Hall sensor-based fault-tolerant control method of permanent magnet brushless motor

A technology of permanent magnet brushless motor and hall sensor, which is applied in motor control, motor generator control, electronic commutation motor control, etc. It can solve problems such as motor stall, motor sudden stagnation, and technical personnel's life safety threat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

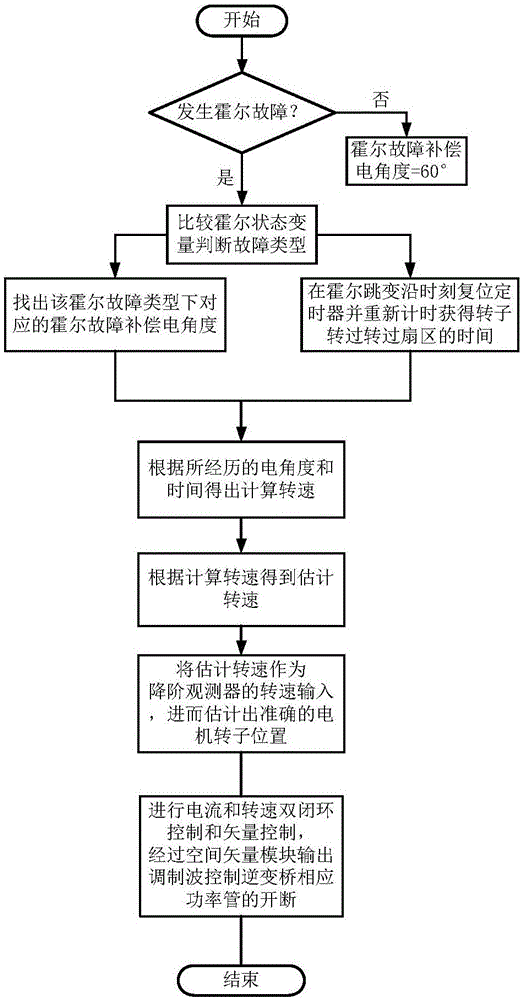

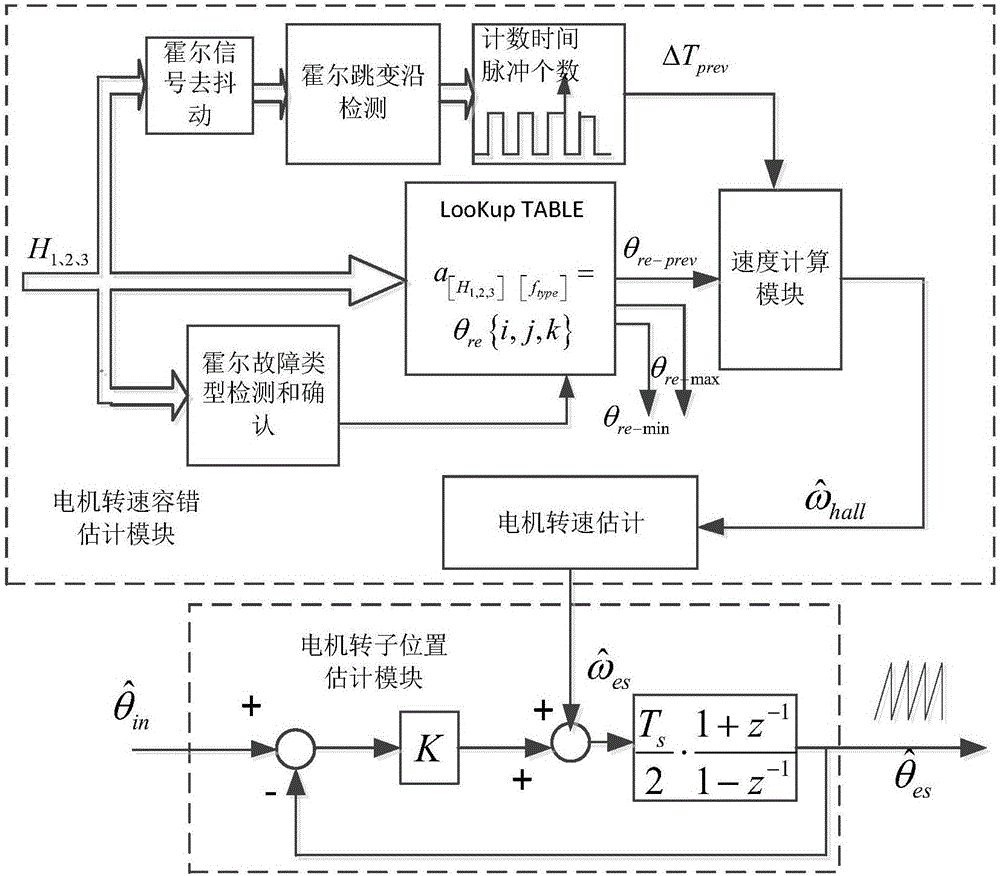

[0045] combine Figure 1~3 To illustrate this embodiment, the permanent magnet brushless motor mentioned in the present invention includes a permanent magnet brushless DC motor and a permanent magnet synchronous motor, and the permanent magnet synchronous motor is used to explain and illustrate the present invention in a specific embodiment. The flow chart of the fault-tolerant control method for the Hall sensor of the permanent magnet brushless motor in this embodiment, as shown in figure 1 As shown, the specific steps are as follows:

[0046] Step a. At any transition edge of the Hall position signal, determine whether a fault occurs according to the state of the transition edge. If there is no fault, the Hall fault compensation electrical angle θ re-prev Constantly 60°, if there is a failure, go to step b;

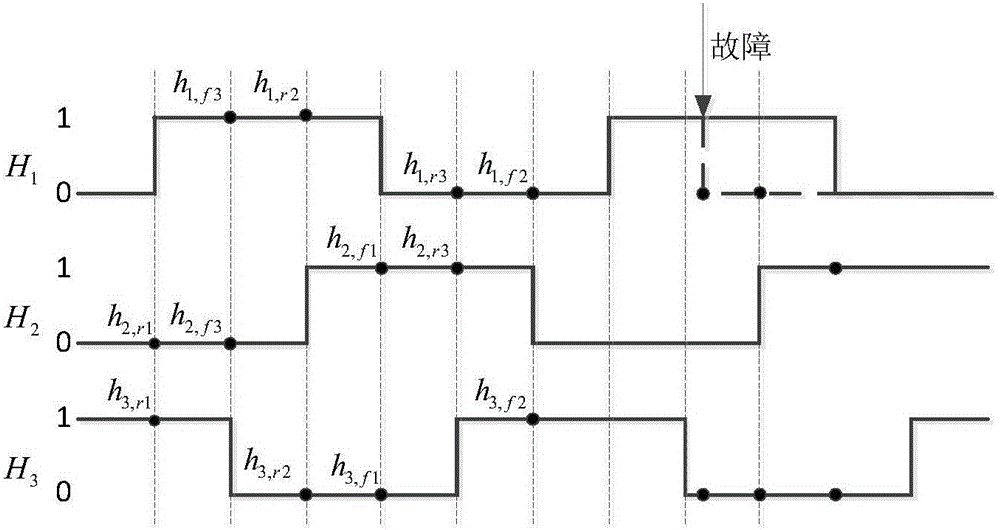

[0047]Step b. Collect the corresponding Hall state variable according to the type of Hall transition edge, and judge the unique Hall fault type according to the Hall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap