A Method for Rapid Measurement and Stakeout of High-rise Buildings

A technology for surveying lofting and high-rise buildings, applied in the field of architectural surveying and mapping, can solve the problems of lower precision of the main control axis of the construction floor, lower precision of the plummet, and low construction efficiency, so as to avoid secondary construction phenomena, improve accuracy, and improve The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

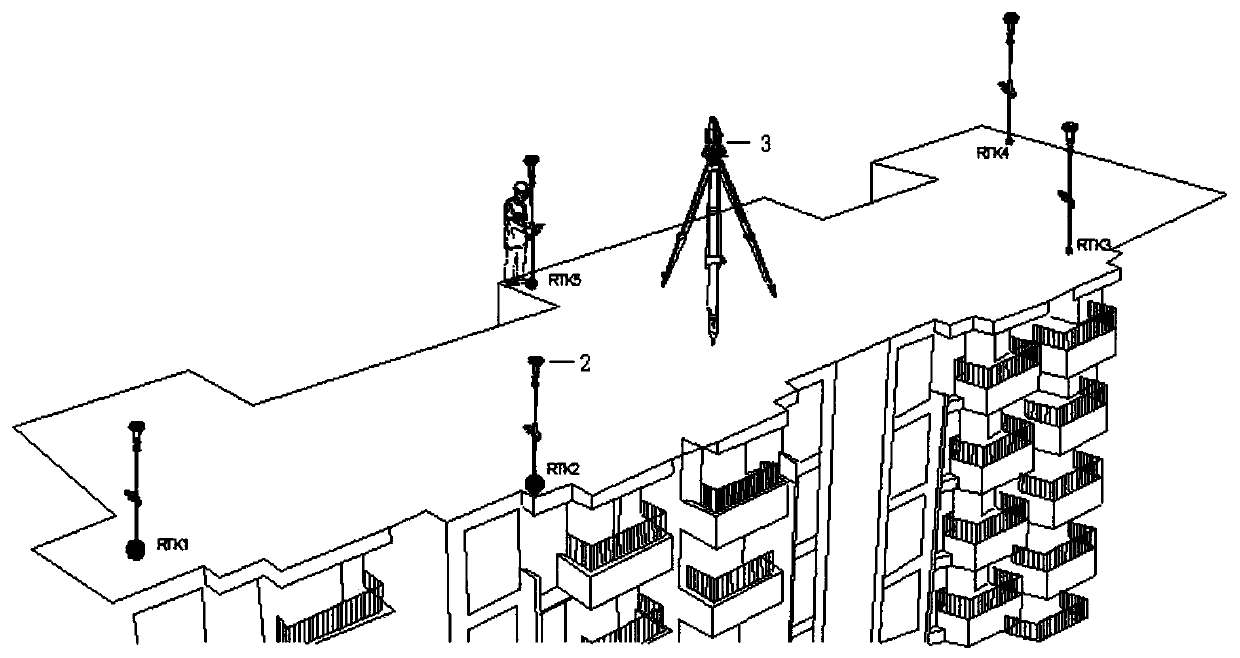

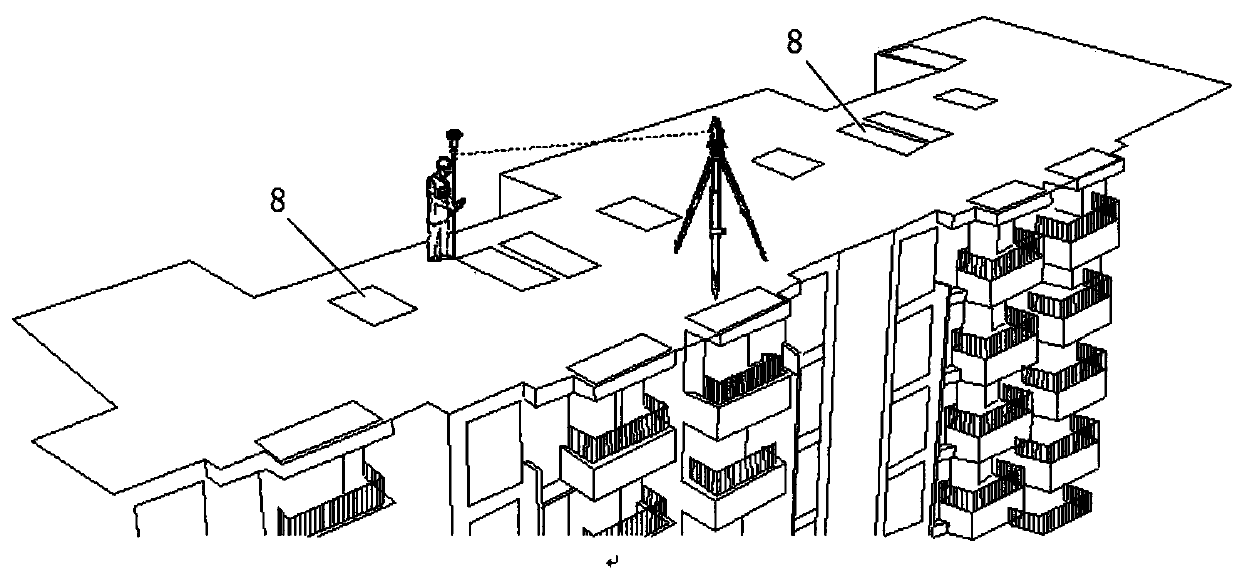

[0027] Set up the GPS-RTK reference station in a relatively open place on the construction site, set up the measurement robot 3 in the middle of the construction floor, and set up the GPS-RTK rover station 2 in any position as far as possible around it.

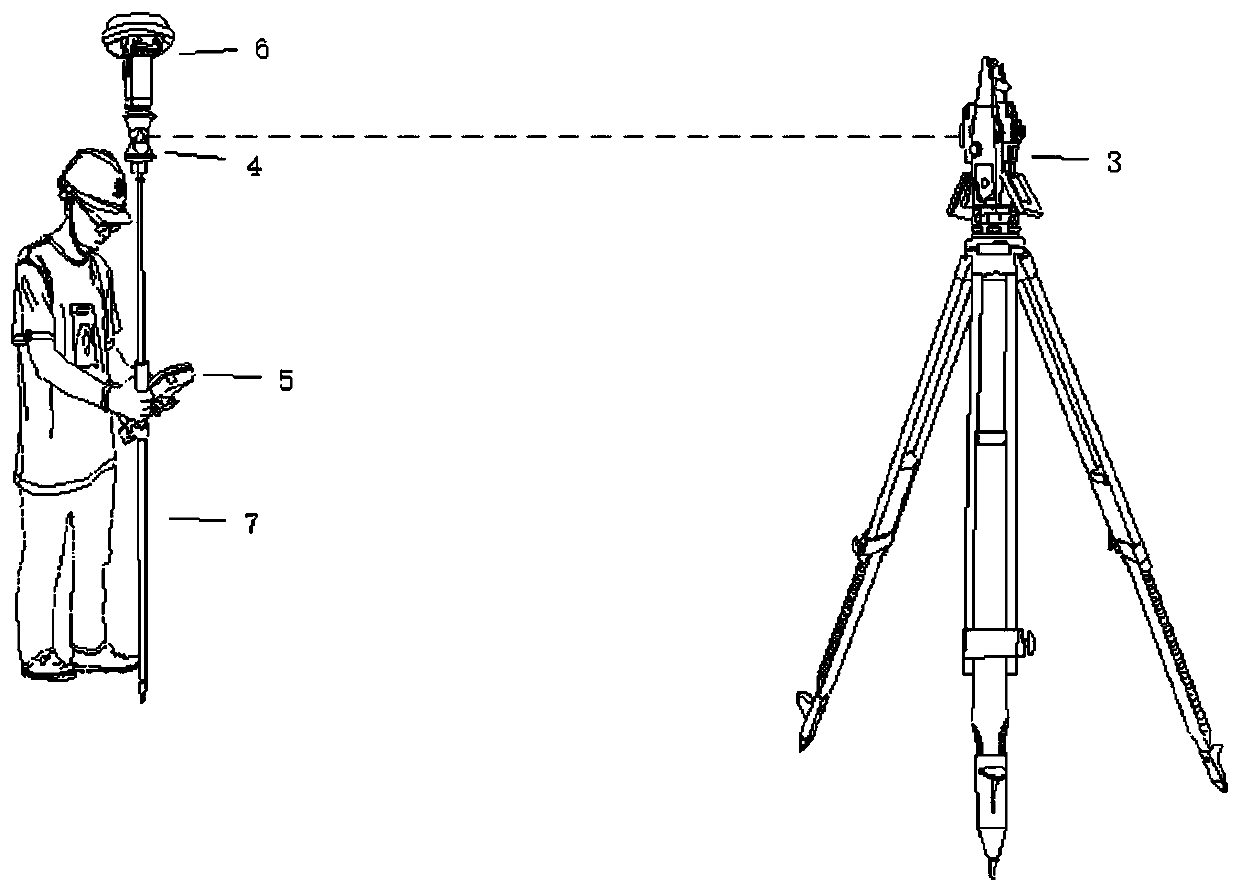

[0028] Such as figure 2 As shown in , the GPS-RTK rover 2 includes a receiver 6 and a connecting rod 7 for support, the upper end of the connecting rod is connected to the receiver through a full prism 4, and the connecting rod is provided with a measurement for generating a BIM model Hand thin 5, the BIM model can automatically generate the structural position that needs to be staked out.

[0029] The inventive method comprises the steps:

[0030] Step 1: Set up a GPS-RTK reference station in an open and interference-free place on the construction site.

[0031] Step 2: Set up the measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com