Dustproof motor

A motor and dust-proof technology, applied in the field of motors, can solve the problems of poor heat dissipation efficiency and affect the performance of the motor, so as to ensure the dustproof effect, improve the heat dissipation effect, and prevent the entry of impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

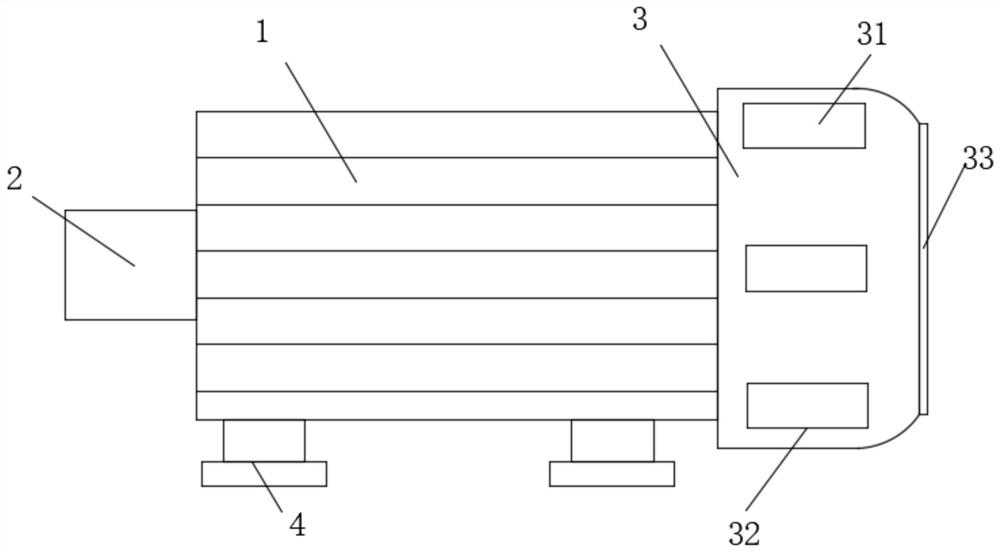

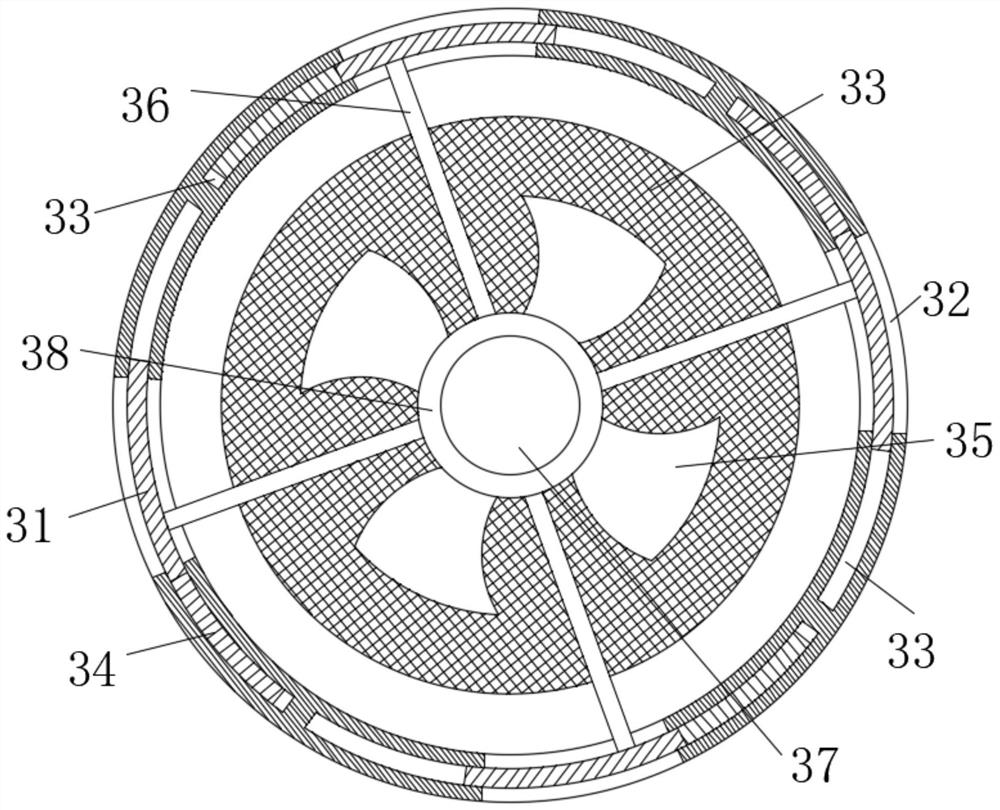

[0018] see Figure 1-2 , a dust-proof motor, comprising a body 1, one end of the body 1 is provided with an output shaft 2, and the other end of the body 1 is provided with a fan 35 for heat dissipation, and the body 1 outside the fan 35 is provided with a fixed connection The dust cover 3, the outer end of the dust cover 3 is provided with a heat dissipation net 33 for heat dissipation and ventilation, and the outer wall of the dust cover 3 is provided with a plurality of evenly distributed heat dissipation holes 32, located on the side of the heat dissipation holes 32 The dust cover 3 is provided with a first contraction groove, and the first contraction groove is provided with a sealing plate 31 that is slidably connected and used for sealing the cooling holes 32. The cover 3 is provided with a second contraction groove, and the second contraction groove is provided with a ventilation screen 34 which is slidably connected. The ventilation screen 34 is connected and fixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com