Grouting sleeve for steel bar connection

A technology for grouting sleeves and steel bars, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of long formulation adjustment process, high price, and many materials used in products, and achieves good shear and compression resistance. The effect of high production waste and convenient processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

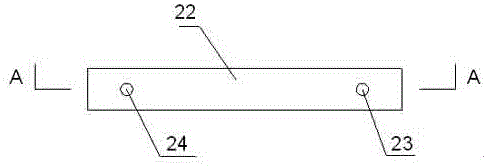

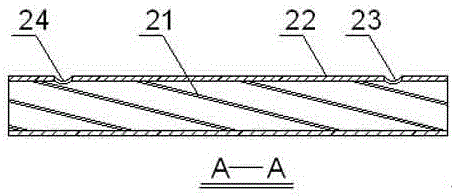

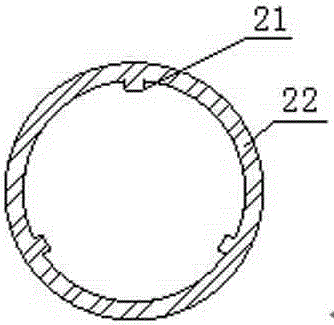

[0032] Such as Figures 1 to 4 As shown, a grouting sleeve for steel bar connection includes a sleeve body 22. One end of the sleeve body 22 is provided with a grouting port 23, and the other end is provided with a grouting port 24. The sleeve body 22 is made of seamless steel pipe, and The inner wall of the sleeve body 22 is provided with two or more protruding male riflings 21 , thereby forming concave female riflings, and the distance between adjacent male riflings 21 is equal.

[0033] In this embodiment, the two ends of the sleeve body 22 are provided with elastic rubber sealing rings 25 to form a fully grouted sleeve. The two ends are respectively inserted with reinforcing bars 26, and are solidified and fixed by the grouting material 27.

[0034] In this embodiment, the rifling provided on the inner wall of the sleeve body 21 is an equidistant rifling. In order to further improve the tensile, shear and compression resistance of the sleeve, progressive rifling or mixed ...

Embodiment 2

[0036] Such as Figures 5 to 7 As shown, a grouting sleeve for steel bar connection includes a sleeve body 2, one end of the sleeve body 2 is provided with a grouting port 3, and the other end is provided with a grouting port 4, the sleeve body 2 is made of seamless steel pipe, and The inner wall of the sleeve body 2 is provided with two or more protruding male riflings 1 , thereby forming concave female riflings, and the distance between adjacent male riflings 1 is equal.

[0037] In this embodiment, one end of the sleeve body 2 is provided with a steel bar connecting portion, and the steel bar connecting portion is a constricted end 5, and the inner wall of the constricted end 5 is provided with threads 6 to form a semi-grouting sleeve. The end provided with the connecting part of the reinforcing bar can be inserted through rotation to fix the reinforcing bar 7 at this end, and the other end can be directly inserted into the reinforcing bar 7, and the grouting material 8 is ...

Embodiment 3

[0039] Such as Figures 8 to 10 As shown, a grouting sleeve for steel bar connection includes a sleeve body 12, one end of the sleeve body 12 is provided with a grouting port 13, and the other end is provided with a grouting port 14, the sleeve body 12 is made of seamless steel pipe, and The inner wall of the sleeve body 12 is provided with two or more protruding male riflings 11 , thereby forming concave female riflings, and the distance between adjacent male riflings 11 is equal.

[0040] In this embodiment, one end of the sleeve body 12 is provided with a steel bar connection part, which is a steel pipe extension 15, and the length of the steel pipe extension 15 is 1 / 2 of the length of the sleeve body 12, forming a semi-grouting sleeve . The end with the steel pipe extension 15 is squeezed so that the steel pipe extension 15 fits closely with the steel bar 16 to achieve a fixed connection, and the other end can be directly inserted into the steel bar 16, and the grout 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com