Tool-combined-type irregular-angle building formwork

A building template and combined technology, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve the problems of inability to guarantee the quality of poured walls, low reuse rate, low work efficiency, etc., and achieve assembly It is easy to disassemble and operate, increase the service life and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

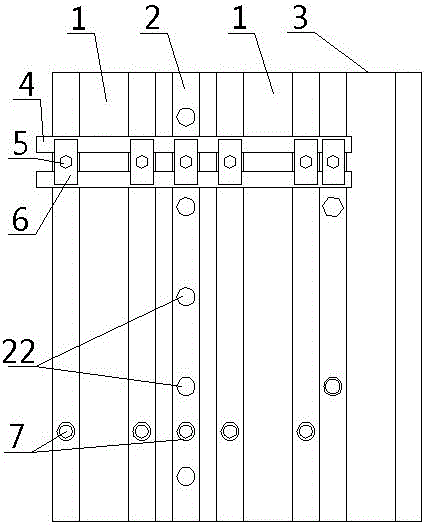

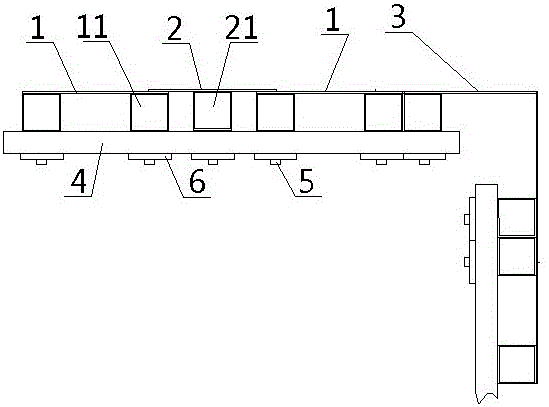

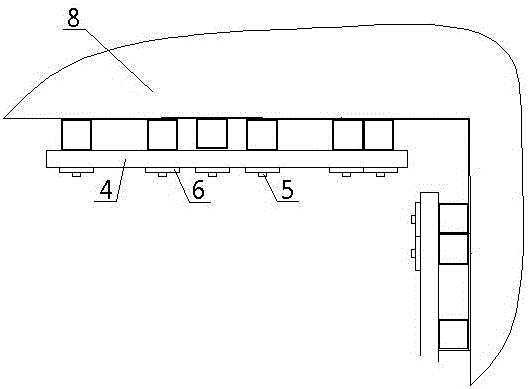

[0038] Accompanying drawing is a kind of specific embodiment of the present invention.

[0039] The tool-combined special-shaped corner building formwork of the present invention is characterized in that it includes a flat formwork 1, an overlapping formwork 2, a special-shaped corner formwork 3 and a reinforcing pipe 4; the front of the flat formwork 1 is a rectangular planar plate structure in contact with the pouring , the back side is fixed with a combination tube with a rectangular support effect, and the flat formwork combination tube 11 is arranged with blind holes 7 perpendicular to the flat formwork and connection through holes parallel to the flat formwork, and the blind holes 7 of the flat formwork combination tube 11 are fixed with threads Collar; the front side of the lap template 2 is a rectangular planar plate structure, and the back side is fixed with a rectangular supporting composite tube, and the lap template composite tube 21 is arranged with vertical and pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com