A deformation monitoring method for storage tanks with external floating roofs

A technology of deformation monitoring and external floating roof, which is applied in the direction of measuring devices, instruments, and optical devices, can solve problems such as high environmental stability requirements, large measurement errors, and detection efficiency and accuracy cannot be effectively guaranteed, so as to avoid Low work efficiency and consumption of manpower and material resources, avoid partial and one-sided effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

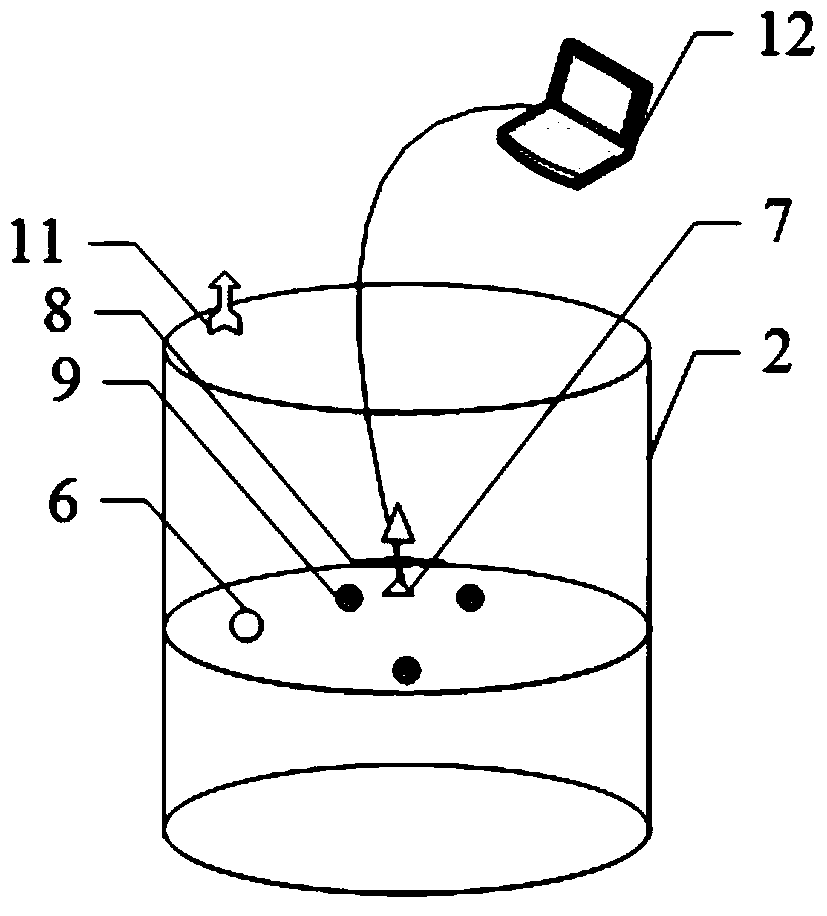

[0031] A method for monitoring the deformation of a group of external floating roof storage tanks of the present invention will be described in detail below through specific embodiments.

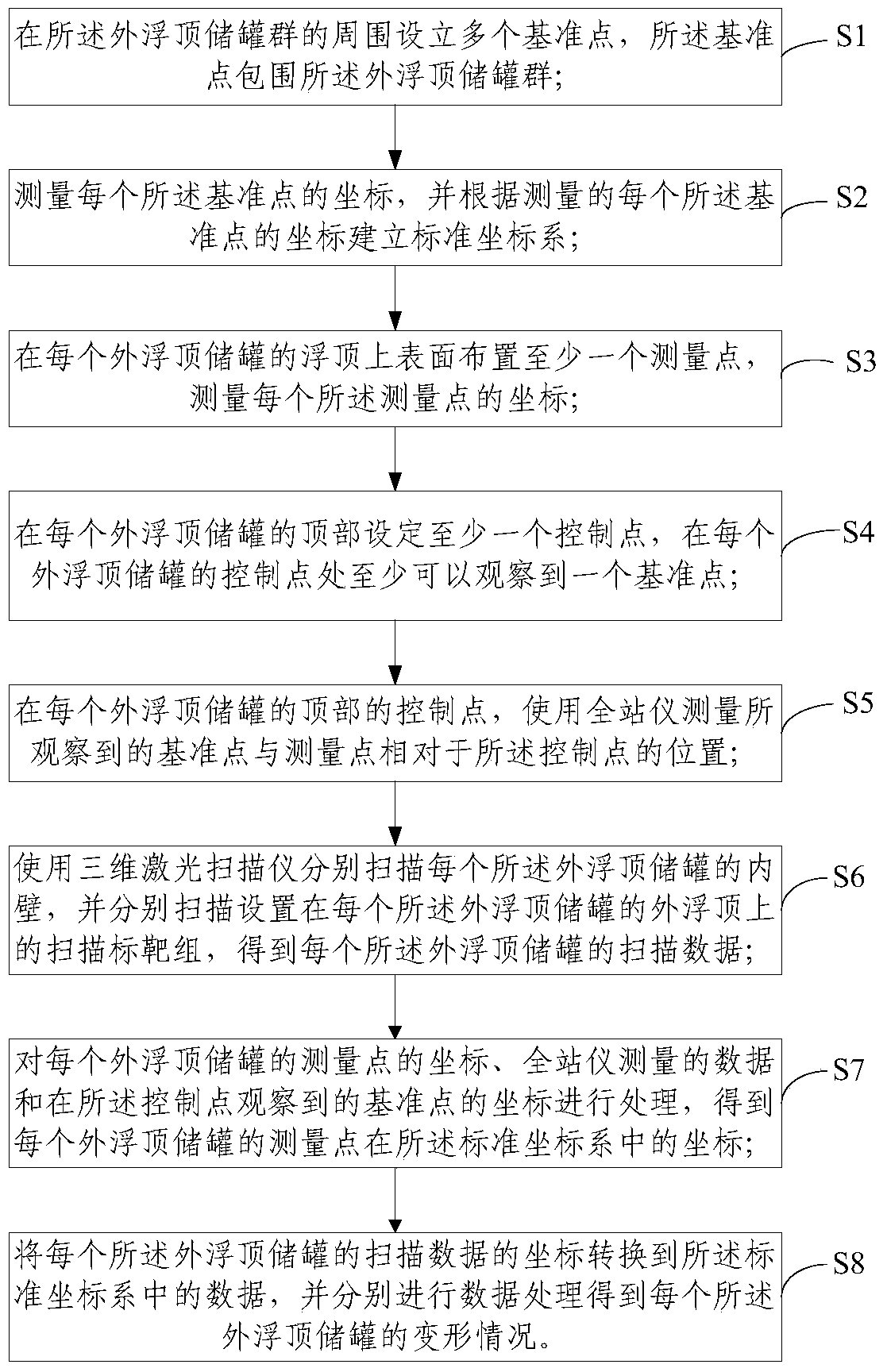

[0032] figure 1 It shows the flow chart of the deformation monitoring method of the outer floating roof storage tank group of the present invention.

[0033] In one embodiment of the present invention, a deformation monitoring method for external floating roof storage tanks specifically includes the following steps:

[0034] S1. Establishing multiple reference points around the group of outer floating roof storage tanks, where the reference points surround the group of outer floating roof storage tanks;

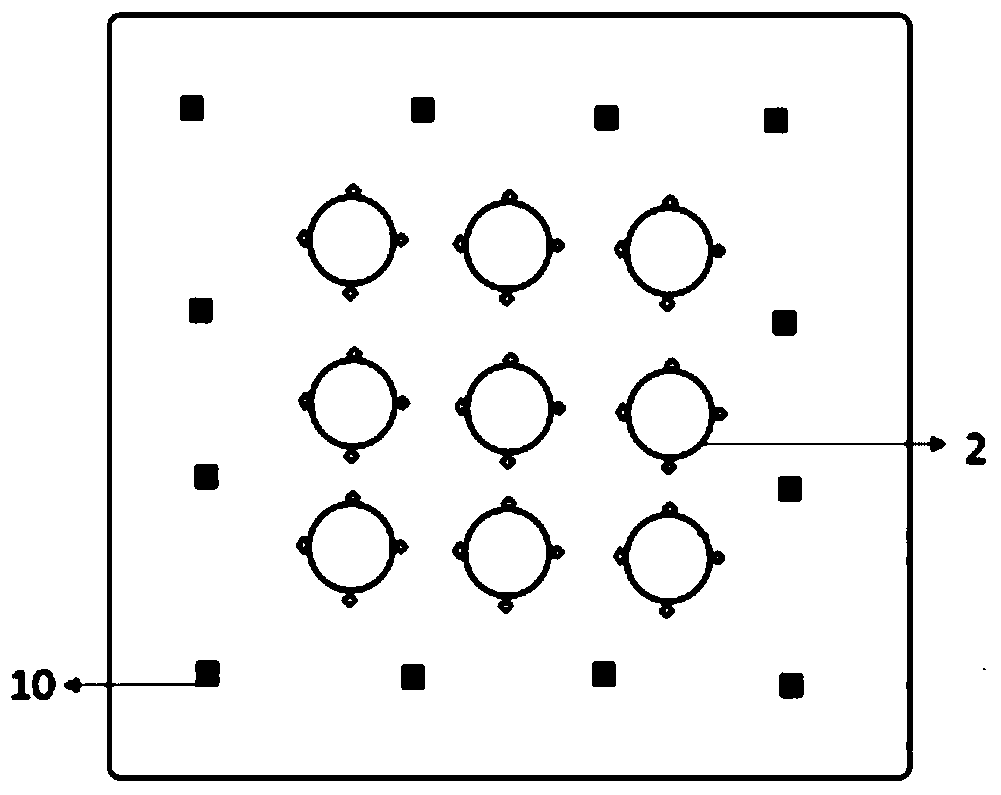

[0035] In the above embodiment, if figure 2 As shown, the number of reference points 10 set up around the outer floating roof storage tank group is set according to the quantity and floor area of the outer floating roof storage tanks 2 of the outer floating roof storage tank group.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com