Two-dimensional expansion joint

An expansion joint and transverse technology, applied in the field of expansion joints, can solve problems such as compensating two-dimensional displacements of complex expansion joints, and achieve the effects of strong applicability and versatility, flexible quantity and size setting, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

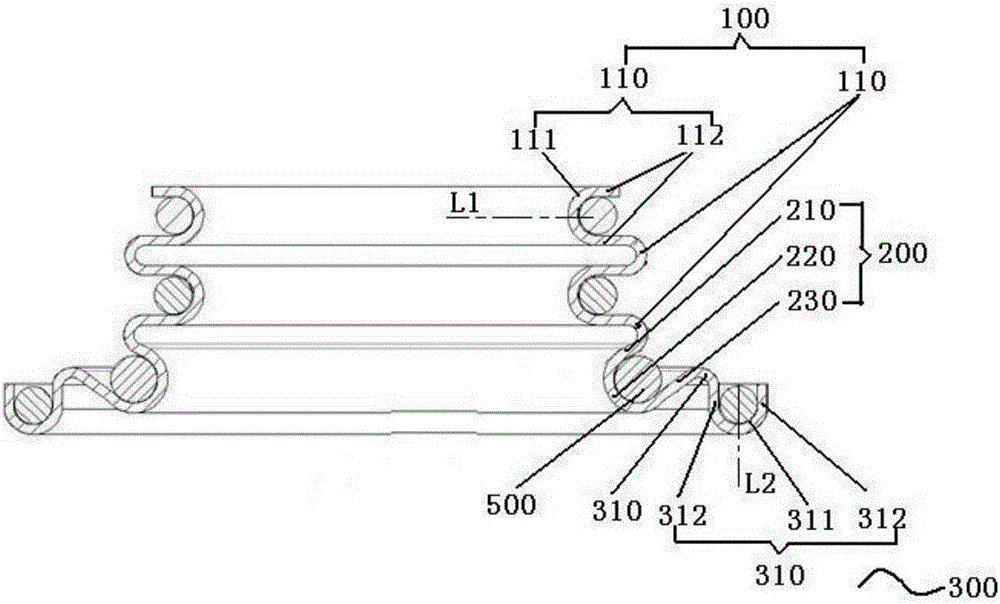

[0042] Such as figure 1 As shown, the two-dimensional expansion joint of this embodiment includes: an expansion joint body;

[0043] The longitudinal section of the expansion joint body includes: a longitudinal corrugated part 100, a connecting part 200 and a transverse corrugated part 300 connected in sequence;

[0044] The longitudinal corrugated portion 100 includes at least one longitudinal corrugated segment 110, each longitudinal corrugated segment 110 includes a longitudinal wave arc segment 111 and a longitudinal wave extension segment 112 connected to the end of the longitudinal wave arc segment 111, the longitudinal wave arc segment 111 The central axis is parallel to the transverse direction;

[0045] The transverse corrugated portion 300 includes at least one transverse corrugated section 310, each transverse corrugated section 310 includes a transverse wave arc section 311 and a transverse wave extension section 312 connected to the end of the transverse wave arc...

Embodiment 2

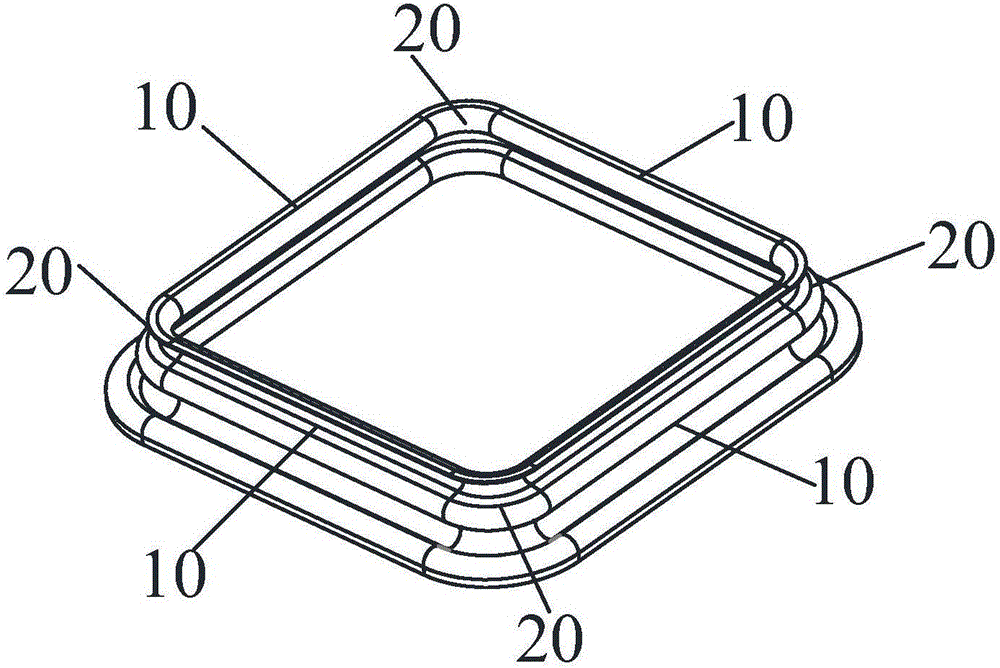

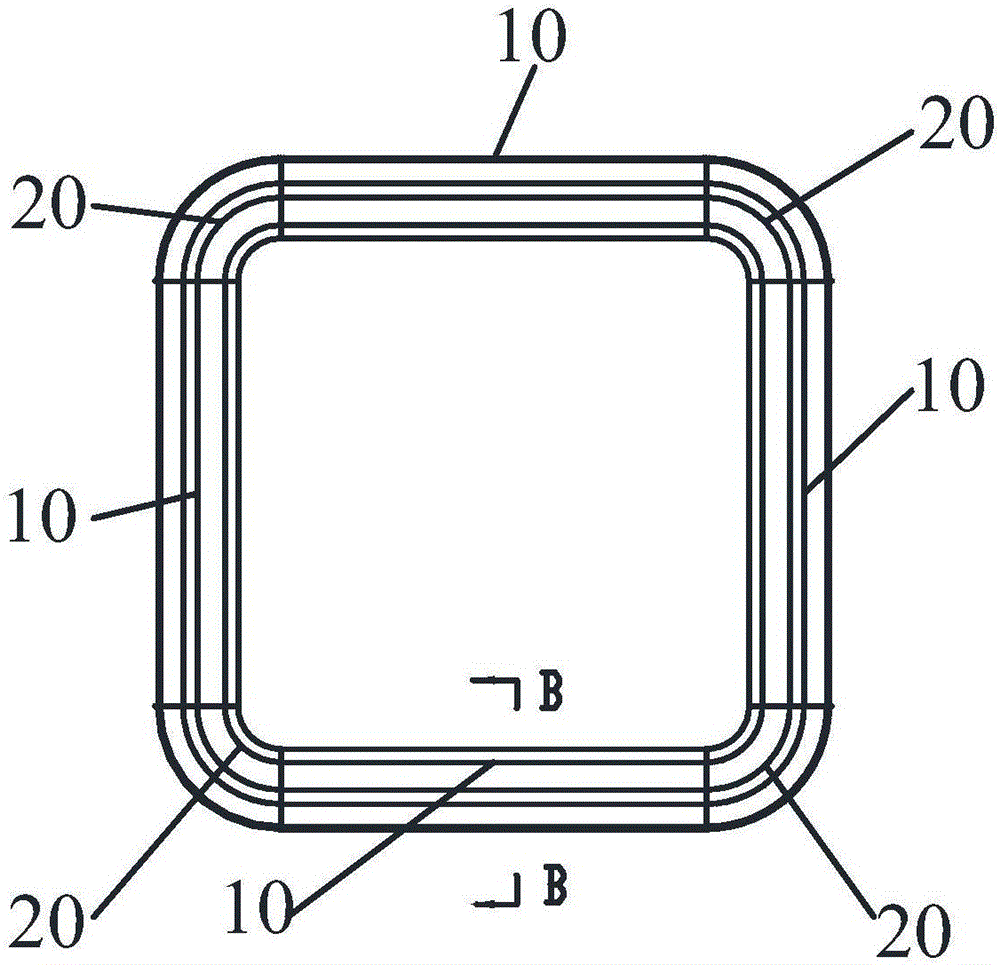

[0061] According to the shape of the position where the amount of thermal expansion needs to be compensated in the equipment, the two-dimensional expansion joint of the present invention can be set as a whole in a straight line, an arc, or a combination of two shapes, such as Figure 2-4 As shown, the overall shape of the transverse cross-section of the two-dimensional expansion joint in this embodiment is rectangular, and the transverse cross-section of the two-dimensional expansion joint includes four sequentially connected linear expansion parts 10, and there is a The arc-shaped expansion part 20, the longitudinal section of the linear expansion part 10 and the arc-shaped expansion part 20 all include a longitudinal corrugated part 100, a connecting part 200 and a transverse corrugated part 300 connected in sequence, wherein the longitudinal corrugated section 110 of the longitudinal corrugated part 100 There are two, and there is one transverse corrugated section 310 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com