A kind of preparation method for sodium-ion battery cathode material sodium manganite

A sodium-ion battery and sodium manganite technology, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as low working voltage, low specific capacity of positive electrode materials, and lagging research progress in sodium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

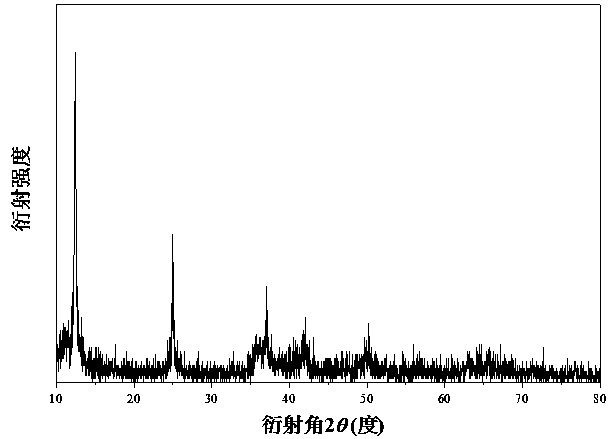

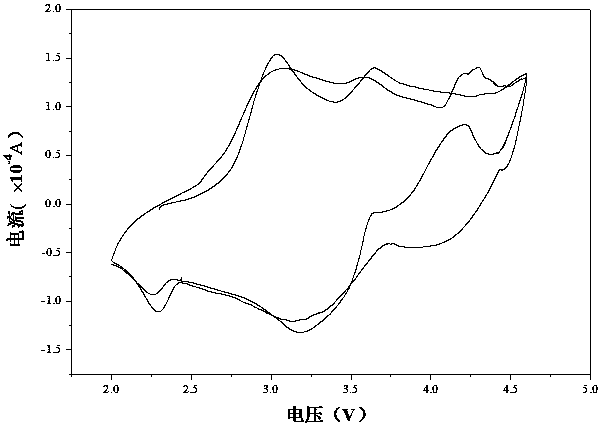

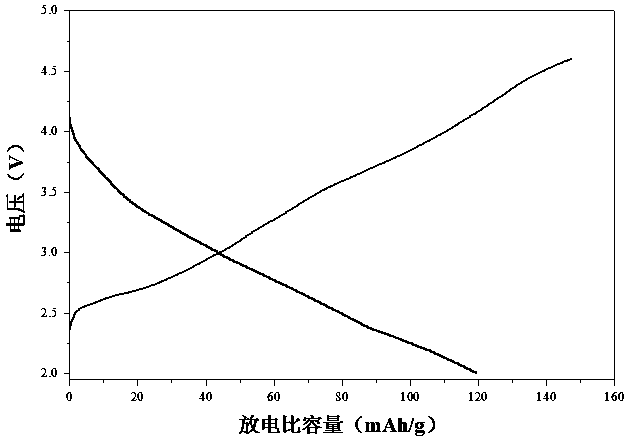

[0026] Add 0.015mol manganese dioxide and 0.037mol sodium hydroxide into the mortar respectively, grind and mix them evenly, then transfer the powder to a porcelain boat, and react in a tube furnace at 500°C for 10h under an argon atmosphere. Then naturally cool to room temperature, take out the product and wash it with water until the filtrate is neutral, then dry it in vacuum at 80°C, and grind the dried sample to obtain the product Na 2 MnO 3 . The X-ray powder diffraction pattern of the sample can be found in figure 1 , indicating that the resulting product is pure phase Na 2 MnO 3 , high crystallinity. The resulting product was used as the positive electrode material, and an experimental button-type sodium secondary battery was assembled in an argon-filled glove box. The charge-discharge cycle was carried out at a rate of 0.1C in the potential range of 2.0-4.6V. The specific capacity of the first discharge was 120mAh / g, showing excellent electrochemical performance. ...

Embodiment 2

[0028] Add 0.015 mol of manganese dioxide and 0.03 mol of sodium acetate into the mortar respectively, grind and mix evenly, then transfer the powder to a porcelain boat, react in a tube furnace at 450°C for 12 hours under a nitrogen atmosphere, and then naturally Cool to room temperature, take out the product and wash it with water until the filtrate is neutral, then dry it in vacuum at 110°C, and grind the dried sample to obtain the product Na 2 MnO 3 .

Embodiment 3

[0030] Add 0.015 mol of manganese dioxide and 0.03 mol of sodium nitrate into the mortar respectively, grind and mix evenly, then transfer the powder to a porcelain boat, react in a tube furnace at 600°C for 8 hours under a nitrogen atmosphere, and then naturally Cool to room temperature, take out the product and wash it with water until the filtrate is neutral, then vacuum-dry at 70°C, grind the dried sample to obtain the product Na 2 MnO 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com