Reaction kettle for preparing nano calcium carbonate

A nano-calcium carbonate, reaction kettle technology, applied in the direction of calcium carbonate/strontium/barium, nanotechnology, etc., can solve the problem of waste of cooling medium, and achieve the effect of avoiding a lot of waste and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

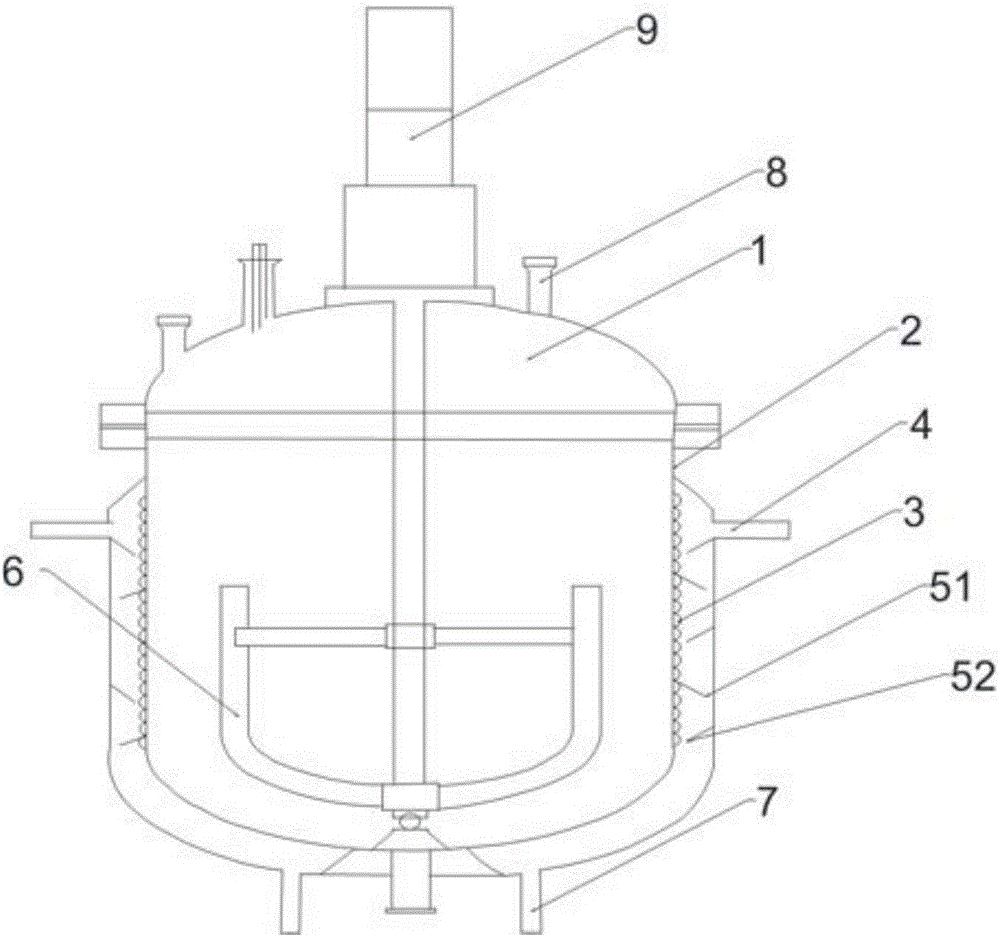

[0022] Such as figure 1 As shown, the reaction kettle for preparing nano-calcium carbonate includes a cylinder body 2, a cylinder cover 1, and the cylinder cover 1 is covered on the cylinder body 2. The cylinder cover 1 is provided with a carbon dioxide gas inlet 8 and a motor 9, and the cylinder body 2 is provided outside There is a hollow jacket, the jacket covers the outer wall surface except the bottom of the cylinder 2, the cooling medium inlet pipe is arranged above the jacket, the cooling medium outlet pipe 7 is arranged below the jacket, and the first The baffle 51 and the second baffle 52, the first baffle 51 and the second baffle 52 are respectively arranged on the two inner walls in the jacket, and the first baffle 51 and the second baffle 52 For relative misalignment, both the first baffle 51 and the second baffle 52 have holes with the inner wall of the jacket.

[0023] The idea of the present invention is that the inventors have found that the existing problem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com