A multi-sensor heating network leakage early warning monitoring method

An early warning monitoring and multi-sensor technology is applied in the direction of measuring the increase and decrease rate of fluid, using liquid/vacuum degree for liquid tightness measurement, pipeline system, etc., which can solve the influence of heating load fluctuation, single early warning and monitoring method, Can not be found in time and other problems to achieve the effect of reducing operating costs, improving early warning and anti-interference capabilities, and safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

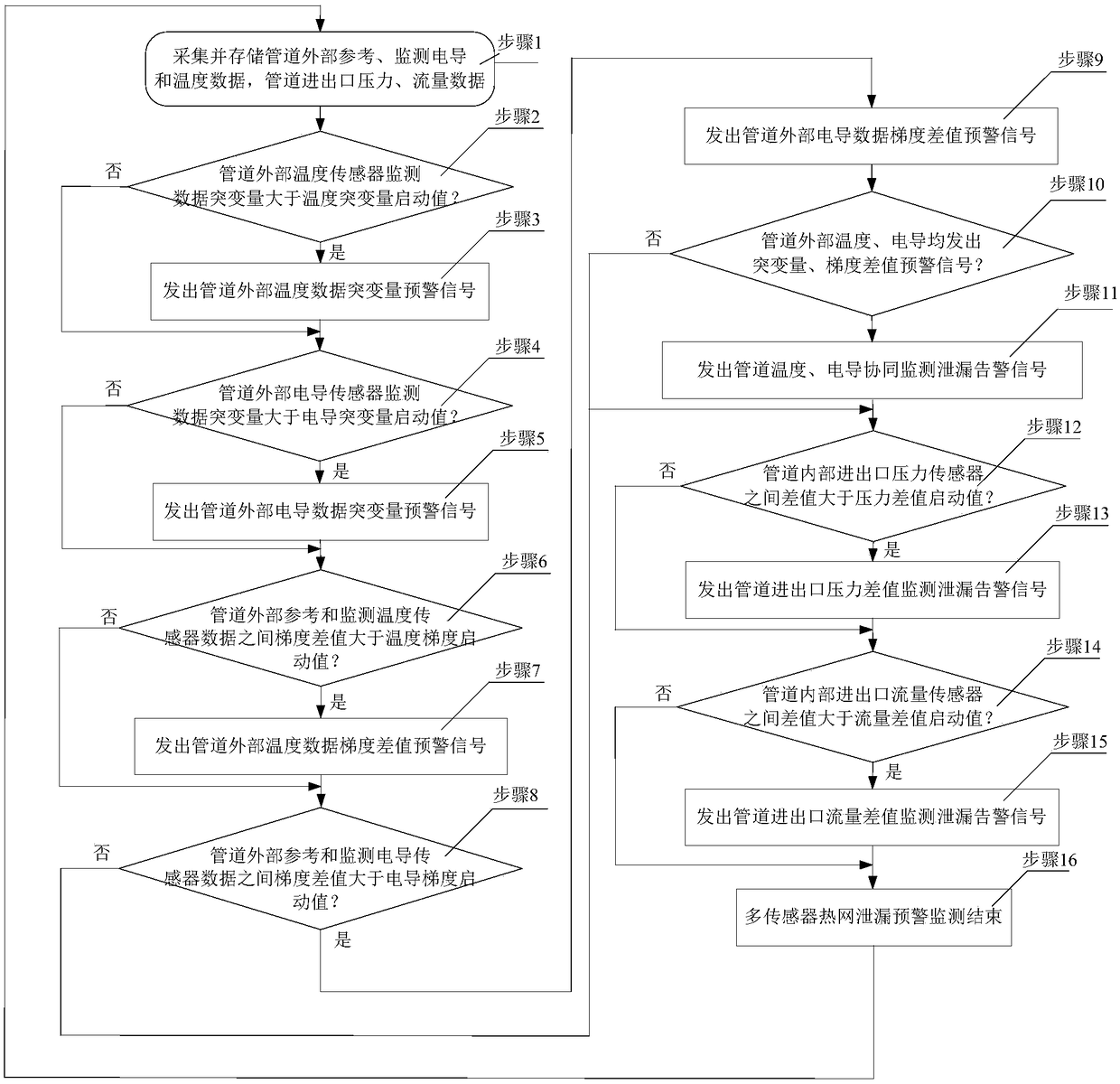

[0041] Such as figure 1 As shown, a multi-sensor heating network leakage early warning monitoring method provided by the present invention includes the following steps:

[0042] 1) Collect and store pipeline external reference and monitor temperature sensor data, pipeline external reference, monitor conductivity sensor data, pipeline internal inlet and outlet pressure, flow sensor data, and enter step 2) after data collection and storage are completed;

[0043] 2) Judge whether the monitoring data mutation of the pipeline external temperature sensor is greater than the temperature mutation start value, if the determination result is yes, go to step 3); if the judgment result is no, it proves that the pipeline external temperature data has no mutation, and then go to step 4);

[0044] 3) Issue an early warning signal for sudden changes i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com