Method for analyzing polycyclic aromatic hydrocarbon in soil by utilizing matrix solid phase dispersion extraction

A matrix solid-phase, polycyclic aromatic hydrocarbon technology, applied in the field of polycyclic aromatic hydrocarbons, can solve the problem of lack of selectivity of dispersants, achieve the effects of saving organic solvents, improving selectivity, and simplifying the analysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

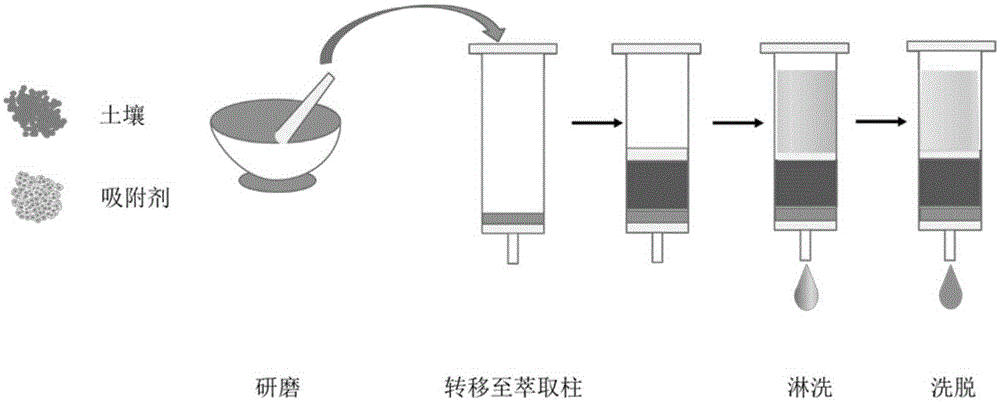

[0038] Example 1: (1) Preparation of phenyl-modified magnesium oxide microsphere adsorbent with high selectivity to polycyclic aromatic hydrocarbons; (2) The mass ratio of soil sample to step (1) adsorbent is 4:1 to 1 :4 Mix, transfer to a mortar and grind for 1-20min (such as image 3 (3) Put 10-100 mg of the adsorbent in step (1) into the extraction column as a purification layer; (4) transfer the homogeneous mixture obtained in step (2) to the extraction column in (3). Use solvent to rinse the extraction column, the eluent flows out of the extraction column by gravity to remove interfering substances. The volume of solvent used and the mass ratio of the homogeneous mixture are 10-20mL:1g; (5) continue the extraction column in step (4) Use the eluent for elution, and use the solvent volume to use the solvent volume and the mass ratio of the homogeneous mixture in the extraction column to be 10-20mL:1g; (6) Put the eluent in (5) at 30-40℃ Nitrogen is concentrated to near dryne...

Example Embodiment

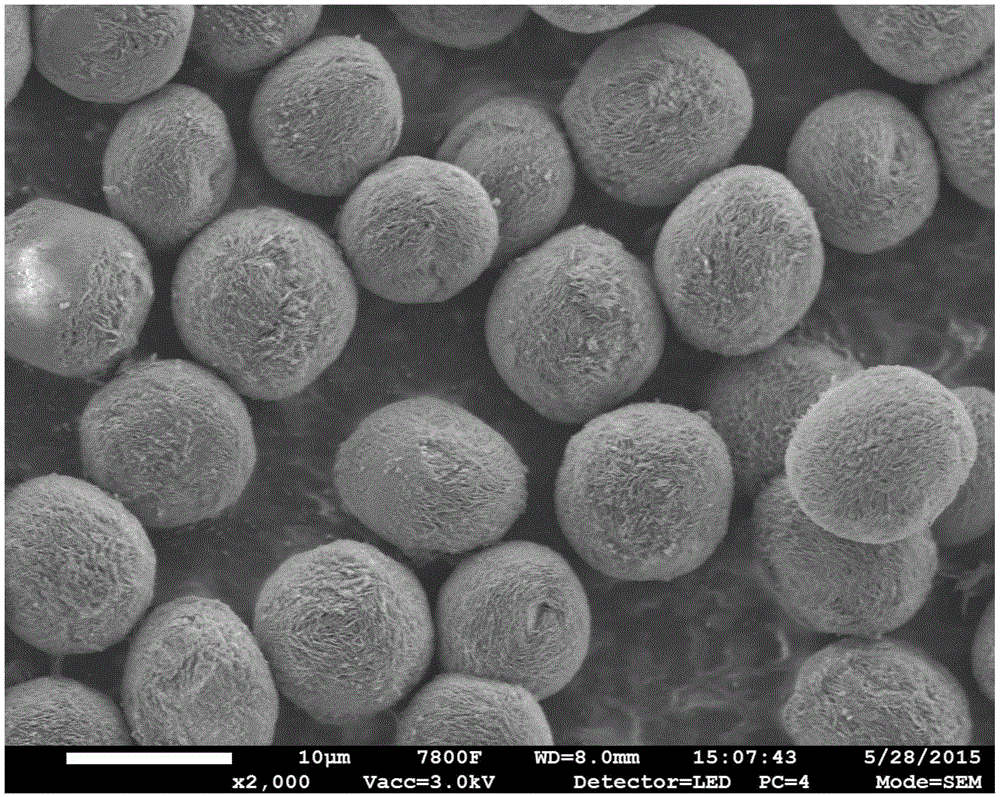

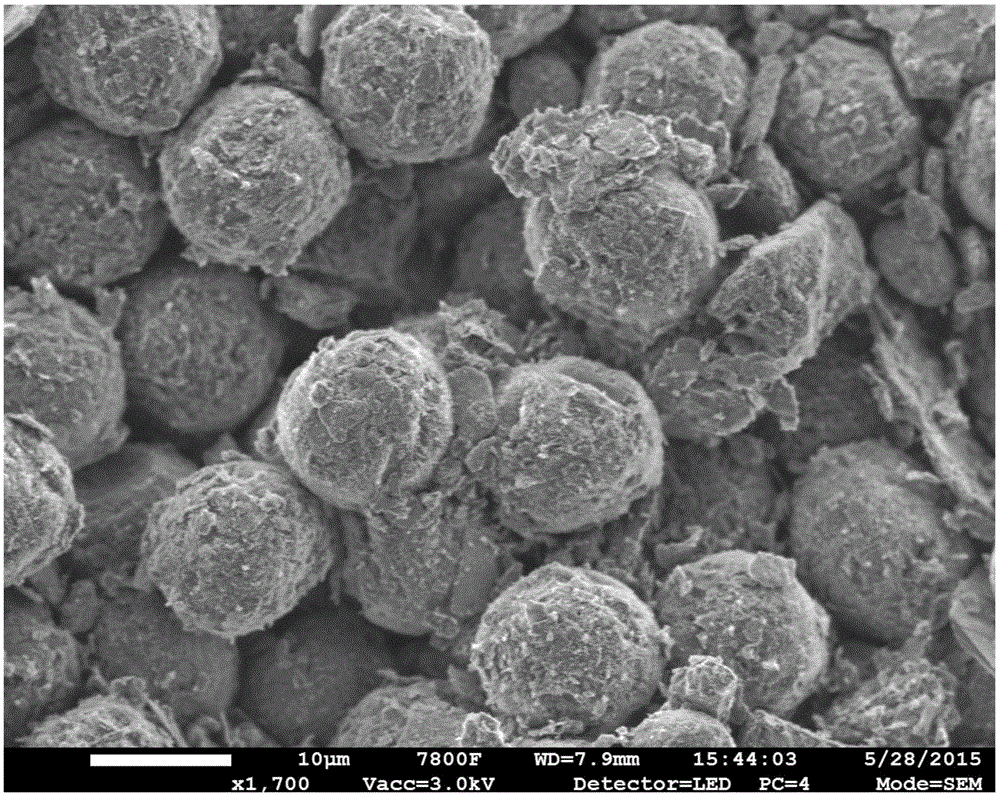

[0039] Example 2: The difference between this embodiment and specific example 1 is: the specific preparation steps of silane reagent-modified magnesium oxide microspheres in step (1) are: a. Using magnesium nitrate and potassium carbonate in the crystals of basic magnesium carbonate The precursor of magnesium oxide is prepared under kind induction, the secondary product is fully washed and vacuum dried, and finally calcined at high temperature, sieved, and settled to obtain magnesium oxide microspheres with a particle size of 8-15 μm; b. The magnesium oxide microspheres are vacuum dried at 50-100°C. In an anhydrous toluene system, add a certain quality of dry magnesium oxide microspheres and surfactants, reflux for 1 to 3 hours, and the volume ratio of the added magnesium oxide microspheres to toluene is 1g: 20-60 mL, and magnesium oxide is added The mass ratio of the microspheres to the surfactant mass is 100:1 to 500:1. Under the condition of magnetic stirring, add a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com