Piston pump with outlet valve in the piston

A technology of piston pumps and outlet valves, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, and can solve problems such as gasification and precipitation of fuel, reduction of transmission power, and reduction of piston pump transmission power. , to achieve the effects of reduced suction negative pressure, reduced dead volume, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

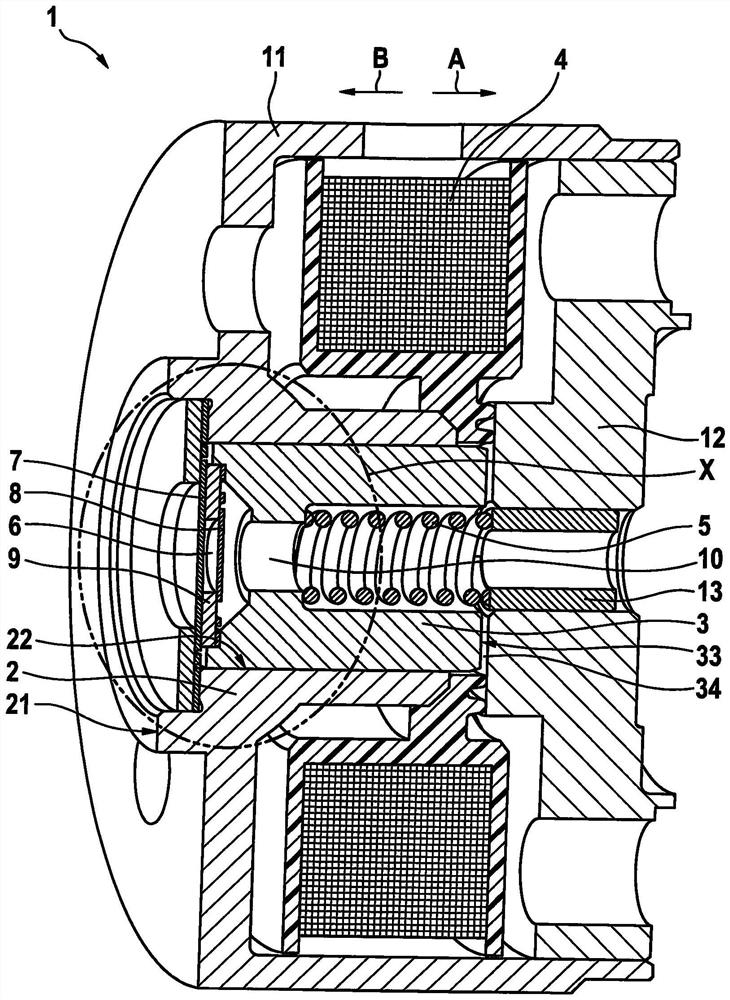

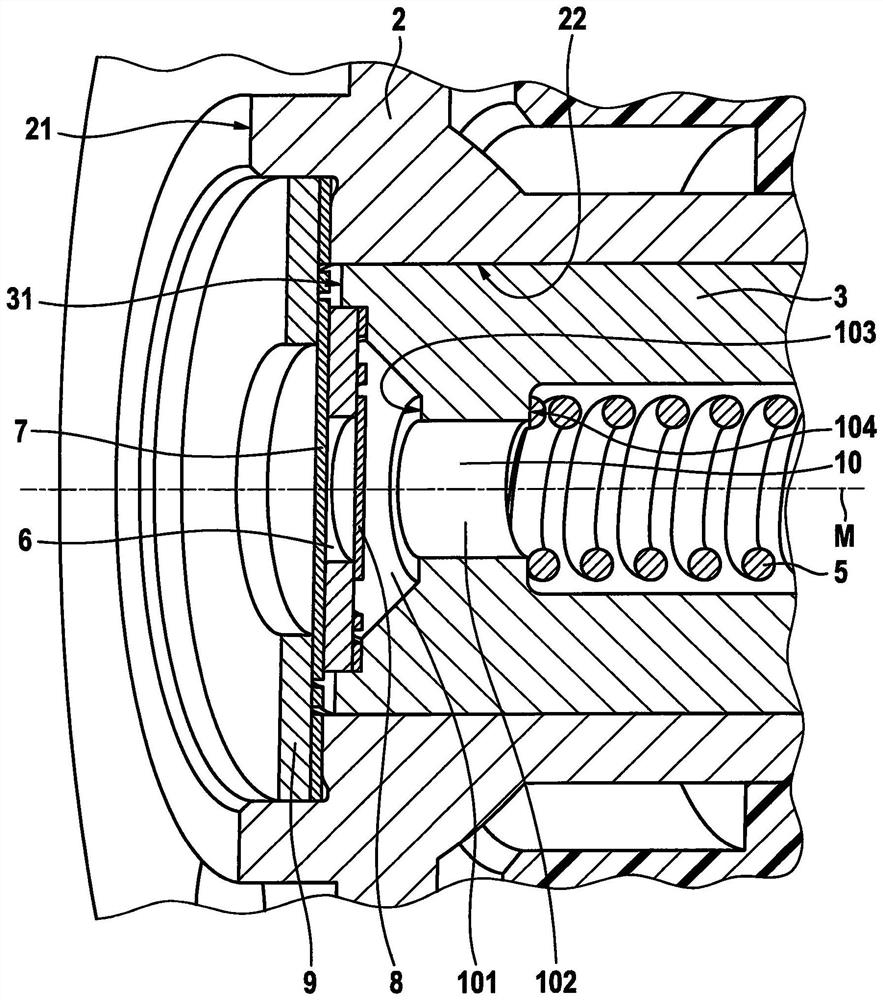

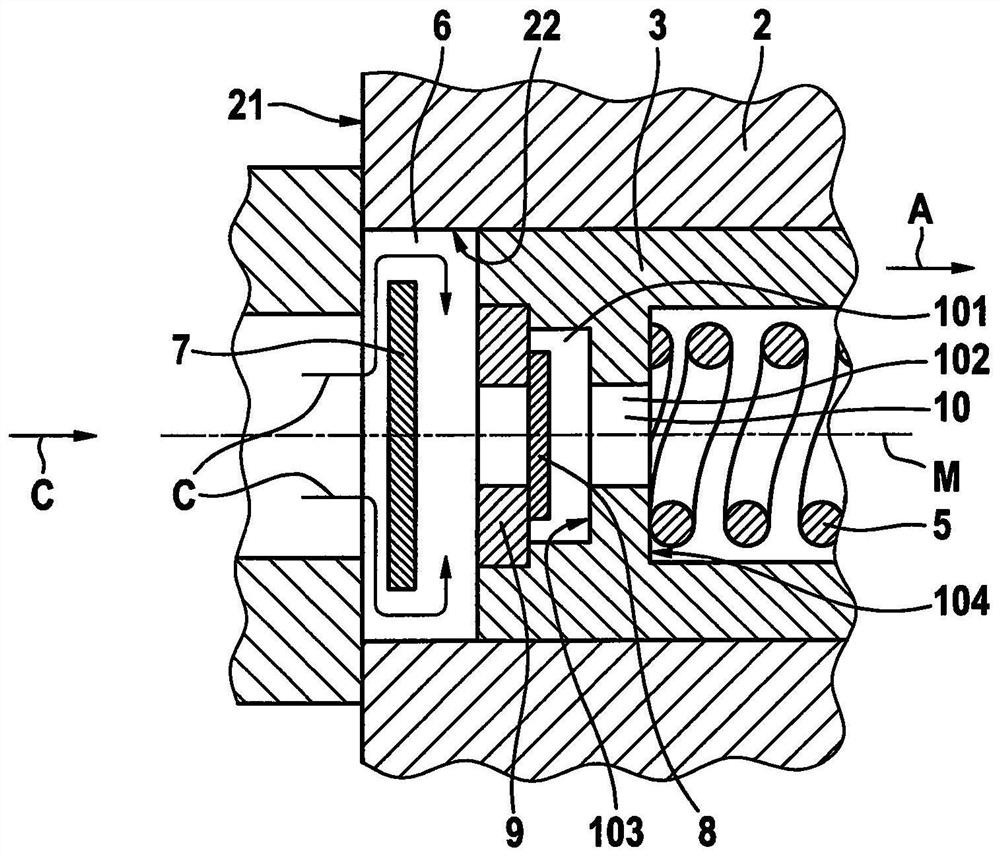

[0024] Refer below Figure 1a )and Figure 1b ) describes in detail the piston pump 1 according to a preferred embodiment of the present invention. exist Figure 1b ), in Figure 1a ) is shown enlarged.

[0025] Such as Figure 1a ) as can be seen, the piston pump 1 according to the invention is constructed in the form of an electromagnetic piston pump and correspondingly has a cylinder 2, a piston 3 arranged in the cylinder 2, as an actuator 4 to move in a first direction (arrow A) A solenoid operating the piston 3 and a spring acting as a return element 5 to move the piston 3 in the second direction (arrow B) up to its initial position. Furthermore, the fuel pump 1 according to the invention has a first inlet valve 7 , an outlet valve 8 and a compression chamber 6 . The components of the piston pump 1 are surrounded by a housing 11 and an armature plate 12 .

[0026] During the suction phase, the solenoid coil 4 is energized and the piston 3 is moved within the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com