A kind of synthetic method of selinexor crude drug

A synthetic method and raw material drug technology, which is applied in the field of synthesis of Selinexor raw material drug, can solve problems such as affecting the yield and difficult to remove, and achieve the effect of reducing synthesis steps and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

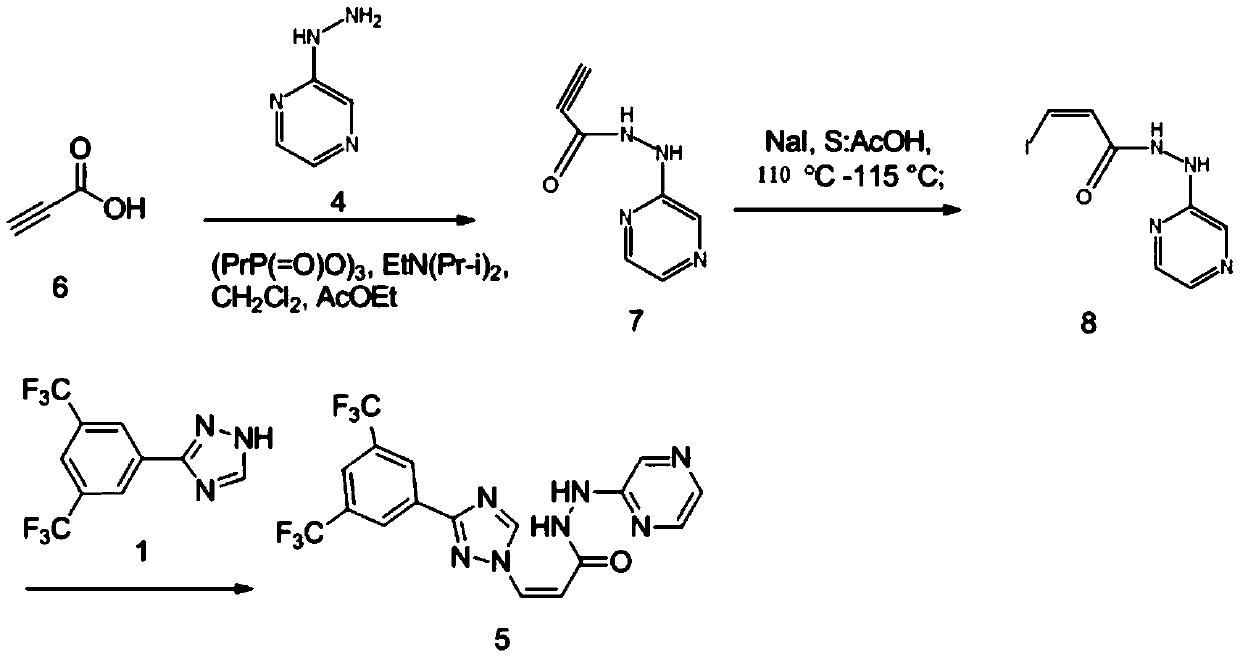

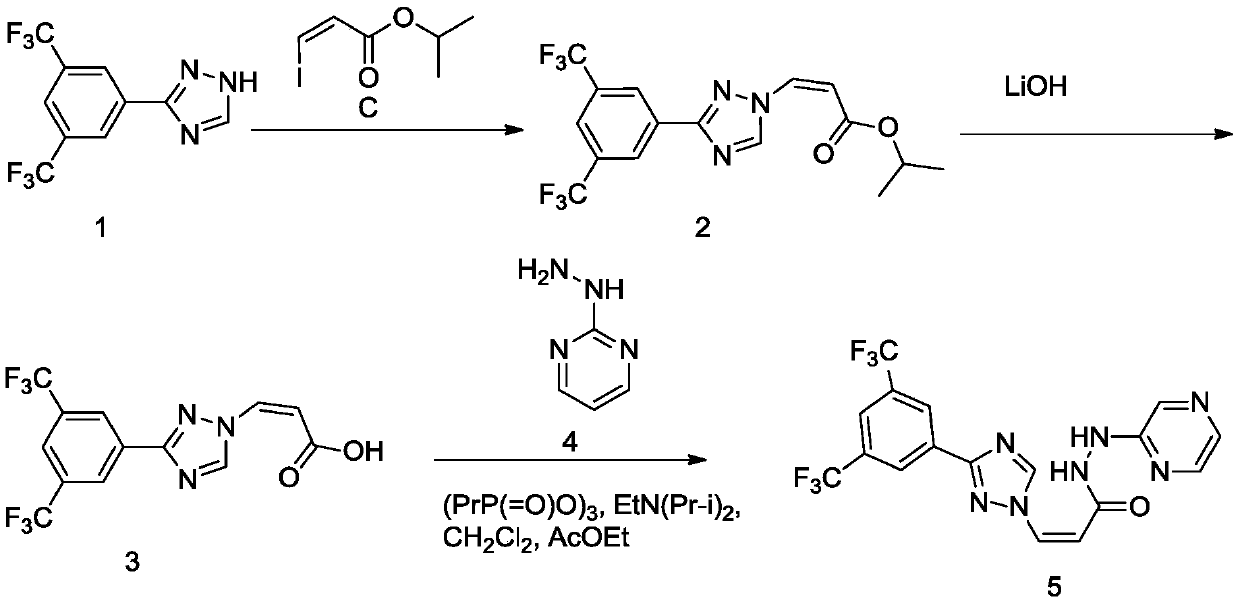

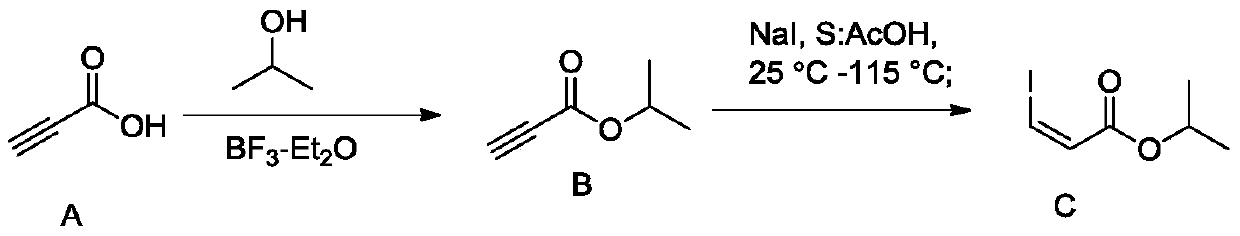

[0024] A synthetic method of Selinexor bulk drug, comprising the following steps:

[0025] A. Synthesis of compound 7

[0026] In a 50ml three-necked flask, add 0.2g of compound 6, 15ml of dichloromethane and 15ml of ethyl acetate, stir to dissolve, add 0.3g of compound 4 and 3g of T at 0°C 3 P, 0.75g DIPEA; the system was stirred at 0°C for 30min to react, after the reaction was completed, 50ml of dichloromethane and 30ml of water were added, the layers were separated, the organic phase was evaporated to dryness to obtain a crude product of compound 7, and the crude product was directly dropped without purification;

[0027] B. Synthesis of Compound 8

[0028] In a 50ml three-necked flask, add compound 7 obtained in the previous step, 40ml of glacial acetic acid and 1.38g of sodium iodide, heat up to 115°C, and react for 3h; after the reaction, the system is lowered to room temperature, the system is transferred to a 500ml bottle, and 50ml of Water and 100 ml of dichloromet...

Embodiment 2

[0032] A synthetic method of Selinexor bulk drug, comprising the following steps:

[0033] A. Synthesis of compound 7

[0034] In a 50ml three-necked flask, add 0.2g of compound 6, 15ml of dichloromethane and 15ml of ethyl acetate, and after stirring to dissolve, add 0.3g of compound 4 and 3g of T at 1°C 3 P, 0.75g DIPEA; the system was stirred at 1°C for 35min to react, after the reaction was completed, 50ml of dichloromethane and 30ml of water were added, the layers were separated, the organic phase was evaporated to dryness to obtain a crude product of compound 7, and the crude product was directly dropped without purification;

[0035] B. Synthesis of Compound 8

[0036] In a 50ml three-necked flask, add compound 7 obtained in the previous step, 40ml of glacial acetic acid and 1.38g of sodium iodide, heat up to 120 ° C, and react for 2.5h; 60ml of water and 120ml of dichloromethane, stirred for 15min, left to separate layers, the organic phase was washed with saturated s...

Embodiment 3

[0040] A synthetic method of Selinexor bulk drug, comprising the following steps:

[0041] A. Synthesis of compound 7

[0042] In a 50ml three-necked flask, add 0.2g of compound 6, 15ml of dichloromethane and 15ml of ethyl acetate, and after stirring to dissolve, add 0.3g of compound 4 and 3g of T at 2°C 3 P, 0.75g DIPEA; the system was stirred at 0°C for 25min to react, after the reaction was completed, 40ml of dichloromethane and 35ml of water were added, the layers were separated, the organic phase was evaporated to dryness to obtain a crude product of compound 7, and the crude product was directly dropped without purification;

[0043] B. Synthesis of Compound 8

[0044] In a 50ml three-necked flask, add compound 7 obtained in the previous step, 35ml of glacial acetic acid and 1.38g of sodium iodide, heat up to 110 ° C, and react for 3.5h; 50 ml of water and 100 ml of dichloromethane were stirred for 8 min, and then left to separate layers. The organic phase was washed w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap