Long-span highway anti-dazzle separating mesh

A technology of isolation nets and spans, which is applied in the direction of protective equipment and buildings, can solve problems such as lengthening of separation distances, drooping of anti-glare isolation nets, etc., and achieve the effect of increasing structural strength, convenient installation and maintenance and replacement, and good dynamic vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

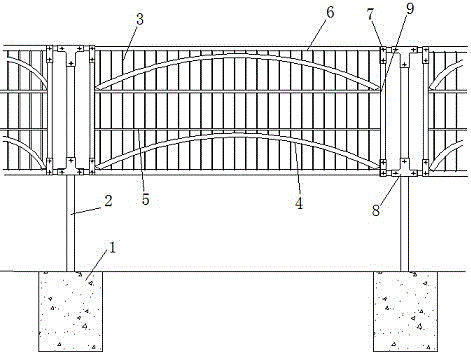

[0049] Such as figure 1 As shown, the present embodiment provides a long-span highway anti-glare isolation net, including an isolation grid arranged between two adjacent columns 2, the isolation grid mainly consists of a frame and several vertical bars arranged in the frame. The isolation rod 3 constitutes. The frame includes an upper cross bar 6, a lower cross bar and two left and right vertical bars 9. At least one of the upper cross bar 6 or the lower cross bar of the isolation grid is arched, or when the upper cross bar 6 and the lower cross bar are straight, at least one is arranged between the upper cross bar 6 and the lower cross bar An arched tendon 4. Arched tendons are straight in the free state, or have a lesser curvature than when spacer rods are worn. Spacer rod 3 and rib, upper cross bar 6, and lower cross bar are interspersed structures, and ribs, upper cross bar 6 and lower cross bar are provided with holes, and spacer bar 3 passes through upper cross bar 6,...

Embodiment 2

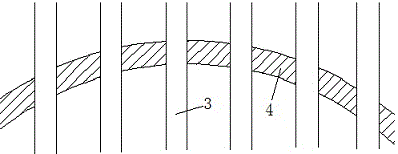

[0054] Such as Figure 4 As shown, a long-span highway anti-glare isolation net provided by this embodiment is exactly the same as that of Embodiment 1 in terms of the structure of the column, the frame and the isolation rod, and the connection mode between the components, except that :

[0055] This embodiment includes a straight rib 5 and two arched ribs 4 , and the two arched ribs 4 are respectively located above and below the straight rib 5 . The curved shape of the upper arched tendon 4 is downward bending, and the curved shape of the lower arched rib 4 is upward arch.

Embodiment 3

[0057] Such as Figure 5 As shown, a long-span highway anti-glare isolation net provided by this embodiment is exactly the same as that of Embodiment 1 in terms of the structure of the column, the frame and the isolation rod, and the connection mode between the components, except that :

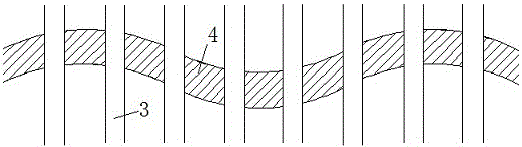

[0058] This embodiment includes a straight rib 5 and an arched rib 4 , and the arched rib is located above the straight rib 5 . The curved shape of the arched ribs 4 is wavy. Such as figure 2 Shown is a cross-sectional view of the spacer rod 3 passing through the hole of the corrugated rib 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com