Machining tool

A technology for machining tools and tool heads, applied in the field of carbide machining tools, can solve the problems of inability to adjust the position, incomplete butt surface, etc., and achieve the effect of solving the incomplete butt surface and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

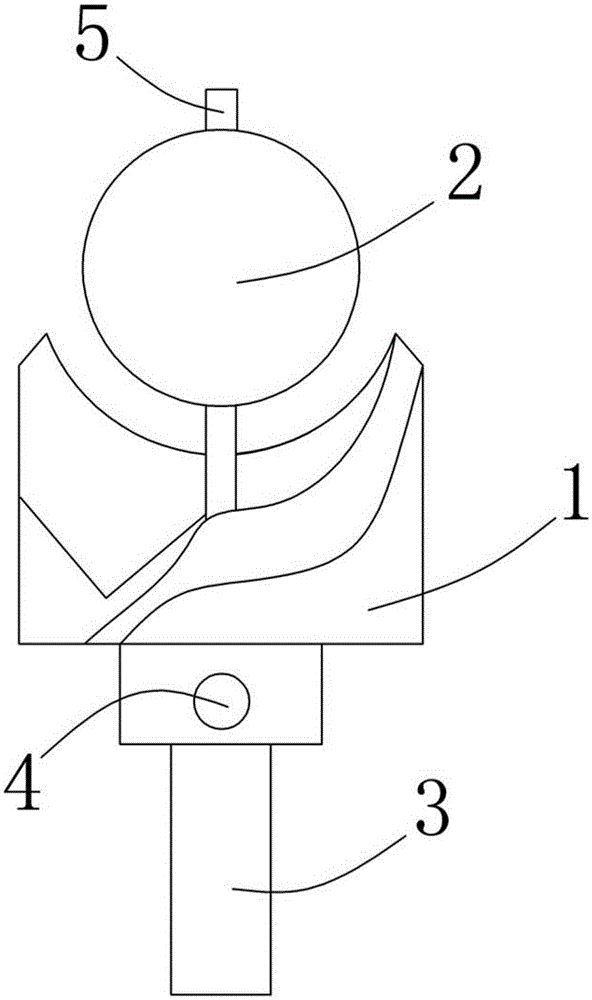

[0010] In order to make this Invention The existing technical means, creative features, goals and effects are easy to understand, and the following is combined with specific icon , to further elaborate on the invention .

[0011] see picture 1 , a machining tool structure picture , a machining tool , including a cutter head and a handle 3, the cutter head is detachably connected to the handle 3, the cutter head includes a drill bit 1 and a drill needle 5, and the drill needle 5 is fixed at the center of the drill bit 1. The upper end surface of the drill bit 1 is arc-shaped. The cutter head is made of hard alloy. The part where the drill needle is combined with the drill bit is provided with a boss, and the maximum diameter of the drill needle is 2-5cm.

[0012] Preferably, the cutter head is fixed on a steel base and connected to the knife handle 3 through the steel base, and the steel base is provided with two screw holes 4 through which the drill bit is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com