High-speed driving method for stepper motor

A technology of stepping motor and driving method, which is applied in the direction of motor generator control, electrical components, control system, etc., can solve problems such as lost steps, and achieve the effects of fast response speed, improved processing accuracy, and large control range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

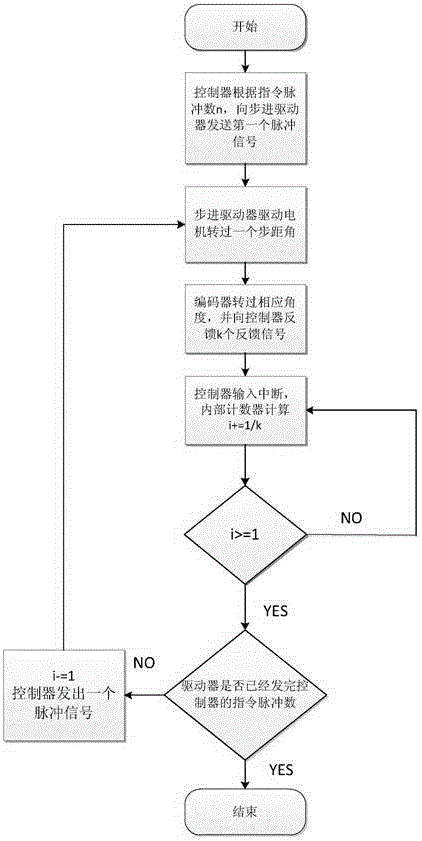

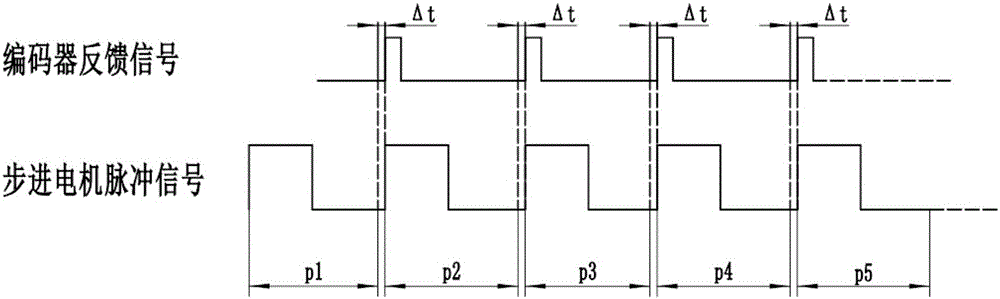

[0012] Due to the own characteristics of the stepping motor, it is determined that the pulse will be lost in the high-speed motion state, and sometimes the frequency is too high to cause the motor to block. Connect the incremental encoder and the stepping motor through a mechanical structure, and ensure that the stepping motor and the encoder rotate synchronously. When the motor rotates through a step angle, the corresponding encoder will feed back one or more signals to the controller. The controller uses the feedback signal as a trigger signal to control the drive motor to rotate through the next step angle. The feedback signal of the encoder is used as the pulse signal of the stepper driver to form a closed control to prevent loss of pulses. Due to the high speed of the encoder feedback signal, after the motor rotates through a step angle, it will receive several encoder feedback signals almost simultaneously to drive the next step angle.

[0013] A stepper motor driving m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com