Right-angled rail-type assembly platform for steel structures

A sliding rail type, steel structure technology, applied in the workbench, auxiliary device, auxiliary welding equipment and other directions, can solve the problem of difficulty in ensuring accuracy and product quality, and achieve the purpose of improving the flexibility of use, improving the versatility, and increasing the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

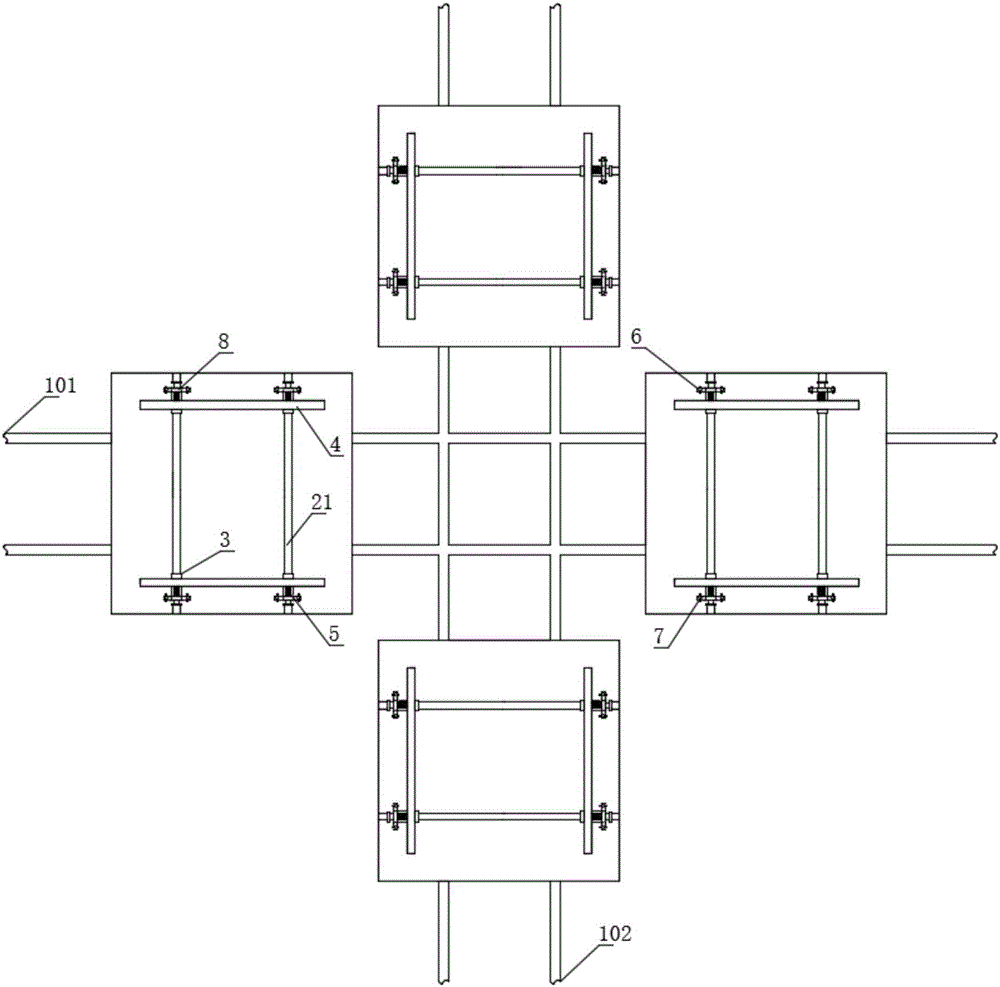

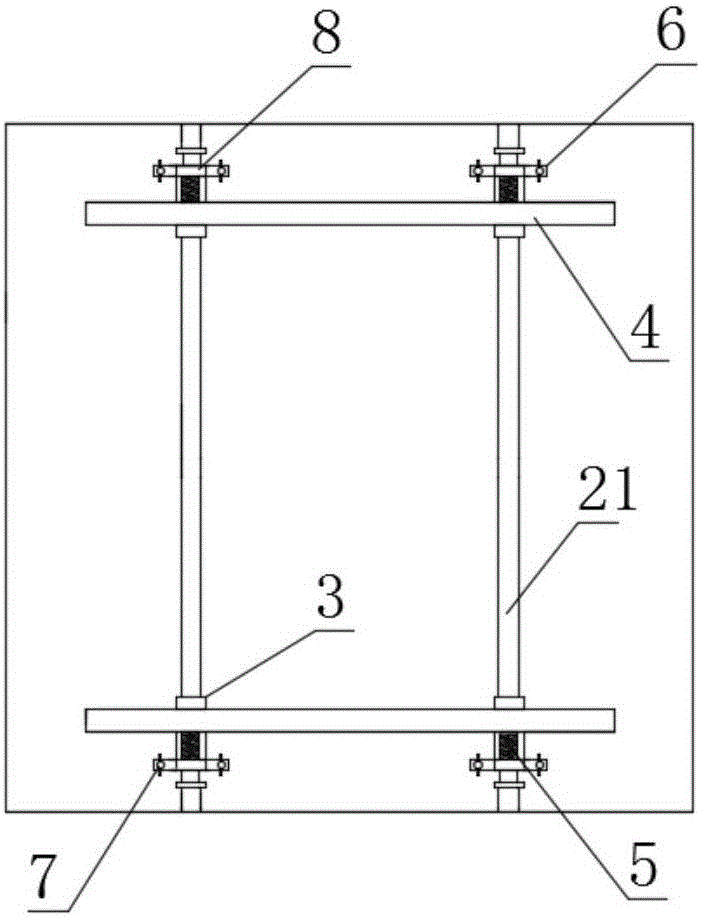

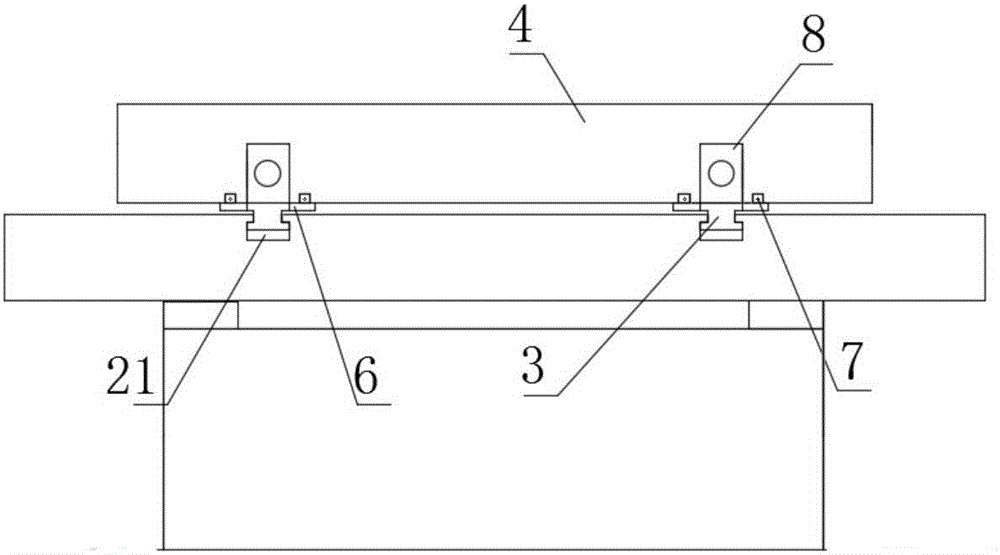

[0016] Such as Figures 1 to 5 As shown, this embodiment provides a right-angle slide rail type steel structure assembly platform, including a slide rail and a clamping platform; 102; two clamping platforms are movably installed on the horizontal slide rail 101 and the longitudinal slide rail 102; the clamping platform includes a base 1, a table top 2 and two clamping mechanisms; the bottom of the base 1 is provided with a slide Slot 11; it is installed on the slide rail through the chute 11; the table top 2 is movably arranged on the top of the base 1 through the turntable 12, and the upper surface of the table top 2 is provided with two slideways 21 arranged in parallel, and the slideways 21 The cross-section is a convex structure; two clamping mechanisms are arranged oppositely, and the clamping mechanism includes two sliders 3, strip splints 4 and positioning bolts 7; the two sliders 3 are respectively slidably installed on the two In a slideway 21, the cross section of t...

Embodiment 2

[0018] Such as Figures 1 to 5 As shown, this embodiment provides a right-angle slide rail type steel structure assembly platform, different from Embodiment 1, preferably, the movable end of the sliding shaft 51 is provided with an anti-off block 53; the upper surface of the table 2 is provided with There are multiple strip-shaped holes; a collecting hopper is arranged in the base 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com