A vibration exciter for an inertia cone crusher

A technology of cone crusher and vibrator, which is applied in the direction of vibrating fluid, grain processing, etc., can solve the problem that the crushing force of inertial cone crusher cannot be adjusted quickly, and achieve the effect of stable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

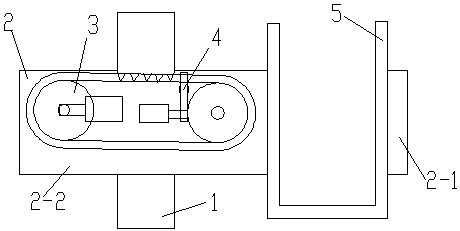

[0025] like figure 1 The vibrator of the inertia cone crusher shown, the vibrator of the inertia cone crusher includes an eccentric block 1 and an exciter 2, the eccentric block 1 is installed on the exciter 2, and the exciter 2. It is fixedly installed on the straight bushing 5. The excitation body 2 includes a sleeve 2-1 and a box body 2-2. The installation of the sleeve can be fastened and installed by means of bolts. The body 2-2 is provided with two gears 3, and the gears 3 are provided with a transmission chain; the shaft of the gear 3 is provided with a coupling, and the coupling is connected with the coupling on the motor a; The sleeve 2-1 is cylindrical, and the inner wall of the sleeve 2-1 is provided with fine teeth, and the fine teeth are perpendicular to the end face of the sleeve 2-1; a motor is installed in the box body 2-2 b, the shaft of the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com