A Coordinate Measuring System Used in Machining Blanking Process

A coordinate measuring system and machining technology, applied in measuring devices, instruments, etc., can solve the problems of heavy coordinate measuring machine, time-consuming and laborious handling of workpieces or components, and effective measurement of workpiece or component shapes. Portable, lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

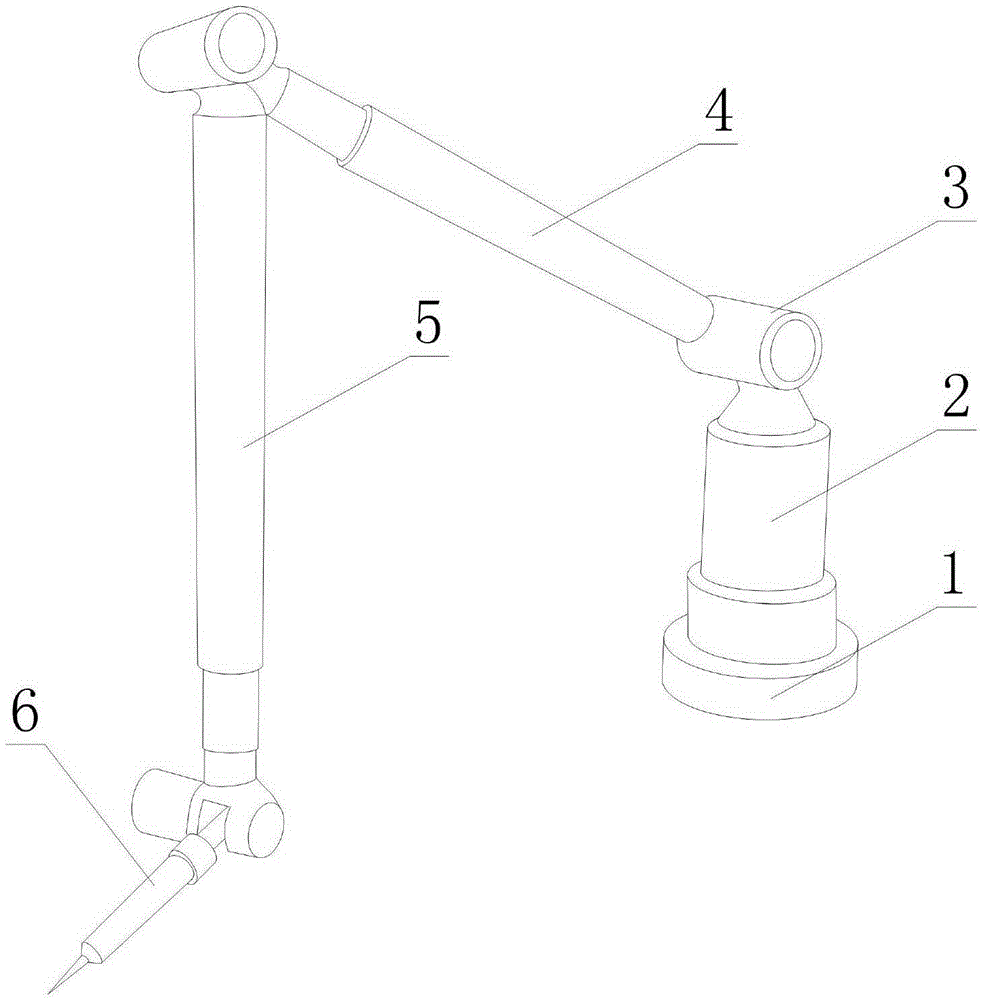

[0023] like figure 1 As shown, a coordinate measuring system for machining blanking process includes a measuring arm and a scanning head 6 fixed on the free end of the measuring arm, the measuring arm includes a first measuring arm 2, a second measuring arm 4 and The third measurement arm 5, any end of the first measurement arm 2 and any end of the second measurement arm 4 are hingedly connected through a hinge part 3, and the other end of the second measurement arm 4 and the third measurement arm 5 are hinged through a hinge The parts 3 are hingedly connected, the scanning head 6 is fixed on the free end of the third measuring arm 5, the free end of the first measuring arm 2 is also provided with a fixing seat 1, and the hinge axes of the two hinge parts 3 are parallel to each other;

[0024] The first measurement arm 2, the second measurement arm 4 and the third measurement arm 5 are all multi-section combined structures, and the multi-section combined structures all include...

Embodiment 2

[0030] This embodiment is further limited on the basis of Embodiment 1, such as figure 1 As shown, in order to facilitate the rotation of the scanning head 6 relative to the third measuring arm 5, so as to make the mechanism more dexterous to complete point and surface scanning, the third measuring arm 5 and the scanning head 6 pass through a hinge 3 Hinged connection, and the hinge axes of the three hinge parts 3 are parallel to each other.

[0031] As an implementation of the measuring arm with light weight, high specific strength and small thermal sensitivity coefficient, the material of both ends of the first measuring arm 2, the second measuring arm 4 and the third measuring arm 5 is made of titanium alloy , the parts between the two ends of the first measurement arm 2 , the second measurement arm 4 and the third measurement arm 5 are made of carbon fiber.

[0032] In order to have a high connection strength between the components of the device, and at the same time, it ...

Embodiment 3

[0034] This embodiment is further limited on the basis of any one of the solutions provided in the above embodiments. In order to facilitate the scanning efficiency of the device, the number or type of scanning heads 6 fixed on the free end of the third measurement arm 5 is more than one or more than one type. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com