Movable impact crushing station

An impact crushing and crushing system technology, applied in the field of corrosion-resistant steel bars, can solve the problems of poor site environment, unfavorable long-term operation of operators, and the inability to share interactively shared real-time working information of crushing station work information and safety information, so as to achieve a reasonable mechanism size , Submit the effect of enterprise profit and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

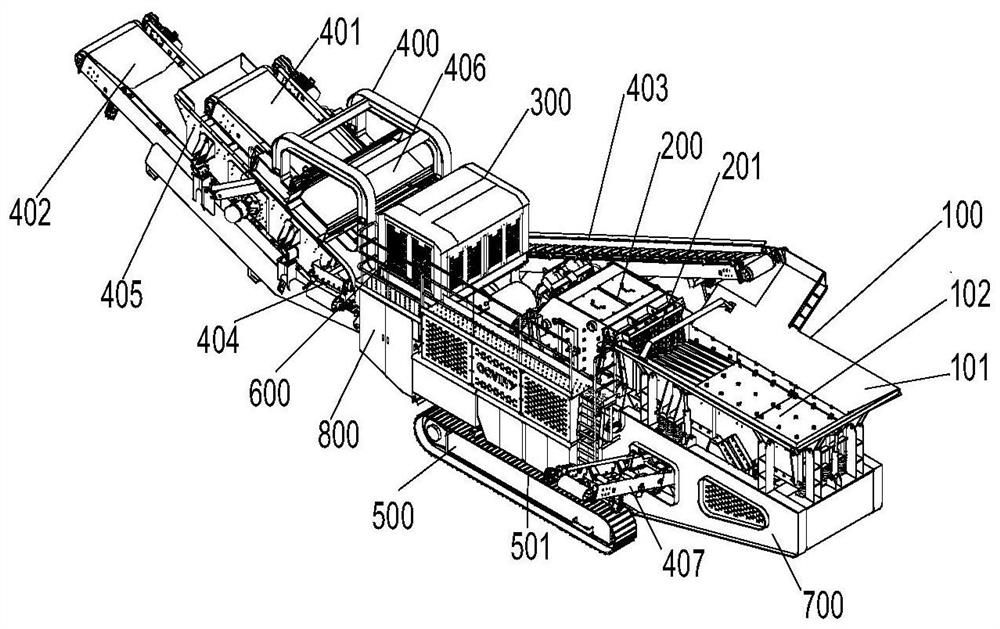

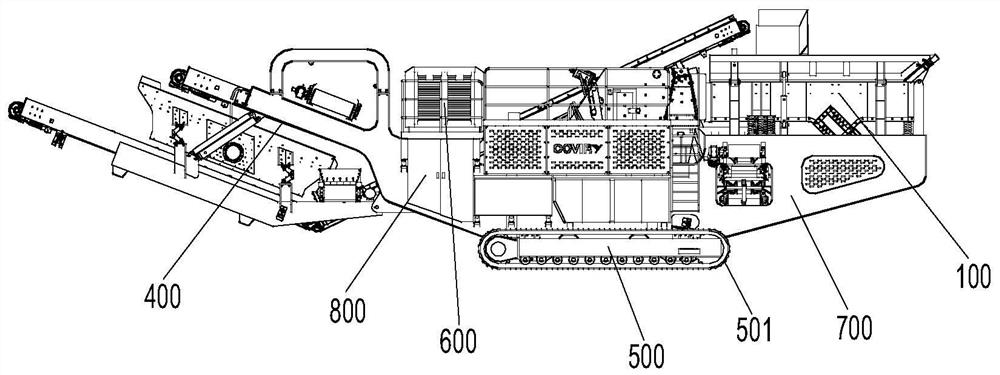

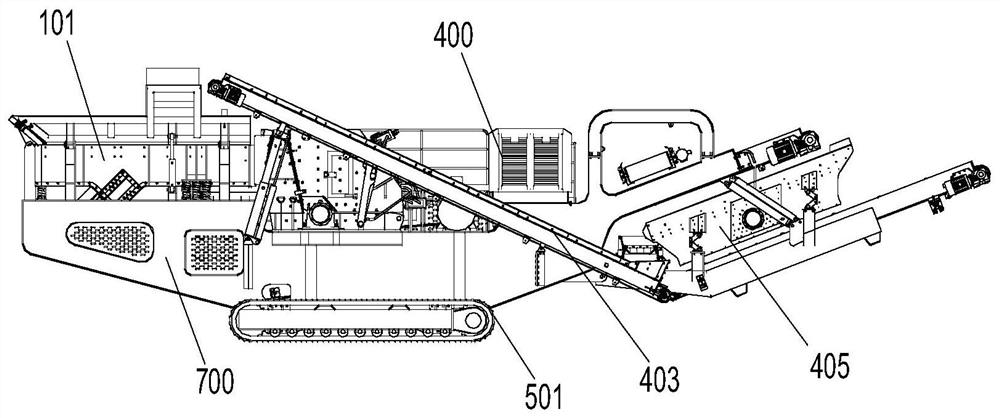

[0037] Example: such as Figure 1-9 , a mobile impact crushing station, the mobile impact crushing station includes a feeding system 100, a crushing system 200, a power system 300, a conveying system 400, a walking system 500, a hydraulic system 600, a base frame 700 and a control center system 800, the power Both the system 300 and the hydraulic system 600 are set in the power box, the base frame 700 is a ship-shaped structure, the walking system 500 includes a left crawler 501 and a right crawler 502, and the left crawler 501 and the right crawler 502 are located on the left and right sides of the bottom of the base frame 700, The power system 300 finally converts heat energy into hydraulic energy, and drives the left crawler belt 501 and right crawler belt 502 through the hydraulic system 600 to realize the walking operation;

[0038] The upper part of the base frame 700 is sequentially provided with a feeding system 100, a crushing system 200, a power system 300 and a conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com