A Hall thruster with lightweight integrated anode

A Hall thruster, lightweight technology, used in thrust reversers, using plasma, machines/engines, etc., can solve the problem of lack of gas uniformity and buffering characteristics, insignificant advantages in specific impulse performance, and affecting installation and positioning. Accuracy and other issues, to achieve the effect of weight reduction, enhanced ability to withstand harsh mechanical environments, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

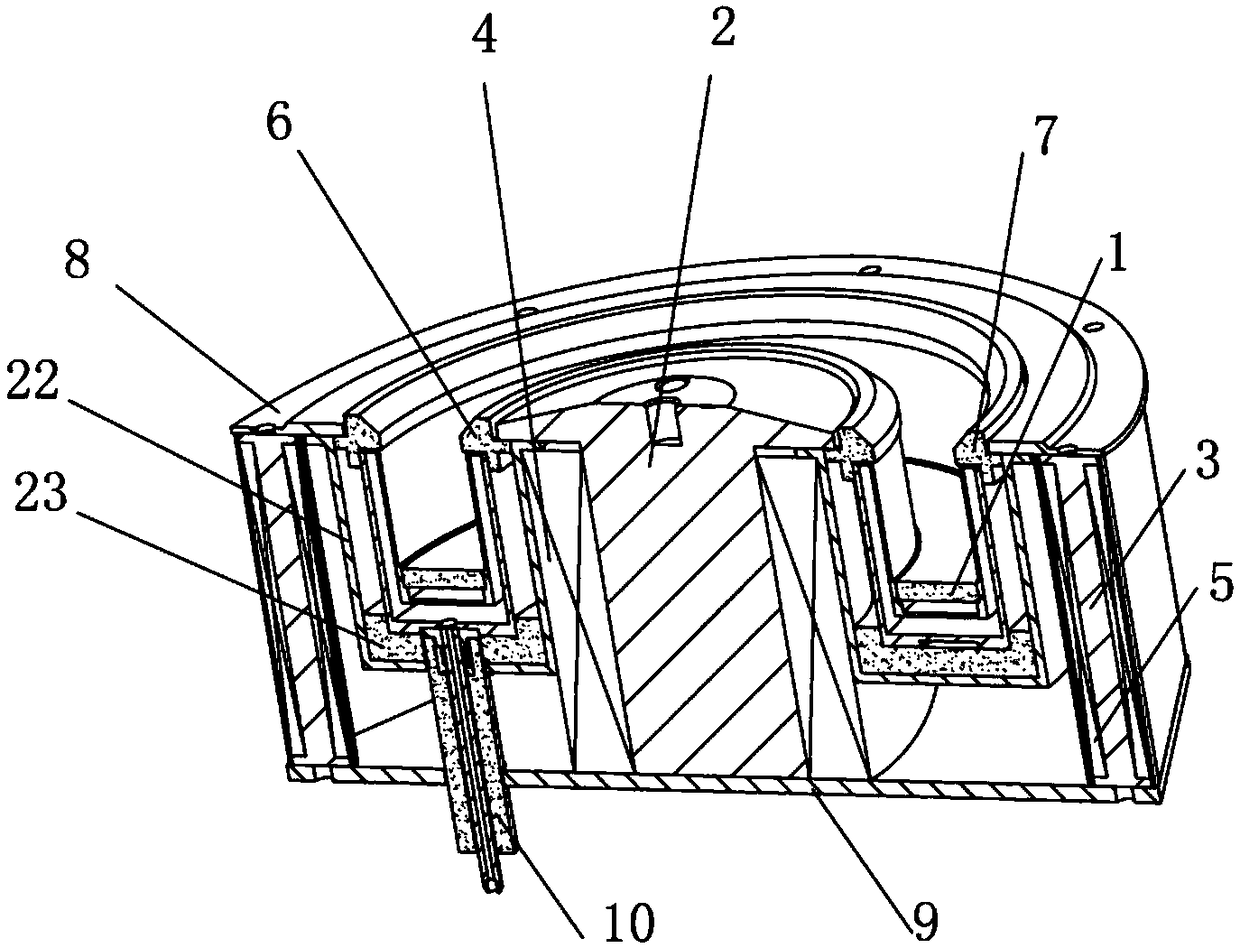

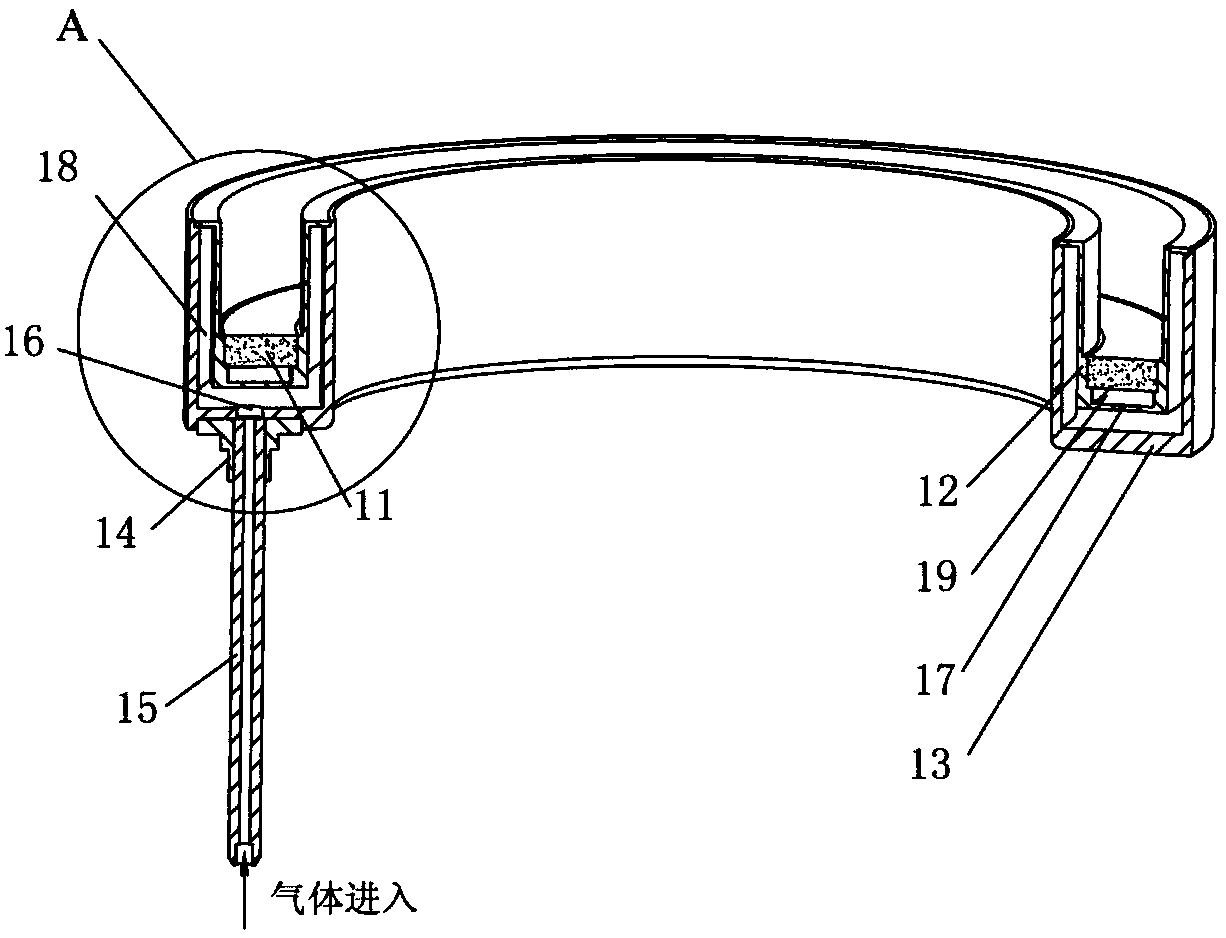

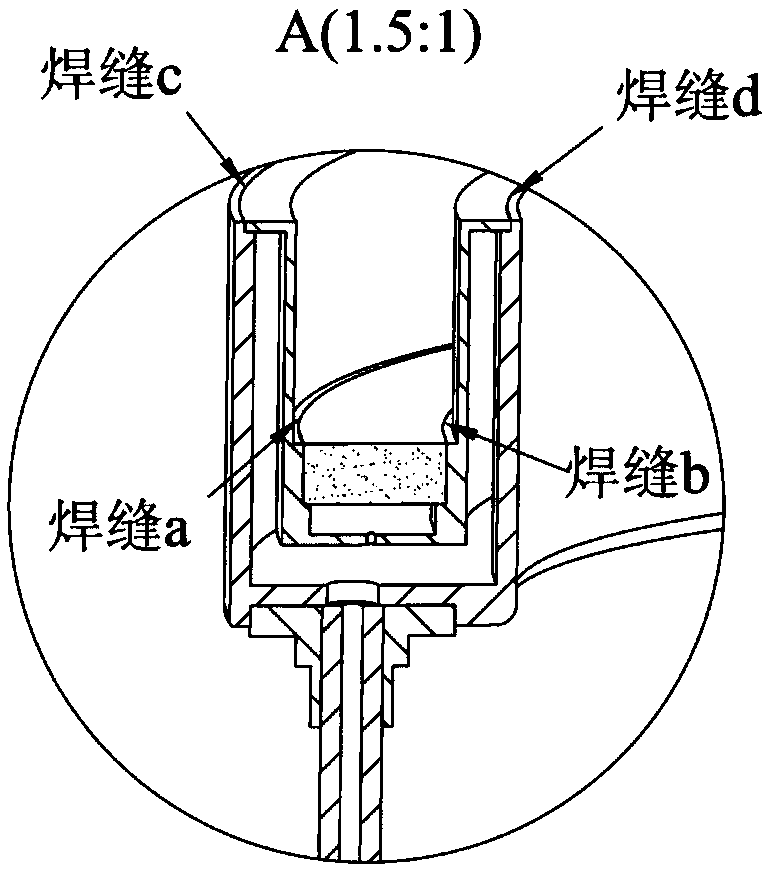

[0039] Such as Figure 2-Figure 4 As shown, the lightweight integrated anode 1 includes an annular porous material plate 11 , an annular side wall 12 , an annular base 13 , an air pipe support 14 , an air pipe 15 , a primary air inlet 16 , and a secondary air inlet 17 . The annular porous material plate 11 is nested in the annular side wall 12, and the outer and inner welds (weld a, b) are welded by electron beam welding to form a secondary distribution cavity 19, which is welded by electron beam A first-level distribution cavity 18 is formed on the ring-shaped base 13 made of stainless steel. The first-level distribution cavity 18 is provided with a first-level air intake hole 16 on the bottom plane, and eight holes with a diameter of 0.2mm are evenly distributed along the circumference on the bottom plane of the annular side wall 12. The secondary air intake hole 17, the secondary air intake hole 17 and the primary air intake hole 16 are staggered to avoid the gas flowing in...

Embodiment 2

[0042] Such as Figure 6-Figure 7As shown, the lightweight integrated anode 1 includes an annular porous material plate 11, an annular inner side wall 12, an annular base 13, an air pipe support 14, an air pipe 15, a primary air intake hole 16, a secondary porous air intake ring 20 and Annular outer wall 21. First, electron beam welding is used to respectively weld the secondary porous intake ring 20 on the annular outer wall 21 (weld e) and the annular inner wall 12 (weld f). Then the annular porous material plate 11 is nested into the U-shaped groove completed by the above welding, and the outer and inner two welds (welds a, b) are welded to form a secondary distribution chamber 19, which is passed through the electron beam The primary distribution cavity 18 is formed on the annular base 13 (welding seam c, d) made of stainless steel by welding, the primary distribution cavity 18 is provided with a primary air intake hole 16 on the bottom plane, and one end of the trachea s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com