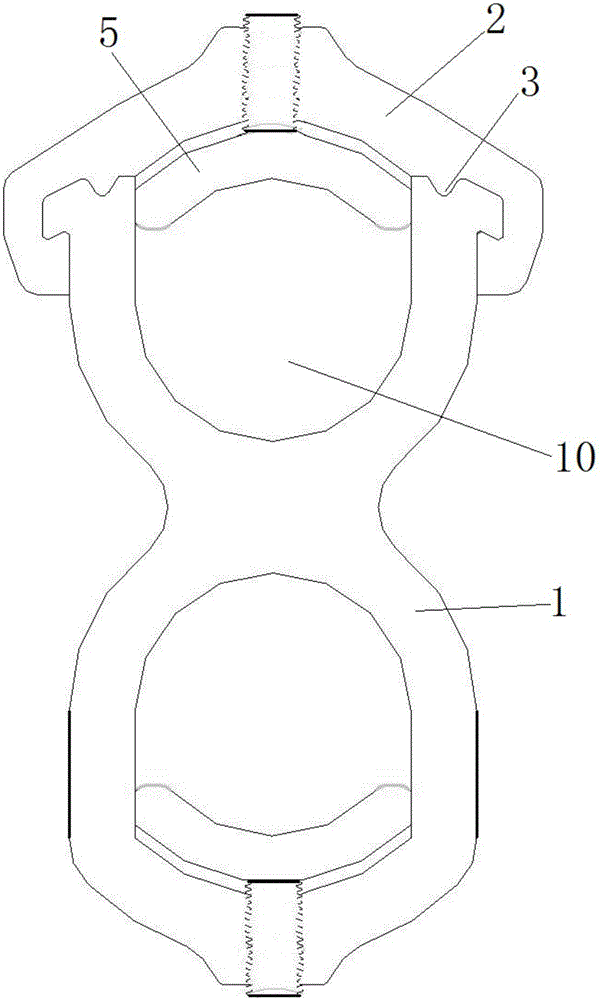

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Such as Figure 1-5 As shown, the present invention is realized in such a way that the multi-purpose wire clamp device with ease of assembly includes a wire clamp main housing 1 and a cover plate 2 that covers the wire clamp main housing 1, and its structural feature is that the cover plate The edge of 2 is engaged with the outer edge of the main housing 1 of the wire clamp, and a matching positioning structure 3 is provided on the corresponding position of the cover plate 2 and the main housing 1 of the wire clamp; the positioning structure 3 includes a wedge-shaped groove for positioning fit and Wedge block; the present invention uses the edge of the cover plate 2 to engage with the outer edge of the main case 1 of the wire clamp, so that the cover plate 2 can well cover the opening of the main case 1 of the wire clamp, thereby form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com