Railway nonstandard container transportation flatcar

A non-standard container and container lock technology, which is applied in the direction of railway transportation, railway transportation, passenger car transportation, etc., can solve the problems of insufficient container flat car inventory, rapid growth of container transportation volume, standardization level of vacancy of large containers, insufficient carrying capacity, etc. , to improve reliability and safety, prolong service life and reduce self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the drawings.

[0036] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

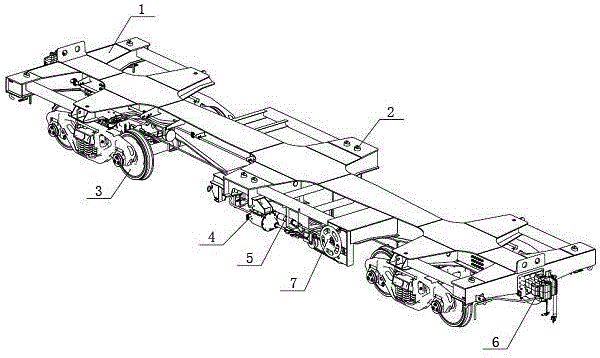

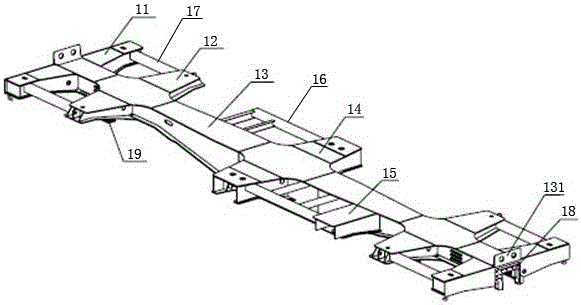

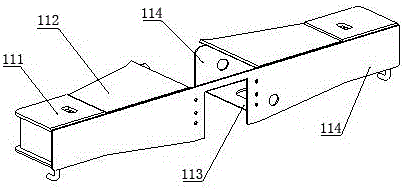

[0037] Such as figure 1 As shown, a railway non-standard container transport flat car includes an underframe 1, a container locking device 2, a bogie 3, an air brake device 4, an underframe attachment 5, a coupler buffer device 6 and a hand brake device 7 The underframe 1 includes an end beam 11, a corbel 12, a middle beam 13, and a large cross beam 14. The underframe 1 is an overall fishbone-shaped load-bearing structure that is obliquely symmetrical with respect to the middle beam 13, and is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com