Low-permeability water-bearing coal reservoir microwave steam explosion permeability-increasing adsorption-reducing method

A low-permeability, coal-reservoir technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve problems such as crack expansion, unfavorable new generation, reduced economic benefits, and reduced specific volume, etc., to achieve easy expansion and penetration , The migration channel is smooth and the system is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

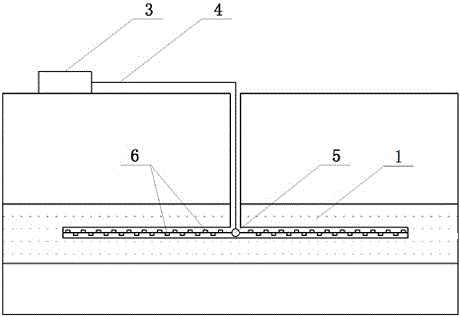

[0015] Such as figure 1 , figure 2 As shown, the microwave steam explosion anti-absorption method for low-permeability water-bearing coal reservoirs includes a microwave generator (3), a waveguide (4), a power divider (5), a port (6), a coal reservoir (1), Aqueous pores / cracks (2). The microwave generator (3) generates high-power microwaves on the ground, transmits them to the downhole power divider (5) through the waveguide (4), and then passes through the port (6) arranged in the coal reservoir (1) Shoot microwaves at coal rocks.

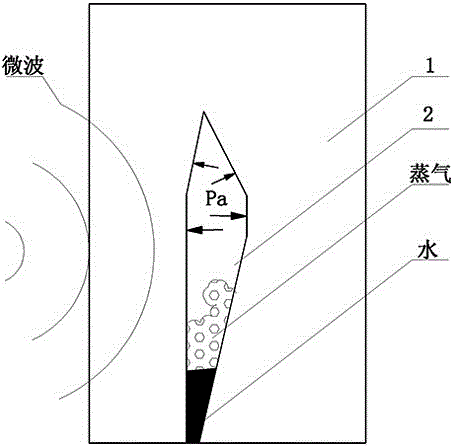

[0016] The water in the water-containing pores / cracks (2) in the coal reservoir (1) will evaporate instantly after being irradiate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com