Unidirectionally-sliding anti-winding track drive wheel

A track-driven, one-way sliding technology, used in tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as loss, damage to track structure, and impact on work tasks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

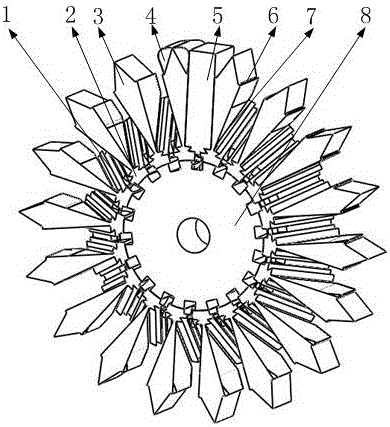

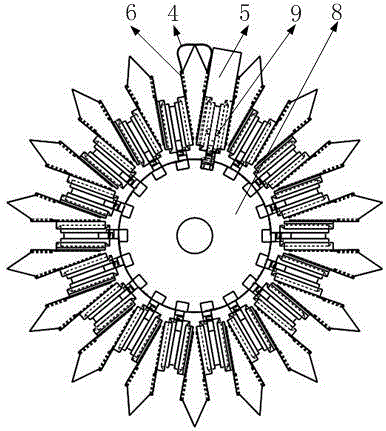

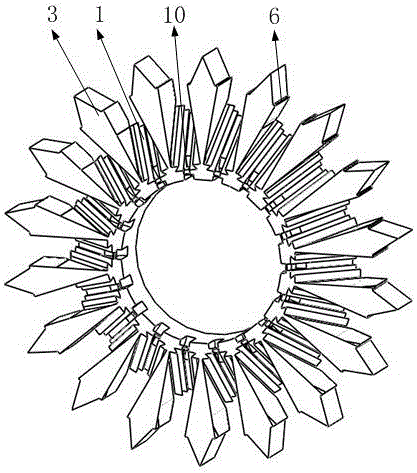

[0021] Such as figure 1 , 2 As shown, it includes chute 1, driving wheel ring 2, driving horn 3, retaining spring 4, block 5, retaining spring groove 6, guide groove 7, center wheel 8, card hole 9, transmission chamber 10, wheel groove 11. The first gear 13, the second gear 15, the block cavity, the female block 17, the sub block 18, the second gear shaft 19, the block tooth groove 20, the guide block 21, the inclined rail 22, the block rack 23, The first gear shaft 24, wherein as Figure 4 As shown, there are 18 wheel grooves 11 on the outer edge surface of the center wheel 8, and the center wheel 8 is connected with the drive shaft of the vehicle; as image 3 As shown, 18 driving corners 3 are evenly installed on the outer edge of the driving wheel ring 2 in the circumferential direction, and there is a chute 1 between two adjacent driving corners 3, and the chute 1 faces the side of the driving wheel ring 2 Inclined at 45 degrees; on the chute 1, there is a transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com