Stacker crane with function of automatically adjusting cargo placing position

A technology of placement and automatic adjustment, applied in the field of palletizers, can solve problems such as barcodes not facing the scanner, and achieve the effect of high feasibility and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

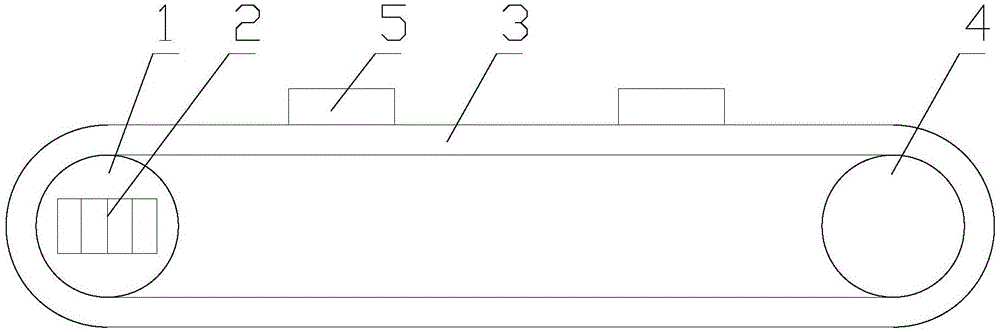

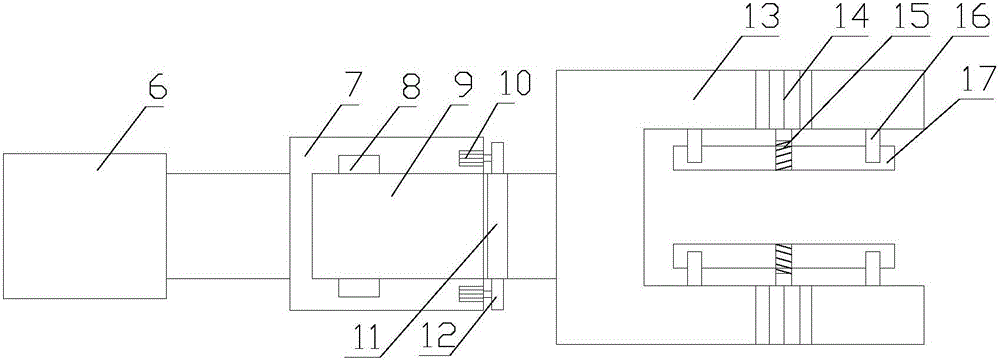

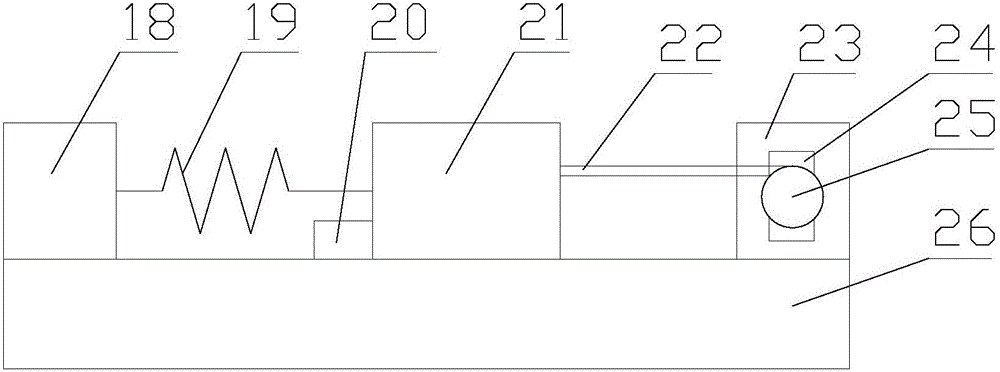

[0026] Such as Figure 1-4 As shown, a palletizer with the function of automatically adjusting the position of goods. The middle and low position palletizers are mainly composed of flattening conveyors, slow stop conveyors, indexing conveyors, pallet bins, pallet conveyors, marshalling machines, It is composed of a bag pushing device, a palletizing device, and a pallet conveyor, and the pallet conveyor also includes a driving mechanism, a PLC, a detection mechanism 5 and an adjustment mechanism;

[0027] The drive mechanism includes a first motor 2, a drive wheel 1, a driven wheel 4, and a transmission belt 3. The first motor 2 drives the drive wheel 1 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com