Control system of inertial cone crusher

A technology of cone crusher and control system, which is applied in the direction of grain processing, etc., can solve the problems of high production cost, inconvenient adjustment of crushing force, low transmission efficiency of transmission parts, etc., and achieve the effect of strong adaptability and improved start-up ability

- Summary

- Abstract

- Description

- Claims

- Application Information

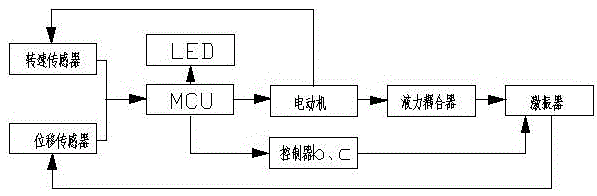

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

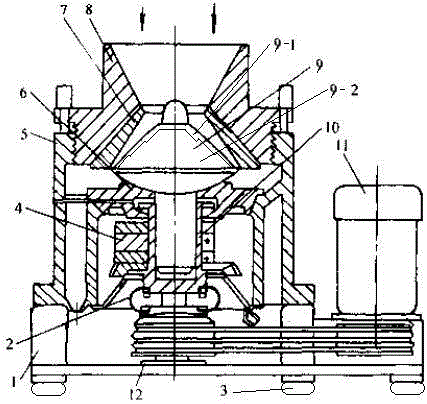

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] 1. If figure 1 An inertia cone crusher shown in the figure includes chassis 1, hydraulic coupler 2, vibration isolator 3, vibration exciter 4, support ring 5, spherical bearing 6, fixed cone 7, adjustment ring 8, moving cone 9, Cone cover 9-1, cone 9-2, straight bushing 10, motor 11, chain 12, the inertia cone crusher includes: chassis 1, vibration isolator 3, support ring 5, adjustment ring 8, the The vibration isolator 3 is provided with an underframe 1, the underframe 1 is equipped with a motor 11 and a supporting ring 5, an adjusting ring 8 is installed on the upper part of the supporting ring 5, and a bracket is arranged inside the supporting ring 5, so The support is provided with a main shaft, and the main shaft is inserted into the straight bush 10, and the vibration exciter 4 is installed on the outside of the straight bush 10, and the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com