A kind of preparation method of 4n high-purity lithium carbonate

A high-purity lithium carbonate, pure water technology, applied in lithium carbonate;/acid carbonate and other directions, can solve the problems of high price, high cost and increased process of battery-grade lithium hydroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

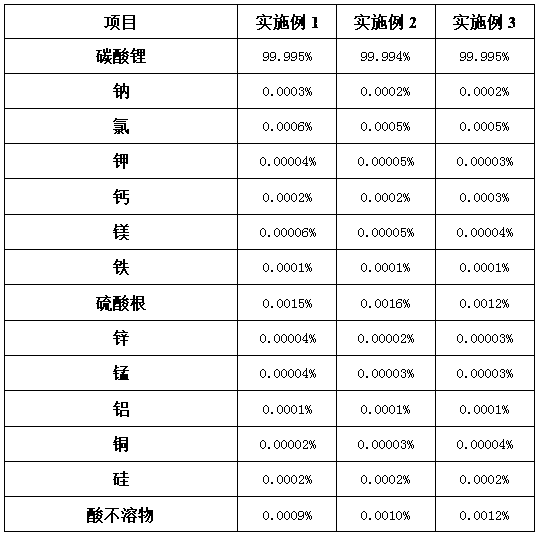

Examples

Embodiment 1

[0013] Step 1: Add 3000L of pure water into a 5000L dissolution tank, start stirring, add industrial grade lithium hydroxide to fully dissolve and prepare a lithium hydroxide solution with a lithium content of 35g / L, and then use a membrane to precisely conduct lithium hydroxide solution Filter to obtain the fine filtrate of lithium hydroxide, and add 5 kilograms of EDTA in the fine filtrate of lithium hydroxide to stir and fully dissolve EDTA to obtain a refined solution of lithium hydroxide;

[0014] Step 2: First add 500L of pure water to the 1000L lithium carbonization kettle with an overflow as the bottom liquid, and raise the temperature of the bottom liquid to 80°C while stirring, and then keep it at 80°C while stirring. Continuously add the refined lithium hydroxide solution obtained in step 1 to the liquid and continuously pass carbon dioxide gas into the bottom liquid to carry out the carbonization lithium precipitation reaction, control the adding speed of the refine...

Embodiment 2

[0016] Step 1: Add the carbonized mother liquor that step 2 obtains in 3000L embodiment 1 in the dissolving tank of 5000L, add technical grade lithium hydroxide after starting to stir and fully dissolve and be prepared to contain lithium and be the lithium hydroxide solution of 45g / L, then use Finely filter the lithium hydroxide solution with the membrane to obtain a lithium hydroxide fine filtrate, and add 0.1 kg of EDTA to the lithium hydroxide fine filtrate to stir to fully dissolve the EDTA to obtain a lithium hydroxide refined solution;

[0017] Step 2: First add 500 L of the carbonized mother liquor obtained in Step 2 of Example 1 into a 1000 L carbonization lithium precipitation kettle with an overflow port as the bottom liquid, and raise the temperature of the bottom liquid to 98 °C under stirring, and then keep it at 98 °C Synchronously add the refined lithium hydroxide solution obtained in step 1 to the bottom liquid under stirring, and continuously pass carbon dioxid...

Embodiment 3

[0019] Step 1: Add 2000L of pure water and 1000L of the carbonized mother liquor obtained in step 2 of Example 1 into a 5000L dissolution tank, start stirring and mixing, then add industrial-grade lithium hydroxide to fully dissolve and prepare hydrogen containing 40g / L of lithium Lithium oxide solution, and then the lithium hydroxide solution is finely filtered with a membrane to obtain a lithium hydroxide fine filtrate, and 2 kg of EDTA is added to the lithium hydroxide fine filtrate to stir and the EDTA is fully dissolved to obtain a lithium hydroxide refined solution;

[0020] Step 2: First add 200L of pure water and 300L of the carbonized mother liquor obtained in step 2 of Example 1 into a 1000L carbonization lithium precipitation kettle with an overflow port as the bottom liquid, and heat the bottom liquid to 90°C while stirring, Then keep 90°C under agitation and simultaneously add the refined lithium hydroxide solution obtained in step 1 to the bottom liquid continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com