Glaze spraying device for domestic ceramic

A technology for spraying glaze and ceramics, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of low quality of spraying glaze and low efficiency of spraying equipment, and achieve the effect of improving labor efficiency, saving resources and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

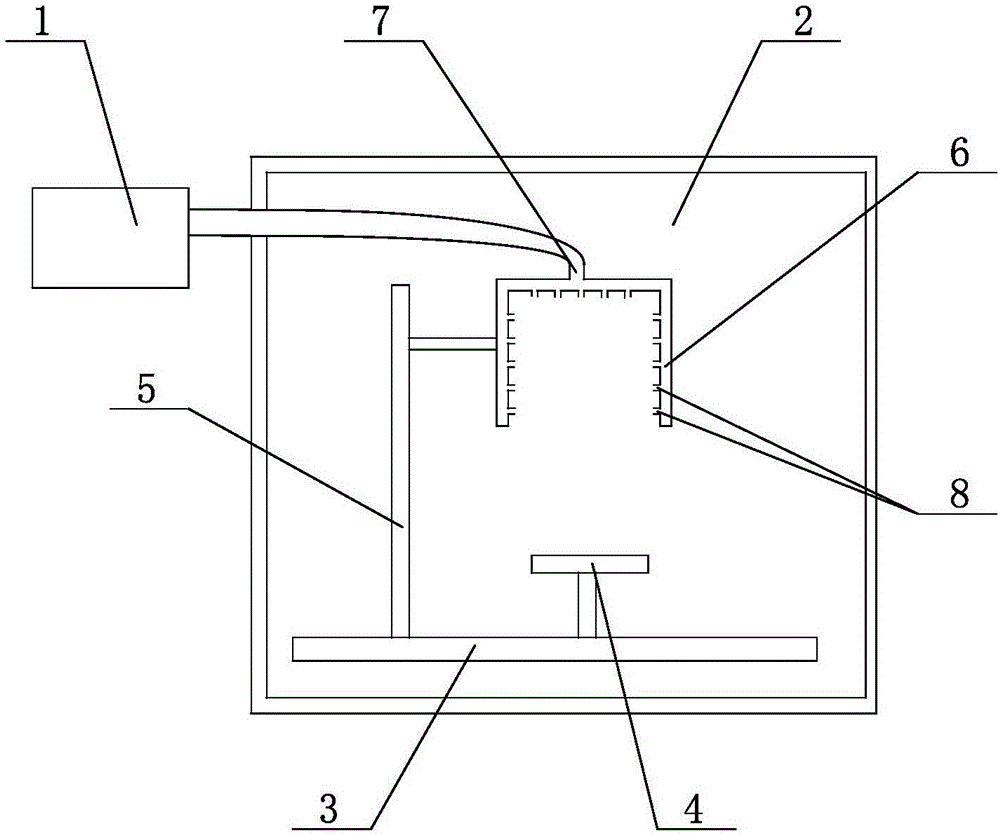

[0022] Such as figure 1 As shown, the present invention is a kind of glaze spraying device for daily-use ceramics, comprising a glaze spraying chamber 1, a glaze supply device 2, and the glaze spraying chamber includes a workbench 3, and the workbench is provided with a storage board 4 and a support 5, The bracket is provided with a vertical slide rail, and the glaze spray chamber is also provided with a glaze spray cover 6, and the lower end of the spray glaze cover is provided with an opening, and the spray glaze cover is connected with the support through a slider, and the glaze spray cover is located at the bottom of the storage board. Directly above; the wall of the glaze spray cover is hollow, and the top outer wall of the glaze spray cover is provided with a glaze inlet 7, which is connected with the glaze supply device; the inner wall of the glaze spray cover is evenly provided with a plurality of glaze spray ports 8.

[0023] The glaze spraying device of the present i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap