Follow-up pressure-holding flexible stretch forming machine based on vertical loading

A vertical loading and stretch forming technology, applied in the field of plastic processing equipment and passive stretch flexible stretch forming device, can solve the problems of complicated operation, high cost of flexible stretch forming device, difficult to control, etc., to achieve stress and strain. The effect of uniform distribution, reducing defects of formed parts and improving the quality of formed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

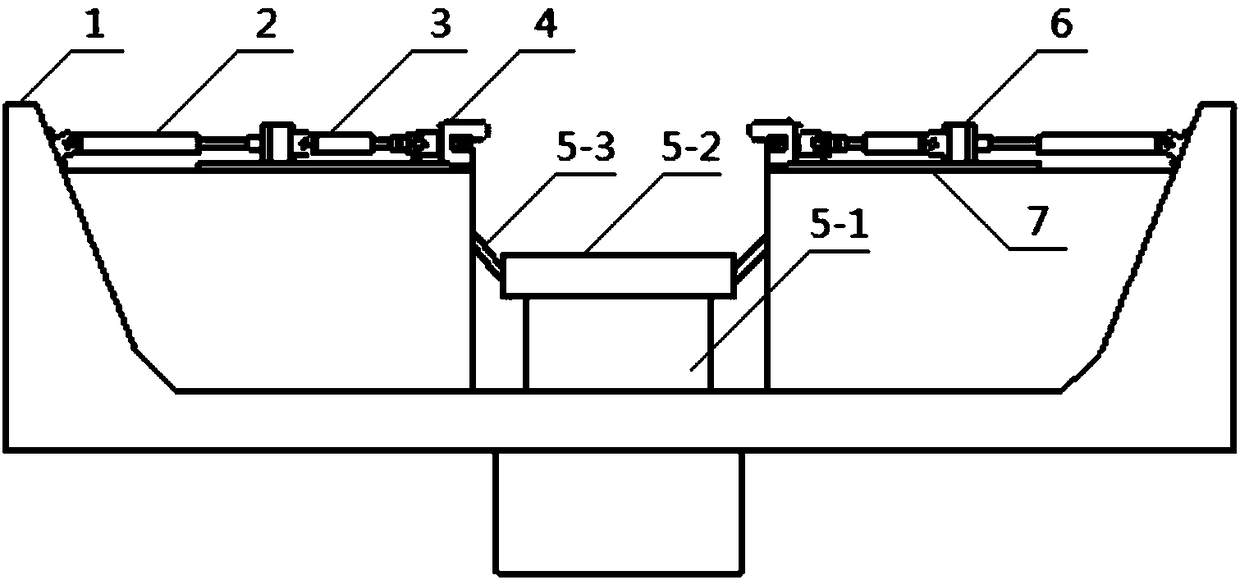

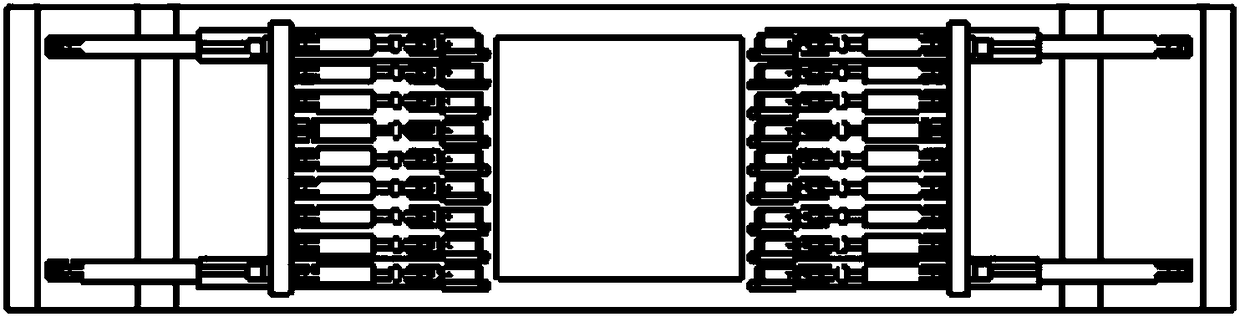

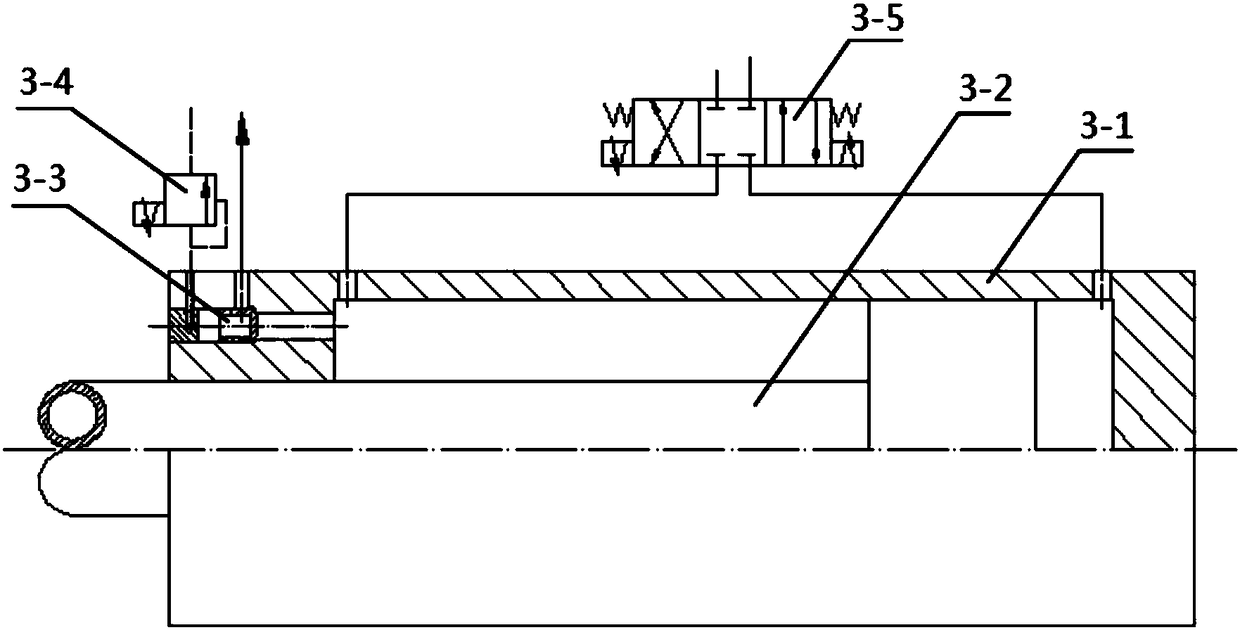

[0023] The flexible passive stretch forming forming device of the present invention mainly consists of a frame 1 and a set of pre-stretching mechanisms 2 at the left and right ends of the frame 1, a row of multiple follow-up pressure maintaining mechanisms 3 and clamping mechanisms 4, and a set of Vertical loading mechanism 5 is formed. The pre-stretching mechanism 2 is hinged with the follow-up pressure maintaining mechanism 3 through the horizontal moving bar 6, and the horizontal moving bar 6 is slidingly matched with the guide rail 7 horizontally fixed on the frame 1. The follow-up pressure maintaining mechanism 3 is connected with the clamping mechanism 4, and flexibly connected with the workbench on the vertical loading mechanism 5 through the damping support mechanism, and the stretch forming m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com