A kind of method that takes sherwood oil and methanol as raw material to prepare gasoline

A technology of petroleum ether and methanol, applied in the field of oil processing, to achieve the effects of reducing gas products, simple reaction equipment, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

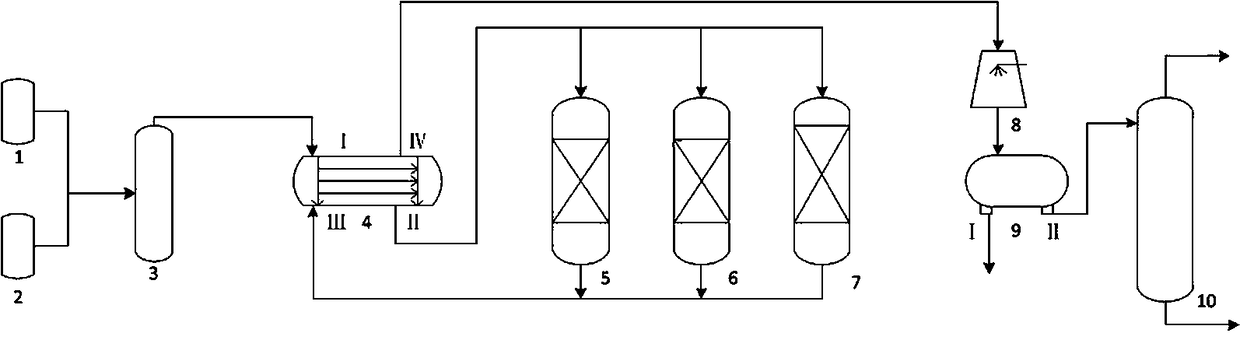

[0025] The molecular sieve catalyst is prepared by spray drying method, the silicon-aluminum ratio of ZSM-5 molecular sieve is 100, and the weight ratio of ZSM-5 molecular sieve: kaolin: silica sol is 3:3:1. Petroleum ether and methanol with a weight ratio of 4:1 are used as raw materials. The raw materials enter the vaporizer 3, the temperature of the vaporizer is 270°C, and enter the reactors 5, 6, and 7 through the heat exchanger 4, and react in the catalyst bed, and the reaction temperature is 350°C. , the reaction pressure is 1.5MPa, and the weight space velocity of the raw material is 8h -1 . The reaction product enters the cooler 8 through the heat exchanger 4, and enters the oil-water separator 9 after cooling to separate the water, and the oil product enters the distillation tower 10 for separation to obtain gasoline, liquefied gas and dry gas. The reaction results are shown in Table 1.

Embodiment 2

[0027] The molecular sieve catalyst is prepared by spray drying method, the silicon-aluminum ratio of ZSM-5 molecular sieve is 100, and the weight ratio of ZSM-5 molecular sieve: kaolin: silica sol is 3:3:1. Using petroleum ether and methanol with a weight ratio of 5:1 as raw materials, the raw materials enter the vaporizer 3, the temperature of the vaporizer is 270°C, and enter the reactors 5, 6, and 7 through the heat exchanger 4, and react in the catalyst bed, the reaction temperature is 350°C , the reaction pressure is 1.5MPa, and the weight space velocity of the raw material is 8h -1 . The reaction product enters the cooler 8 through the heat exchanger 4, and enters the oil-water separator 9 after cooling to separate the water, and the oil product enters the distillation tower 10 for separation to obtain gasoline, liquefied gas and dry gas. The reaction results are shown in Table 1.

Embodiment 3

[0029] The molecular sieve catalyst is prepared by spray drying method, the silicon-aluminum ratio of ZSM-5 molecular sieve is 20, and the weight ratio of ZSM-5 molecular sieve: kaolin: silica sol is 2:4:1. Using petroleum ether and methanol with a weight ratio of 5:1 as raw materials, the raw materials enter the vaporizer 3, the temperature of the vaporizer is 180°C, and enter the reactors 5, 6, and 7 through the heat exchanger 4, and react in the catalyst bed layer, and the reaction temperature is 200°C , the reaction pressure is 5.0MPa, and the weight space velocity of the raw material is 0.1h -1 . The reaction product enters the cooler 8 through the heat exchanger 4, and enters the oil-water separator 9 after cooling to separate the water, and the oil product enters the distillation tower 10 for separation to obtain gasoline, liquefied gas and dry gas. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com