A kind of building waterproof asphalt caulking ointment and preparation method thereof

A building waterproof and asphalt technology, which is applied to buildings, building components, building structures, etc., can solve problems such as adverse effects on overall product performance, unstable product performance, and poor resource utilization, and achieve great resource advantages and environmental protection. Heat resistance for maximum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the building waterproof asphalt caulking ointment described in the above technical solution, comprising the following steps:

[0043] a) subjecting the rubber powder to microwave activation treatment to obtain activated rubber powder;

[0044] b) Mix asphalt, oil slurry, activated rubber powder, diluent and filler, and react to obtain building waterproof asphalt caulking ointment.

[0045] In the invention, firstly, the rubber powder is subjected to microwave activation treatment to obtain activated rubber powder. In the present invention, the rubber powder is the same as that described in the above technical solution, and will not be repeated here. In the present invention, the purpose of the microwave activation treatment is to increase the active sites of the rubber powder, so that the subsequent reaction can proceed smoothly, thereby obtaining a product with better performance. In the present invention, t...

Embodiment 1

[0062] (1) Activate the rubber powder in a JK-MCR-201 microwave chemical reactor at 200 mA for 4 minutes to obtain activated rubber powder;

[0063] (2) Add 100g of asphalt and 50g of oil slurry into a 1L reaction kettle, heat and melt to obtain the base material; then add 70g of waste engine oil, 40g of activated rubber powder and 30g of wood powder, heat up to 170°C and react for 110min to obtain viscous Reaction mixture; then lower the temperature to 150°C, add 50g cyanamide slag, 50g desulfurized gypsum and 50g thiourea slag, and add 10g turpentine, and stir until uniform to obtain building waterproof asphalt caulking ointment.

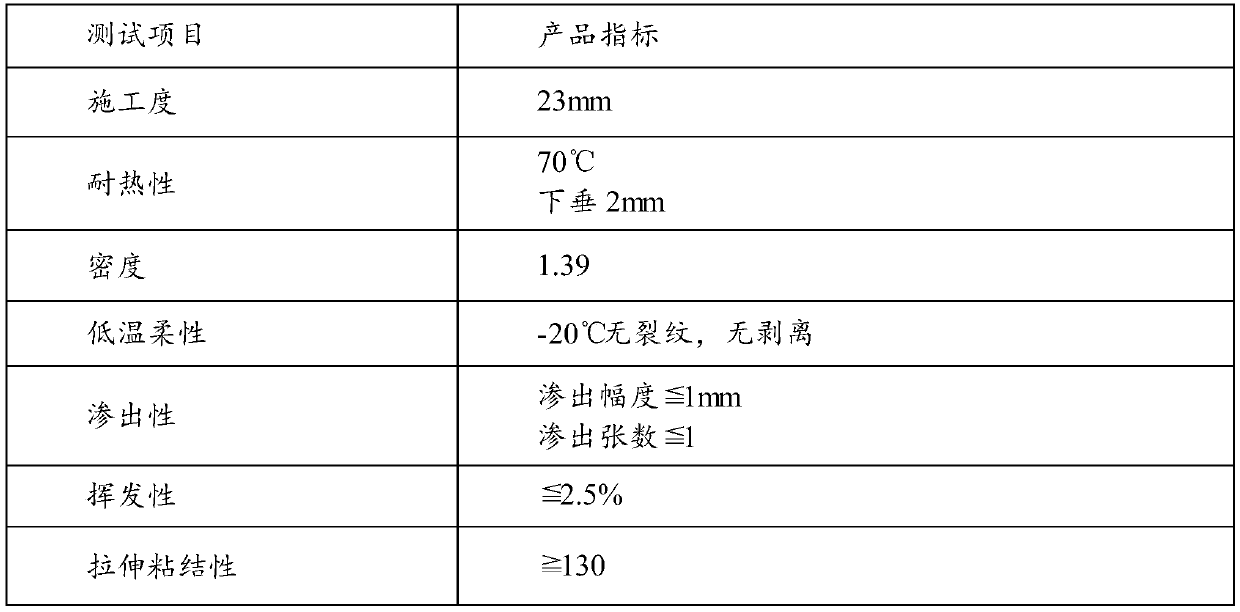

[0064] JC / T 207-2011 was used to test various properties of the building waterproof asphalt caulking ointment obtained in Example 1, and the results are shown in Table 1.

[0065] The various performance data of the building waterproof asphalt caulking ointment that table 1 embodiment 1 obtains

[0066]

Embodiment 2

[0068] (1) Activate the rubber powder in a JK-MCR-201 microwave chemical reactor at 200 mA for 4 minutes to obtain activated rubber powder;

[0069] (2) Add 100g of asphalt and 50g of oil slurry into a 1L reactor, heat and melt to obtain the base material; then add 70g of waste engine oil, 40g of activated rubber powder and 30g of wood powder, and heat up to 200°C for 45 minutes to obtain a viscous Reaction mixture; then lower the temperature to 150°C, add 100g of desulfurized gypsum and 50g of thiourea slag, and add 10g of turpentine, stir until uniform, and obtain building waterproof asphalt caulking ointment.

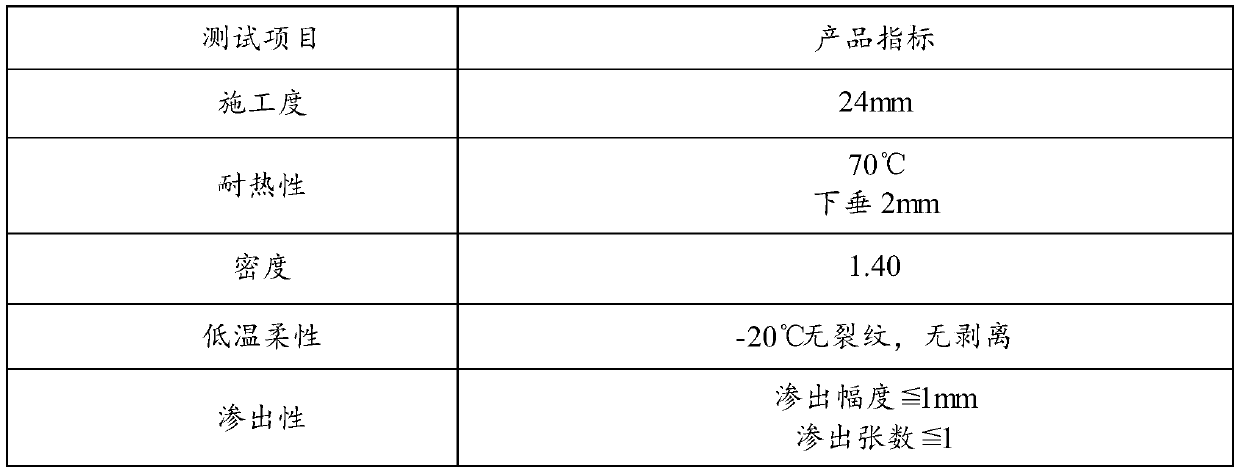

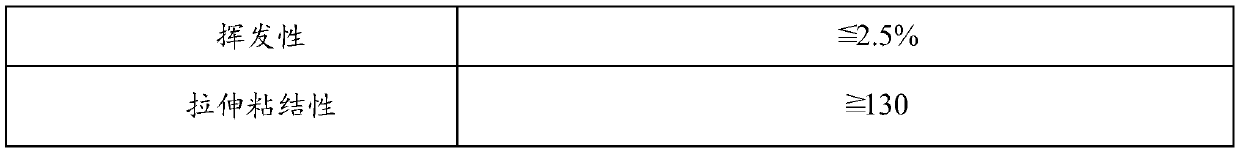

[0070] The method provided in Example 1 was used to test various properties of the building waterproof asphalt caulking ointment obtained in Example 2, and the results are shown in Table 2.

[0071] The performance data of the building waterproof asphalt caulking ointment that table 2 embodiment 2 obtains

[0072]

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com