Regeneration method for exhaust-gas aftertreatment device in engine-driven compressor, and engine-driven compressor provided with said aftertreatment device

An exhaust after-treatment, engine-driven technology, applied in exhaust devices, engine components, engine control and other directions, can solve problems such as increased exhaust resistance, inability to maintain active temperature, damage to the main body and filter element, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

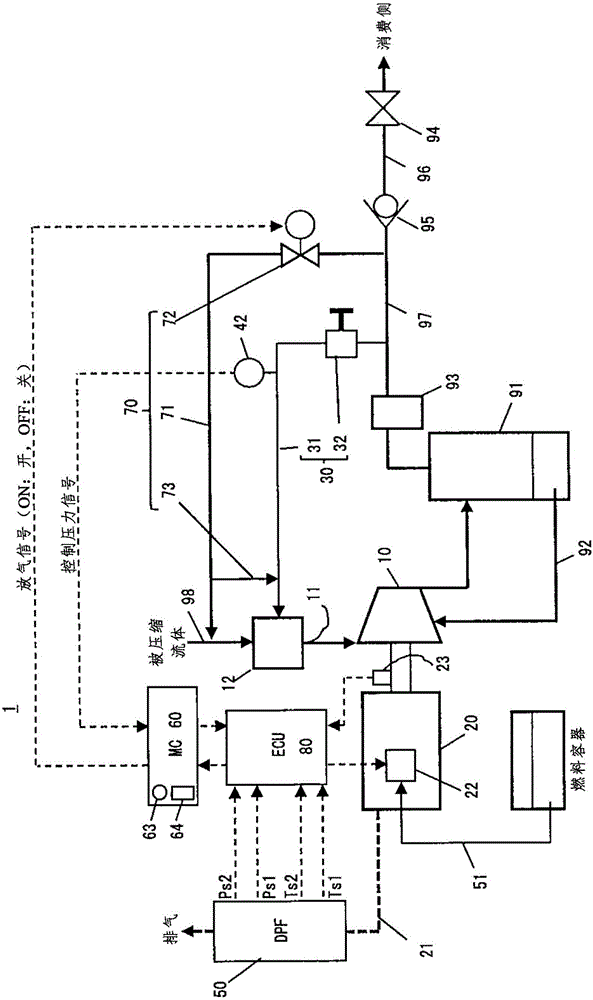

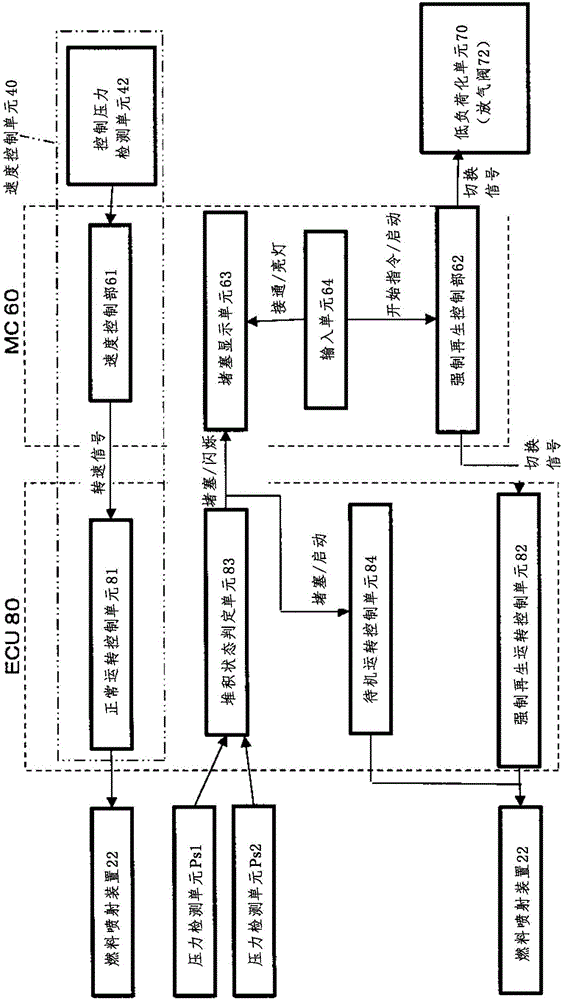

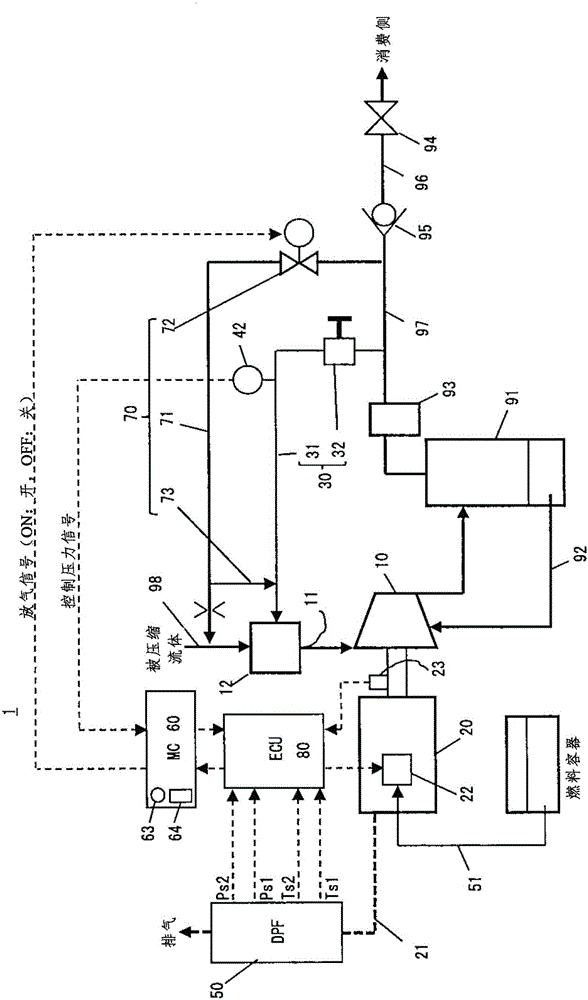

[0079] Hereinafter, the engine-driven compressor 1 of the present invention will be described with reference to the drawings.

[0080] [Constant load type forced regeneration]

[0081] In the forced regeneration method of the DPF performed in the present invention, "constant load type forced regeneration" performed in a state in which load fluctuations of the engine are excluded is adopted.

[0082] In the "constant load type forced regeneration", in order to obtain the optimum exhaust gas temperature / flow rate so that the oxidation catalyst is kept at the active temperature, a predetermined regeneration speed is set as the engine speed at the time of forced regeneration, Also, the main injection amount of fuel for maintaining the regenerative rotational speed is set in advance, and the fuel injection amount of the additional injection for raising the temperature of the oxidation catalyst is also set in advance.

[0083] The constant load type forced regeneration adopted in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com