Synergetic immunity detection method for steam leakage of steam trap of tire vulcanizing machine

An immunological detection method, tire vulcanization technology, applied in the testing of machine/structural components, testing of fluid tightness, measuring devices, etc. Problems such as the severity of valve internal leakage, to overcome the interference of disturbance factors, reduce the missed detection rate and false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

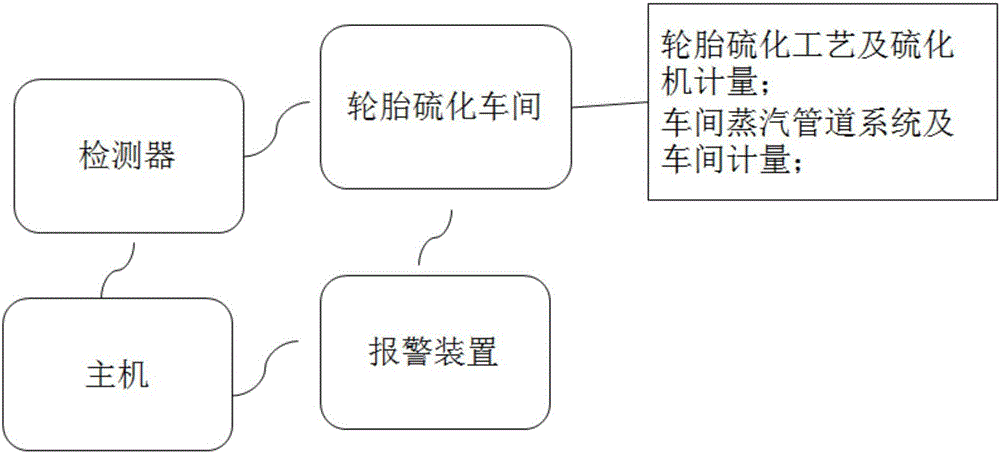

[0051] A kind of synergistic immunological detection method of steam trap internal leakage of tire vulcanizing machine, based on the artificial system of computer, comprises the following steps:

[0052] A: Initialization of the computing host system:

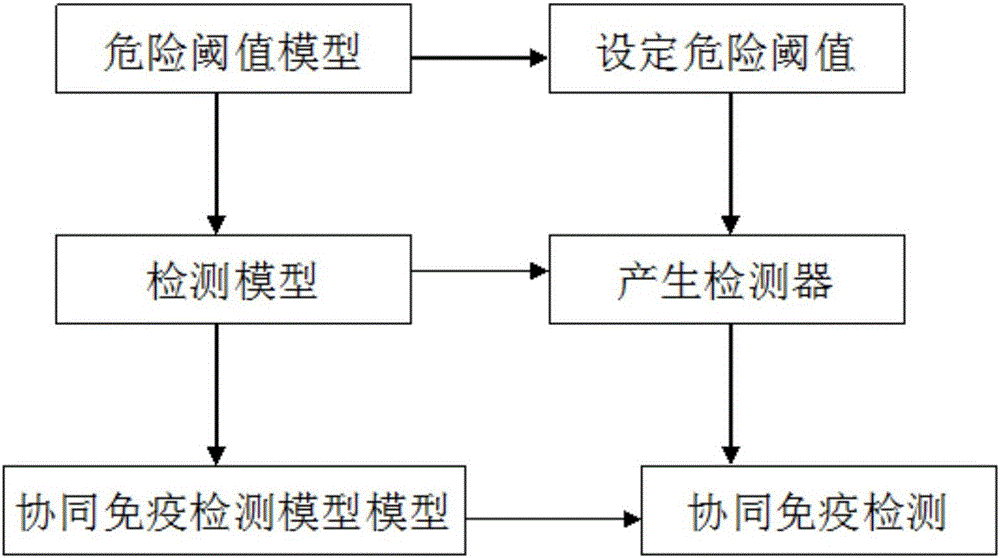

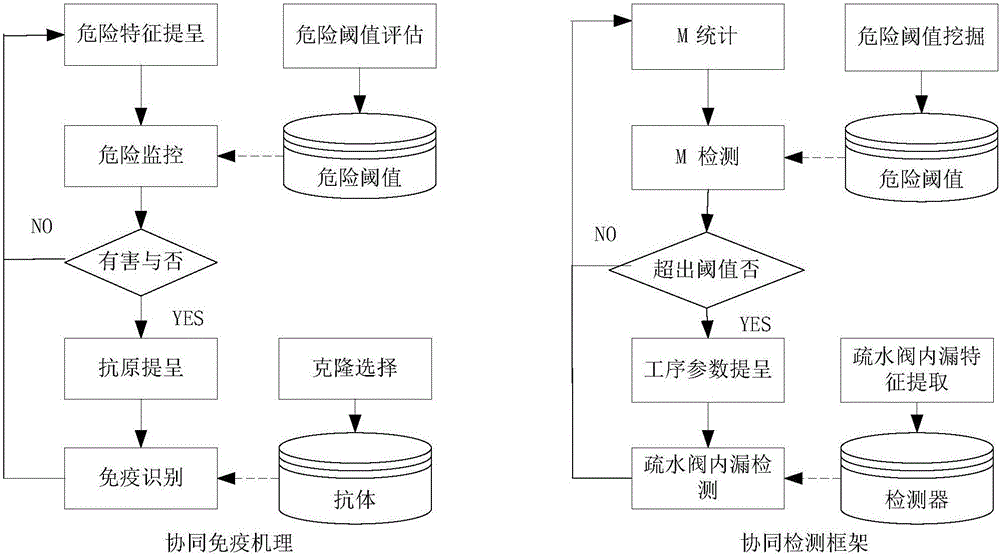

[0053] (1) Construction of the hazard threshold model: by establishing a dynamic baseline regression model between workshop-level steam consumption and equipment-level process parameters, a dynamic hazard baseline is generated and the hazard threshold is set;

[0054] (2) Construction of the detection model: using the state parameters of the vulcanizing machine and the state parameters of the steam pipeline, the detector of the leaking vulcanizing machine is generated through artificial immune network clustering;

[0055] B: Collaborative immunoassa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com