Top anti-corrosion structure of chimney

A chimney and structural layer technology, applied in the field of chimneys, can solve problems such as corrosion of concrete substrates, and achieve the effects of preventing corrosion, ensuring corrosion resistance, and preventing aging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

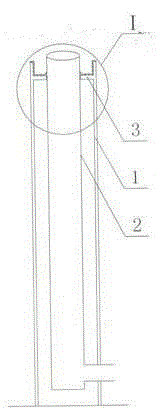

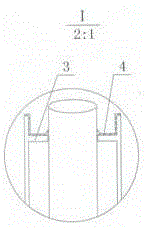

[0011] In the description of the drawings, the number 1 is a concrete outer tube, 2 is a glass fiber reinforced plastic inner tube, 3 is a concrete platform, and 4 is an anticorrosive structure layer.

[0012] The following further describes the top anti-corrosion structure of a chimney of the present invention with reference to the drawings and specific embodiments:

[0013] Such as Figure 1-2 As shown, in this embodiment, a top anti-corrosion structure of a chimney includes a concrete outer tube 1 and a glass fiber reinforced plastic inner tube 2. A concrete platform 3 is provided at the top of the concrete outer tube 1 and the glass fiber reinforced plastic inner tube 2. A skirt-shaped anti-corrosion structure layer 4 is provided on the glass fiber reinforced plastic inner tube 2 on the upper part of the concrete platform 3, and the skirt-shaped anti-corrosion structure layer 4 extends to the concrete platform 3, the concrete platform 3 and the concrete platform 3 The inner w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap