Double-piston positive-negative pressure pneumatic pump fixed axis swing prosthetic knee joint

A dual-piston, knee joint technology, applied in prosthesis, medical science, artificial legs, etc., can solve the problems of the total weight of the prosthesis assembly cannot be reduced, the air pressure system has a long stroke, and the walking ability is affected, so as to reduce the prosthetic assembly weight, Walking posture simulation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

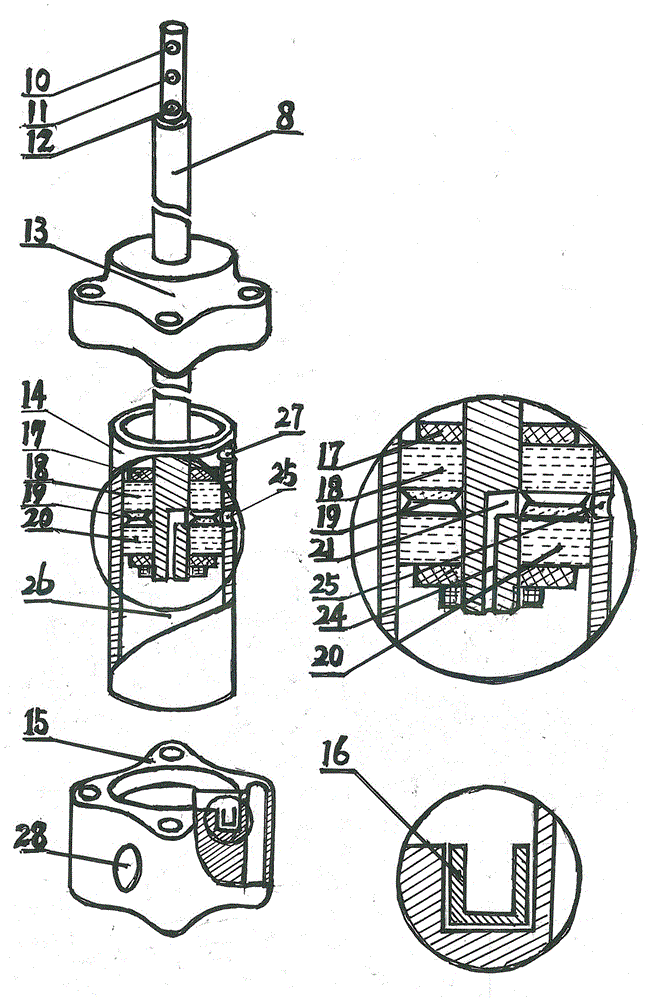

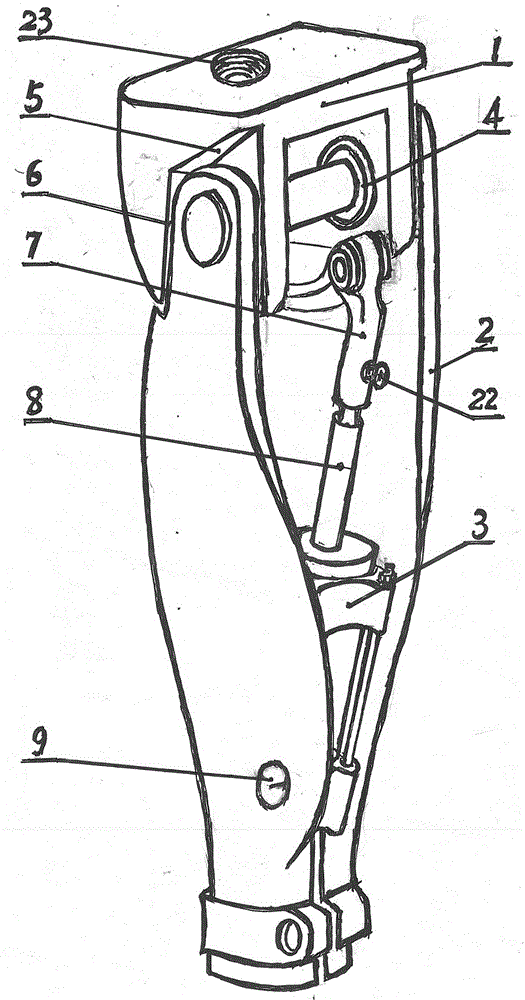

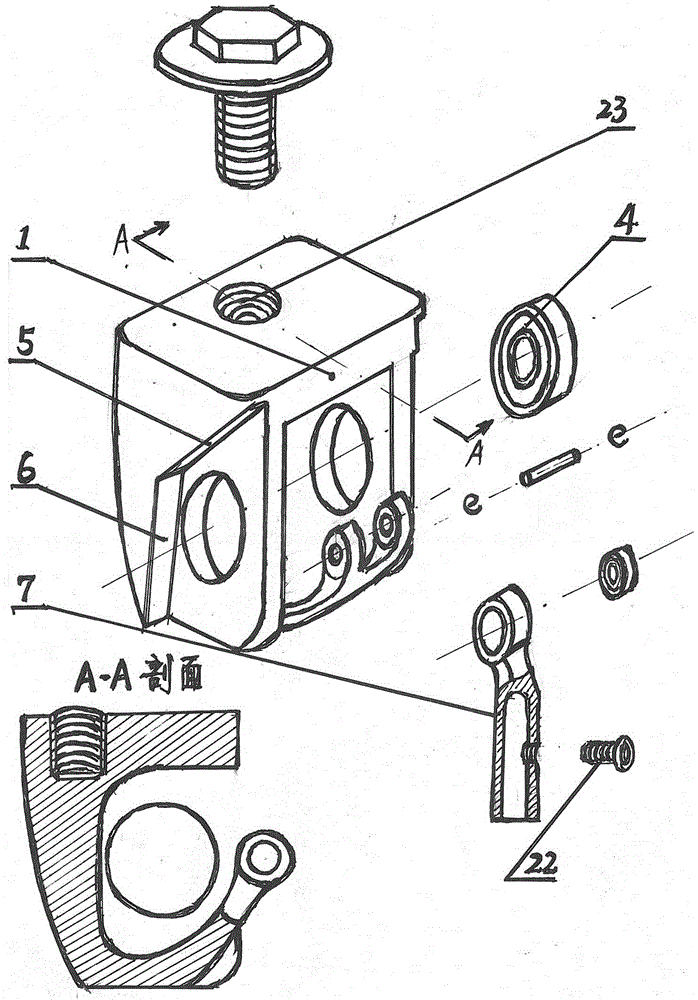

[0011] The maximum opening angle of the prosthetic knee joint is greater than 180 degrees and less than 185 degrees, and the specific angle can be determined according to actual requirements. Adjustment hole 10, adjustment hole 11, adjustment hole 12 are arranged on the moving shaft 8 of air pump 3, can form respectively link with the bolt 22 on the connecting rod 7 on the bracket seat 1. When the adjustment hole 10 is connected with the bolt 22, it is used by the relatively light person of body weight; when the adjustment hole 11 is connected with the bolt 22, it is used by the person of normal weight; Considering the air-tightness problem of air pressure pump 3 in practice, the idle travel problem of moving shaft 8 on the air pressure pump 3, the whole assembly weight problem, the cross-sectional size problem of piston 18 and piston 20 on the air pressure pump 3. The present invention takes the negative pressure generated by the air pump 3 as a buffer, and the residual limb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com